Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

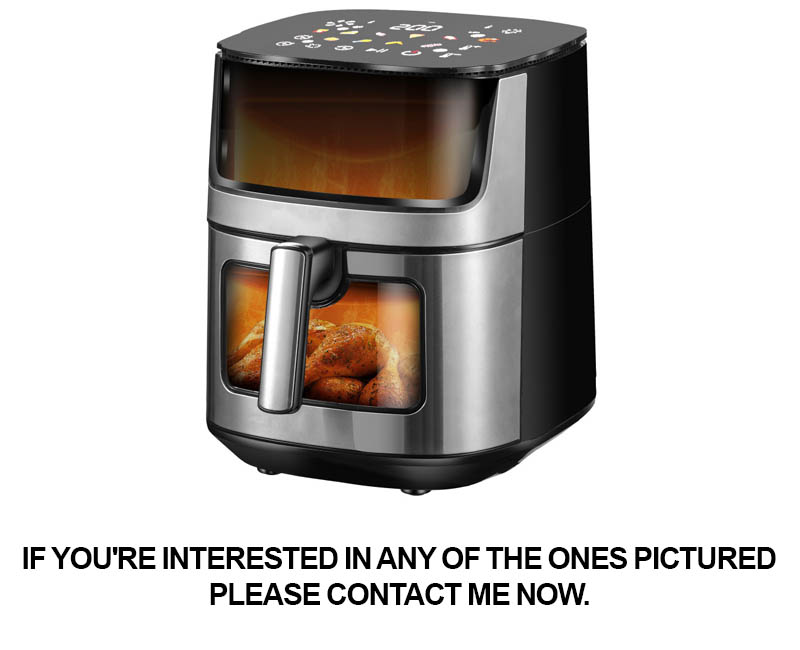

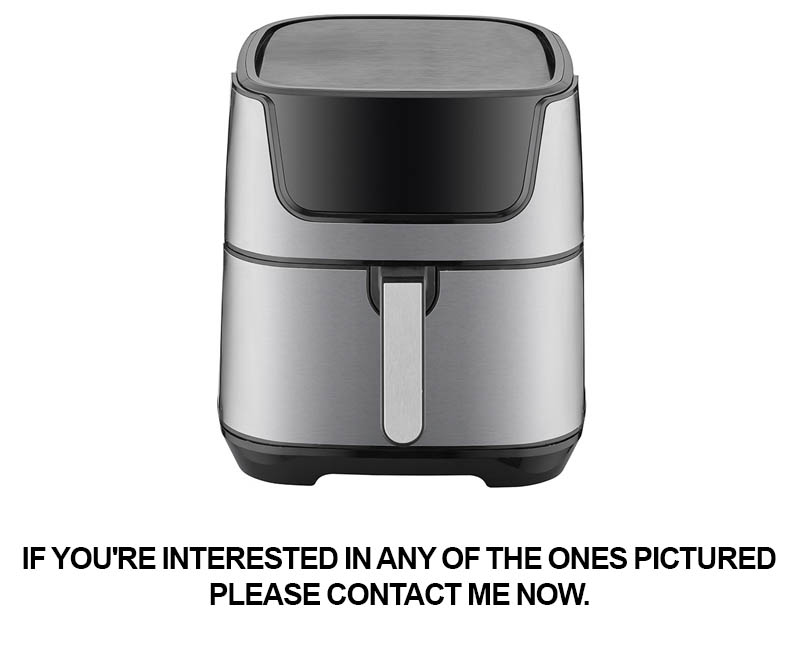

In the ever-evolving landscape of kitchen appliances, one standout product has emerged as a beacon of innovation and convenience: the air fryer. This modern marvel has transformed the way we cook, offering a healthier alternative to traditional frying methods. As the market for air fryers continues to soar, it’s fascinating to explore the cutting-edge designs, market trends, and the cost-effective manufacturing processes that are shaping this burgeoning industry. Let’s delve into the stories of customer successes and envision the future of air fryer technology, where health, efficiency, and sustainability meet.

The air fryer market has experienced an unprecedented surge in popularity over recent years, transforming the landscape of kitchen appliances. This surge can be attributed to several key factors that have converged to make air fryers a staple in modern kitchens worldwide.

Once considered a niche product, air fryers have now become a go-to cooking method for health-conscious consumers and culinary enthusiasts alike. The allure of these appliances lies in their ability to mimic the crispy texture of fried foods without the excessive oil. This not only makes for a healthier cooking alternative but also appeals to the growing number of individuals seeking to reduce their dietary fat intake.

