Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In recent years, the landscape of kitchen appliances has been rapidly evolving, with automation playing a pivotal role in shaping the future of these technologies. Among the innovations that have emerged, the automated assembly line for air fryers stands out as a testament to how advanced manufacturing can revolutionize not only production efficiency but also the way consumers interact with their appliances. As we delve into the intricate workings of these assembly lines, the story of their rise becomes a compelling narrative of progress and the relentless pursuit of culinary excellence.

The rise of automated air fryer assembly lines has been nothing short of remarkable. Once a niche product, air fryers have now become a staple in many kitchens around the world. This shift is largely due to the advancements in technology that have allowed for the creation of these efficient, space-saving, and health-conscious cooking appliances. Let’s delve into how this transformation has come to be.

The process of air frying, which uses hot air to circulate around food, has been around for decades. However, it was the integration of automated technology into the assembly line that brought air fryers to the forefront of the kitchen appliance market. These lines are a marvel of modern engineering, where precision and speed meet to produce a high-quality product.

The heart of an automated air fryer assembly line is its machinery. Robots and advanced equipment work in concert to perform tasks that were once the domain of human hands. From the initial stages of unboxing raw materials to the final quality check, every step is meticulously controlled to ensure consistency and efficiency.

Once the components arrive at the assembly line, the process begins with precision cutting and shaping. Metal sheets are transformed into fryer bodies, while electronic components are meticulously placed and soldered. The precision of these machines means that every air fryer that rolls off the line is virtually identical to the last, ensuring a high standard of quality.

The next phase involves the assembly of the internal components. Motors, fans, and heating elements are all carefully fitted into place. Sensors and software ensure that these parts are aligned correctly and that the fryer operates at optimal temperatures. This level of automation not only reduces the risk of human error but also allows for complex configurations that enhance the performance of the air fryer.

As the assembly progresses, the air fryers are subjected to rigorous testing. Automated systems check for leaks, electrical integrity, and thermal performance. These tests are not only thorough but also fast, allowing for rapid