The convenience factor cannot be overlooked. Air fryers are compact, easy to use, and require minimal clean-up, making them a practical choice for busy lifestyles. Their versatility is another selling point, as they can be used to cook a wide variety of foods, from French fries and chicken wings to vegetables and even desserts.

The rise of the air fryer market has been further propelled by the influence of social media and celebrity chefs. Influencers and culinary experts have been quick to embrace the technology, sharing their air fryer recipes and cooking techniques with their followers. This has not only generated buzz around the product but has also inspired a community of home cooks to experiment with their own air fryer creations.

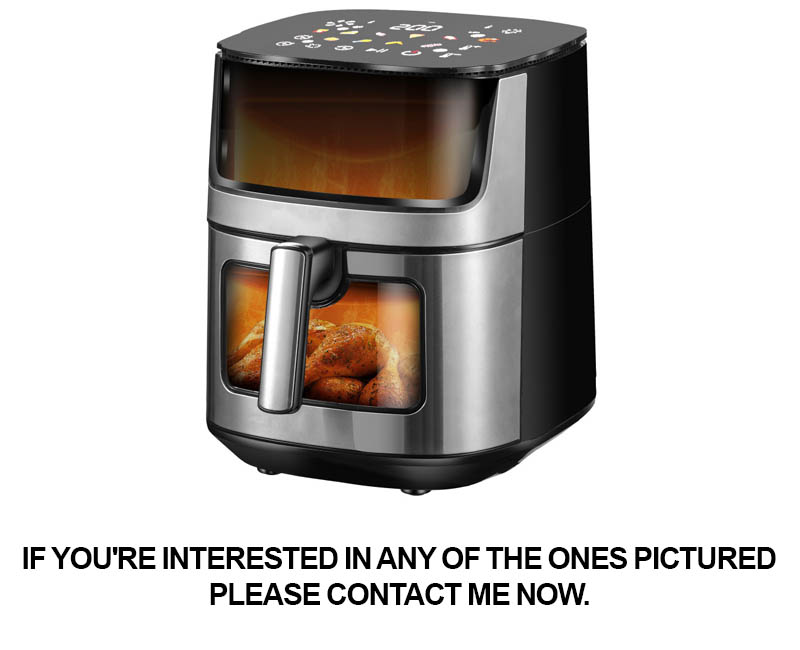

As the market has expanded, so has the competition. Brands have been racing to innovate and improve their air fryer designs, offering features like adjustable temperature controls, larger capacity baskets, and even smart technology integration. This has led to a diverse range of air fryers that cater to different consumer needs and preferences.

Consumer awareness of health and wellness has also played a significant role in the air fryer market’s growth. With the increasing prevalence of chronic diseases like obesity and heart disease, people are more conscious of the foods they eat and how they are prepared. Air fryers offer a solution that allows for the enjoyment of favorite dishes with a fraction of the guilt, making them an attractive option for health-forward consumers.

Additionally, the sustainability movement has contributed to the popularity of air fryers. By reducing the amount of oil used in cooking, these appliances align with the broader environmental and ecological concerns that are shaping consumer choices. The idea of using less oil is not only healthier but also more eco-friendly, appealing to the environmentally conscious consumer.

The retail landscape has also adapted to the air fryer boom. Supermarkets and specialty kitchen stores have dedicated aisles to air fryers, often featuring a range of models from different brands. Online marketplaces have seen a similar surge, with air fryers being one of the top-selling kitchen appliances.

Moreover, the pandemic has accelerated the shift towards home cooking. With more people spending extended periods at home, the need for convenient and healthy cooking solutions has intensified. Air fryers have emerged as a beacon of innovation in this space, offering a way to enjoy a variety of meals without the need for traditional frying methods.

In conclusion, the air fryer market’s rise is a multifaceted phenomenon, driven by health consciousness, convenience, technological innovation, and environmental concerns. As the market continues to evolve, it’s clear that air fryers are here to stay, poised to play a significant role in the future of home cooking.

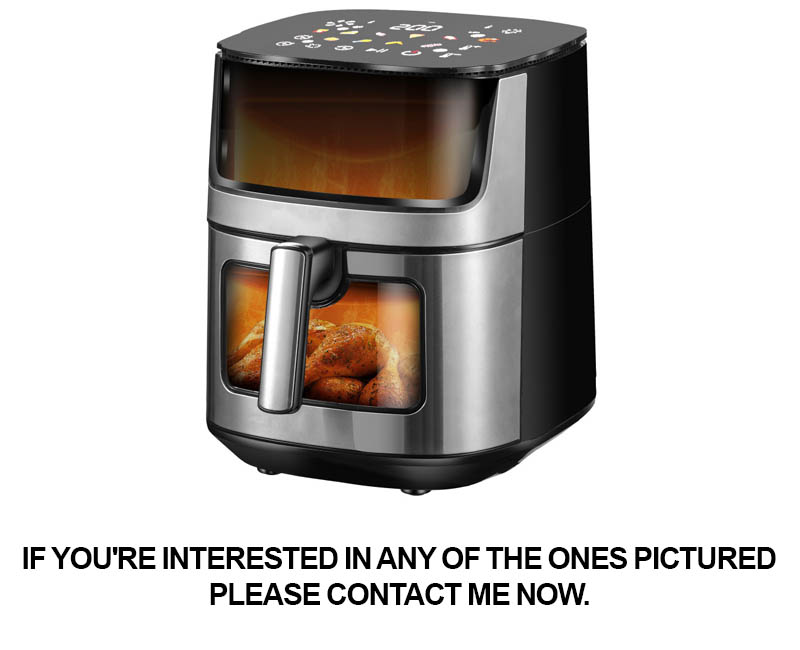

Turnkey solutions are a game-changer in various industries, and the air fryer market is no exception. These comprehensive packages offer a one-stop shop for manufacturers, streamlining the entire process from design to delivery. Here’s a closer look at what turnkey solutions entail and how they benefit the air fryer OEM industry.

In a turnkey solution, the service provider takes full responsibility for every aspect of the product development process. This includes everything from the initial design and engineering to the final manufacturing and packaging. By opting for a turnkey solution, air fryer OEMs can eliminate the need for in-house design teams and external suppliers, simplifying their supply chain management.

The design phase of a turnkey solution is crucial, as it lays the foundation for the entire product. Experienced engineers and designers work closely with the OEM to understand their specific needs and goals. This collaborative approach ensures that the final air fryer design is not only functional and innovative but also aesthetically pleasing and easy to use. The design team also takes into account the latest market trends and consumer preferences, guaranteeing that the product will stand out in a competitive landscape.

One of the key advantages of turnkey solutions is the integration of cutting-edge manufacturing technologies. Advanced machinery and processes are employed to ensure that each air fryer is produced to the highest standards. From precision components to energy-efficient motors, turnkey providers invest in state-of-the-art equipment to deliver high-quality products. This focus on quality control helps air fryer OEMs maintain their reputation for excellence in the marketplace.

Once the design and manufacturing are complete, turnkey solutions also encompass the logistics and distribution aspect. Providers offer efficient shipping and handling services, ensuring that the finished products are delivered to the OEM’s location or directly to their customers. This end-to-end service frees up the OEM’s time and resources, allowing them to focus on other critical aspects of their business.

Customization is another hallmark of turnkey solutions. Air fryer OEMs have the flexibility to tailor the products to their brand’s identity and specific market requirements. From selecting the materials to choosing the color schemes, these solutions enable OEMs to create unique and memorable products that resonate with their target audience. This level of personalization can be particularly valuable in the highly competitive air fryer market, where differentiation is key.

Moreover, turnkey solutions often include after-sales support. Providers may offer technical assistance, warranty services, and customer care, ensuring that the OEM’s customers have a positive experience with the product. This comprehensive support can enhance the OEM’s brand reputation and foster long-term customer loyalty.

In the realm of compliance, turnkey solutions are a breeze. Since these providers are well-versed in industry regulations, they handle certifications and standards compliance on behalf of the OEM. This includes the all-important UL (Underwriters Laboratories) certification, which is crucial for air fryer safety and marketability. By outsourcing these responsibilities, air fryer OEMs can rest assured that their products meet the highest safety standards without the hassle of navigating the regulatory landscape themselves.

Cost management is also a significant benefit of turnkey solutions. By consolidating the design, manufacturing, and distribution processes, providers can achieve economies of scale. This often translates to cost savings for the OEM, who can invest those savings into marketing, research, and development, or even pass the savings on to the end consumer.

In summary, turnkey solutions offer a holistic approach to air fryer manufacturing that is efficient, cost-effective, and flexible. They provide peace of mind to OEMs by taking care of all aspects of product development and delivery, allowing them to focus on what they do best: bringing innovative and safe air fryer products to market.

In today’s fast-paced and safety-conscious world, the importance of UL certification for kitchen appliances, particularly air fryers, cannot be overstated. This section delves into why UL certification is a crucial aspect for manufacturers and consumers alike.

The first layer of importance lies in the assurance of safety. UL certification is a stamp of approval that a product has been rigorously tested and meets stringent safety standards. For air fryers, this means that every component, from the heating element to the exterior housing, has been examined to ensure it doesn’t pose a fire hazard or electrical risk.

Consumers often prioritize convenience over everything else when shopping for kitchen appliances. However, this convenience should not come at the expense of safety. UL certification provides peace of mind, assuring buyers that the air fryer they are purchasing has been vetted for potential risks, such as overheating or electrical failures.

Another critical aspect is compliance with regulations. Different regions and countries have their own safety standards and regulations. UL certification is globally recognized, which means that a product bearing the UL mark is compliant with a wide range of international standards. This allows manufacturers to easily expand their market reach without having to go through the lengthy process of obtaining multiple certifications for different markets.

For manufacturers, the UL certification process can also serve as a quality control tool. During the certification process, products are subjected to a series of tests that can uncover any manufacturing defects or design flaws. This proactive approach helps to identify and rectify issues before they reach the consumer, enhancing the overall reputation of the brand.

Moreover, the UL certification process is not a one-time event. It involves ongoing compliance checks, which means that manufacturers are continuously monitored to ensure that their products maintain the high standards set by UL. This ongoing oversight can help maintain product integrity over time, as manufacturers are incentivized to maintain quality standards.

In the case of air fryers, which often involve high temperatures and electrical currents, the risk of malfunction is a significant concern. UL certification addresses this by ensuring that the appliances have been designed with safety features that prevent accidents and injuries. For instance, UL-certified air fryers must have proper insulation, grounded outlets, and effective temperature controls to prevent overheating.

From a consumer’s perspective, the presence of the UL certification mark is a signal that the product has been independently evaluated. This independent verification can be particularly reassuring, as it comes from a third-party organization that is not affiliated with the manufacturer. It adds a layer of trust to the product, making it more attractive to buyers who value reliability and safety.

Lastly, in the event of a recall or a product liability issue, having UL certification can be a lifesaver. If a manufacturer needs to recall a product, having the UL certification can help streamline the process and ensure that the affected units are identified quickly and efficiently. This can mitigate potential damage to the brand and consumer confidence.

In summary, the importance of UL certification for air fryers and other kitchen appliances is multifaceted. It guarantees safety, ensures compliance with international standards, serves as a quality control measure, maintains product integrity over time, provides trust to consumers, and aids in efficient recall processes. For manufacturers and consumers, UL certification is more than just a certification; it’s a symbol of trust, reliability, and commitment to safety.

Navigating the complexities of the kitchen appliances market can be daunting, especially for Original Equipment Manufacturers (OEMs) looking to enter the air fryer industry. That’s where our turnkey air fryer OEM service comes into play, offering a comprehensive solution that takes the guesswork out of production and quality assurance. Here’s what makes our service stand out:

Customization at its CoreOur turnkey service is designed to cater to the unique needs of each client. We offer a range of customizable air fryer models, from compact countertop units to commercial-grade appliances. This flexibility allows OEMs to create products that resonate with their target market, whether it’s focusing on health-conscious consumers or those seeking convenience.

Innovative Design and TechnologyWe pride ourselves on staying at the forefront of air fryer technology. Our design team collaborates closely with clients to integrate the latest innovations, such as smart features, energy-efficient components, and user-friendly interfaces. This ensures that the air fryers we produce are not only safe and compliant with industry standards but also cutting-edge in terms of functionality.

Comprehensive Production SupportFrom the initial design phase to the final product launch, our turnkey service provides end-to-end support. We manage the entire production process, including sourcing high-quality materials, overseeing manufacturing, and ensuring that every air fryer meets our stringent quality control standards. This hands-off approach allows OEMs to focus on their core business while we handle the intricacies of production.

Quality Assurance and Safety ComplianceSafety is paramount in the kitchen appliances industry, and our turnkey service is built on a foundation of rigorous quality assurance. We work closely with Underwriters Laboratories (UL) to ensure that all our air fryers are certified to meet the highest safety standards. This not only protects consumers but also gives OEMs peace of mind that their products will pass any regulatory scrutiny.

Efficient Supply Chain ManagementEfficiency is key in today’s fast-paced market. Our turnkey service includes streamlined supply chain management, ensuring that materials are sourced quickly and manufacturing is completed on time. This just-in-time approach minimizes lead times and reduces inventory costs, giving OEMs a competitive edge.

Custom Packaging and BrandingAesthetics matter, and our service extends to custom packaging and branding. We understand that a product’s presentation is as important as its performance. Our team works with clients to design packaging that not only protects the air fryer but also enhances its appeal on store shelves. We also offer branding services to ensure that the final product reflects the client’s brand identity.

Ongoing Technical SupportOnce the air fryers are in the hands of consumers, our support doesn’t end. We provide ongoing technical assistance to address any issues that may arise, ensuring that the OEM’s reputation for quality and reliability is maintained. This includes providing spare parts and troubleshooting guidance.

Global Reach and Market AccessOur turnkey service is not limited to a single region. We have the capabilities to produce air fryers that meet the specific requirements of international markets, including certifications and compliance with local standards. This global reach opens up new opportunities for OEMs looking to expand their customer base.

Cost-Effective SolutionsWe understand that cost is a critical factor for OEMs. Our turnkey service is designed to be cost-effective without compromising on quality. By managing the production process efficiently and leveraging economies of scale, we can offer competitive pricing without sacrificing the performance or safety of the air fryers.

In summary, our turnkey air fryer OEM service is a one-stop solution that combines innovative design, quality assurance, efficient production, and comprehensive support. Whether you’re a small startup or an established manufacturer, our service is tailored to help you bring high-quality, safe, and market-ready air fryers to your customers.

In the ever-evolving landscape of kitchen appliances, air fryers have emerged as a game-changer, offering a healthier alternative to traditional frying methods. As we delve into the realm of innovation, here are some cutting-edge design ideas that are poised to revolutionize the air fryer market:

Smart ConnectivityIntegrating smart technology into air fryers allows users to control their appliances remotely via smartphones or smart home systems. Imagine being able to start your air fryer while you’re still at work, ensuring a hot meal is ready as you walk through the door.

Modular ComponentsDesigning air fryers with modular components means users can upgrade or replace parts as needed. This not only extends the life of the appliance but also allows for customization based on personal preferences and usage patterns.

Aesthetically PleasingThe aesthetic appeal of an air fryer can be a significant factor in its popularity. Sleek, modern designs with touch controls and LED displays can make a kitchen look more sophisticated and tech-forward.

Energy EfficiencyInnovative insulation and heat distribution systems can greatly improve the energy efficiency of air fryers. By reducing energy consumption, these designs not only save money but also contribute to a greener planet.

Versatile Cooking OptionsExpanding the capabilities of air fryers beyond the basics can attract a wider audience. Consider a model that can also dehydrate, bake, or even grill, offering a multi-functional cooking experience in one appliance.

Customizable Cooking PresetsOffering a range of pre-programmed settings tailored to different types of food can simplify the cooking process. Users can select a preset for chicken, fish, vegetables, or even desserts, with the air fryer adjusting the temperature and cooking time accordingly.

Smart SensorsIncorporating smart sensors that can detect food moisture levels can ensure the perfect crispness without overcooking. These sensors can also alert the user when the food is ready, reducing the need for constant monitoring.

Non-Stick InnovationWhile non-stick coatings are standard in air fryers, there’s always room for improvement. Developing a new, more durable non-stick surface that doesn’t degrade over time can be a significant selling point.

Child Safety LocksFor those with young children, a built-in child safety lock can prevent accidental operation. This feature would provide peace of mind and make the appliance safer for all household members.

Eco-Friendly PackagingThe packaging of the air fryer can also be a part of its design innovation. Using sustainable materials and minimizing waste can appeal to environmentally conscious consumers.

Interactive Cooking GuidesPairing the air fryer with an interactive cooking guide app can provide users with step-by-step instructions, nutritional information, and even recipes. This can be particularly helpful for beginners or those looking to expand their culinary skills.

Health MonitoringFor those who are health-conscious, a design that includes health monitoring features, such as tracking calorie intake or nutritional content, can be a valuable addition.

Customizable Cooking RacksOffering adjustable or removable cooking racks can cater to a variety of food sizes and shapes, making the air fryer more versatile for different types of meals.

Energy-Saving ModesIntroducing energy-saving modes that automatically turn off the appliance after a certain period of inactivity can help conserve energy and reduce electricity bills.

Interactive Learning FeaturesFor tech-savvy users, incorporating interactive learning features that can teach users about different cooking techniques or the science behind air frying can be an engaging addition to the appliance.

By focusing on these innovative design ideas, manufacturers can create air fryers that not only meet the needs of today’s consumers but also anticipate their future desires, ensuring a place in the hearts and kitchens of millions.

In the ever-evolving landscape of kitchen appliances, staying abreast of market trends is crucial for success. Here’s a glimpse into the current trends and data analysis shaping the air fryer market:

Air fryers have become a staple in modern kitchens, thanks to their ability to cook with less oil than traditional deep-frying methods. This shift towards healthier cooking options has been a significant driver of market growth. According to a report by Grand View Research, the global air fryer market is expected to reach a value of $7.9 billion by 2025, with a projected CAGR of 8.5% from 2018 to 2025.

One key trend is the integration of smart technology. Consumers are increasingly looking for appliances that can be controlled remotely or via voice commands, offering convenience and efficiency. This has led to the rise of smart air fryers that can connect to Wi-Fi and be managed through smartphones or smart home systems.

Design has also played a pivotal role in the market’s growth. Air fryers are now sleeker, more compact, and come in a variety of colors and finishes to complement different kitchen aesthetics. The demand for eco-friendly and sustainable materials is on the rise, with manufacturers exploring options like bamboo handles and recycled plastic bodies.

Another trend is the customization of air fryers to cater to specific dietary preferences. With the surge in popularity of vegan and gluten-free diets, manufacturers are introducing air fryers with additional features such as adjustable temperature controls and pre-programmed settings for different types of food.

Data analysis from market research firms like Euromonitor International reveals that the North American market has been the largest consumer of air fryers, with the U.S. leading the way. However, emerging markets such as China and India are expected to see significant growth due to increasing urbanization and rising incomes.

Health and wellness are at the forefront of consumer concerns, and this is reflected in the air fryer market. Data from Statista indicates that the health-conscious consumer segment is driving the demand for air fryers, as they offer a way to enjoy fried foods with fewer calories and less fat.

Energy efficiency is also a crucial factor. As environmental consciousness grows, manufacturers are focusing on creating air fryers that consume less energy, thereby reducing the carbon footprint of their products. The Energy Star certification is becoming a sought-after label for energy-efficient appliances.

The market is also witnessing a surge in the use of air fryers for commercial purposes. Restaurants and cafes are incorporating these appliances into their kitchens to offer healthier alternatives to customers who are becoming more health-conscious.

In conclusion, the air fryer market is shaped by a confluence of technological advancements, changing consumer preferences, and a focus on health and sustainability. As these trends continue to evolve, manufacturers must adapt and innovate to meet the demands of a consumer base that is more informed and discerning than ever before.

In the realm of kitchen appliances, the air fryer has emerged as a game-changer. These devices have become a staple in modern kitchens, offering a healthier alternative to traditional frying methods. Ensuring that these products meet the highest safety and quality standards is paramount, which is where rigorous quality assurance and testing come into play.

The process begins with sourcing high-quality components that are reliable and durable. Each part, from the heating element to the non-stick coating, must be carefully selected to ensure the air fryer’s performance and longevity. Our team meticulously evaluates suppliers to guarantee that every component adheres to our stringent quality criteria.

Our in-house testing lab is equipped with state-of-the-art equipment to simulate real-world conditions. We subject our air fryers to a variety of tests to ensure they can withstand the demands of everyday use. These tests include:

Beyond the physical testing, we also conduct quality checks at various stages of the manufacturing process. This includes visual inspections, where our skilled technicians examine the units for any defects, such as dents, scratches, or misalignments. We also perform functional tests to ensure that all buttons and controls operate smoothly and that the air fryer operates at the correct temperature.

One crucial aspect of quality assurance is compliance with international safety standards, which is where UL certification comes into play. Our air fryers undergo thorough testing to meet the stringent requirements set by UL, an independent organization recognized globally for its safety science expertise. This certification not only provides peace of mind to consumers but also differentiates our products in the competitive market.

Moreover, we take pride in our commitment to sustainability. Our manufacturing process is designed to minimize waste and reduce our environmental footprint. We use energy-efficient equipment and recycle materials whenever possible.

Our quality assurance and testing protocols are not just about meeting standards; they are about exceeding them. We understand that the air fryer is a product that people use every day, and our goal is to ensure that it not only performs flawlessly but also offers a safe and enjoyable cooking experience. By investing in these rigorous processes, we are confident that our customers will receive a product that stands out for its quality, reliability, and peace of mind.

In the competitive world of kitchen appliances, cost-effectiveness is a cornerstone for success. When it comes to manufacturing air fryers, finding the right balance between quality and affordability is crucial. Here’s how we ensure a cost-effective manufacturing process:

Streamlined Production LinesOur factory employs state-of-the-art production lines that are designed for efficiency. By automating certain processes, we reduce the potential for human error and optimize the use of resources, leading to lower production costs.

Bulk Purchasing of Raw MaterialsWe leverage our scale to negotiate bulk discounts on raw materials such as plastic, metal, and electronic components. This not only reduces the cost per unit but also ensures a consistent supply chain, minimizing delays and additional expenses.

Lean Manufacturing PracticesImplementing lean manufacturing principles helps us eliminate waste and reduce costs. By continuously improving our processes, we’re able to produce more with less, cutting down on overhead and operational expenses.

Customization Without CompromiseOur approach to customization is designed to be cost-effective. We offer a range of standard models with various features that can be tailored to meet specific market demands, allowing customers to get the product they want without incurring the high costs of completely custom designs.

Energy-Efficient Production FacilitiesWe’ve invested in energy-efficient equipment and practices to reduce our operational costs. From LED lighting to energy-saving machines, these measures not only lower our utility bills but also demonstrate our commitment to sustainability.

Skilled Workforce TrainingBy investing in the training and development of our workforce, we ensure that our employees are equipped with the skills needed to work efficiently. This reduces the risk of defects and rework, which can drive up costs.

Just-In-Time Inventory ManagementWe use a just-in-time inventory system to manage our stock levels. This approach minimizes the amount of inventory we hold, reducing storage costs and the risk of obsolescence.

Quality Control Without OverkillOur quality control processes are rigorous yet efficient. We use statistical process control to monitor and improve our production processes, ensuring that we’re not spending extra on unnecessary quality checks.

Shorter Lead TimesOur streamlined operations allow us to offer shorter lead times without compromising on quality. This flexibility is attractive to customers who need to meet tight deadlines or respond quickly to market demands.

Continuous Improvement CultureWe foster a culture of continuous improvement, where every employee is encouraged to suggest ways to reduce costs and enhance efficiency. This bottom-up approach ensures that cost-saving measures are identified and implemented throughout the organization.

By focusing on these aspects, we’re able to provide our clients with high-quality air fryers at competitive prices. This cost-effective manufacturing strategy not only benefits our customers but also allows us to remain competitive in the dynamic kitchen appliances market.

Our clients have seen remarkable results by partnering with us. One such story is that of EcoChef Appliances, a startup that was struggling to enter the competitive kitchen appliance market. Their innovative air fryer design was a hit with consumers, but they faced challenges in scaling up production without compromising on quality. By utilizing our turnkey air fryer OEM service, EcoChef was able to quickly bring their product to market. The streamlined manufacturing process allowed them to maintain high-quality standards while meeting the growing demand. The feedback from EcoChef’s customers was overwhelmingly positive, with many praising the durability and performance of the air fryer. This success story is just one example of how our services can transform a promising product into a market leader. Another client, HealthyHome, a well-established brand in the health and wellness sector, approached us to develop a line of air fryers that align with their eco-friendly ethos. Our team collaborated closely with HealthyHome’s designers to create a range of air fryers that were not only energy-efficient but also aesthetically pleasing. The end result was a collection that resonated with the brand’s target audience, leading to increased sales and customer loyalty. We’ve also had the pleasure of working with independent entrepreneurs who have turned their passion projects into thriving businesses. One such individual, Sarah, a fitness enthusiast, had a vision for a compact air fryer that could be easily transported for camping trips or travel. Our turnkey service allowed Sarah to bring her vision to life, and the product was a hit at outdoor retail fairs and online. These success stories underscore the versatility and reliability of our turnkey air fryer OEM service. From small startups to established brands, we’ve helped turn innovative ideas into marketable products, each with its unique set of challenges and triumphs. Our clients’ achievements serve as a testament to our commitment to quality and customer satisfaction.

The air fryer market has seen a remarkable transformation, evolving from a niche appliance to a staple in modern kitchens. As consumers increasingly seek healthier cooking alternatives, the demand for air fryers has surged. These devices have become a favorite for their ability to create crispy, fried foods with minimal oil, making them a hit among health-conscious consumers. The market’s growth is further fueled by the convenience they offer, as they save time and energy compared to traditional deep fryers.

The sleek design and compact size of modern air fryers have also contributed to their popularity. They are not just kitchen gadgets; they are stylish additions to any countertop. This shift in consumer preference has prompted manufacturers to innovate and offer a variety of models, each with unique features and capabilities.

Innovation in technology has allowed for the integration of smart features, such as Wi-Fi connectivity and voice control, making air fryers not just a cooking appliance but also a smart kitchen device. Users can now control their air fryers remotely, receive cooking notifications, and even set recipes through their smartphones or smart speakers.

The market data paints a vivid picture of this growth. According to a report by Grand View Research, the global air fryer market is expected to reach a value of USD 3.5 billion by 2025, growing at a Compound Annual Growth Rate (CAGR) of 8.4% from 2019 to 2025. This trajectory underscores the market’s dynamic nature and the potential for further expansion.

In this landscape, the importance of turnkey solutions for air fryer OEMs cannot be overstated. These solutions offer a comprehensive package that includes design, manufacturing, quality assurance, and certification. By opting for a turnkey service, OEMs can focus on what they do best—branding and marketing—while leaving the technical aspects to experts.

A turnkey solution ensures that all components of the air fryer are thoroughly tested and meet stringent safety standards. This not only protects the end consumer but also builds trust in the brand. With the rise of health and wellness trends, consumers are more likely to invest in products that have been certified by reputable organizations like UL (Underwriters Laboratories).

Introducing our turnkey air fryer OEM service, we pride ourselves on offering a seamless and efficient process. From concept to completion, we provide a range of services that cater to the unique needs of our clients. Our design team collaborates closely with OEMs to bring their vision to life, ensuring that every air fryer is not just functional but also aesthetically pleasing.

Our state-of-the-art manufacturing facilities are equipped with the latest technology to produce air fryers that are both efficient and durable. We understand that quality is paramount, which is why we implement rigorous quality control measures at every stage of production. This commitment to excellence ensures that our clients receive products that meet or exceed industry standards.

When it comes to cutting-edge design ideas, we believe in pushing boundaries. We integrate innovative features such as variable temperature controls, programmable cooking times, and even integrated storage solutions. Our designs are not just ahead of the curve; they are inspired by consumer feedback and market trends.

Market trends and data analysis play a crucial role in shaping our offerings. We continuously monitor consumer behavior and preferences to stay ahead of the competition. This approach has allowed us to anticipate the next big thing in the air fryer market and adapt our products accordingly.

Quality assurance and testing are the cornerstones of our turnkey service. We conduct thorough inspections and tests to ensure that every air fryer meets the highest safety and performance standards. This includes electrical safety, overheating protection, and durability testing. Our commitment to quality is what sets us apart from the competition.

In terms of cost-effective manufacturing, we leverage economies of scale and efficient supply chain management to offer competitive pricing without compromising on quality. Our clients benefit from our expertise in sourcing high-quality materials at the best possible prices, ensuring that their products are not only cost-effective but also sustainable.

Customer success stories are a testament to the effectiveness of our turnkey air fryer OEM service. One such story involves a mid-sized appliance manufacturer that partnered with us to develop a new line of air fryers. The collaboration resulted in a product that not only met but exceeded the market expectations. The new line was a huge success, with the manufacturer experiencing a significant boost in sales and market share.

As we look to the future, the air fryer market is poised for even more innovation. Advancements in technology are expected to bring about new features and functionalities that will further enhance the user experience. One such advancement is the integration of IoT (Internet of Things) capabilities, allowing air fryers to be part of a larger smart kitchen ecosystem.

Another trend we’re watching closely is the customization of air fryers. Consumers are increasingly looking for products that cater to their specific needs and preferences. This could mean offering different sizes, power outputs, or even customizable cooking programs. By staying attuned to these trends, we aim to continue leading the way in air fryer technology.

In conclusion, the future of air fryer technology is bright, with endless possibilities for innovation. Our turnkey air fryer OEM service is designed to help manufacturers navigate this evolving landscape, ensuring that their products are not just competitive but also future-proof. By staying ahead of the curve and focusing on quality, we are confident that we can continue to drive success for our clients in the years to come.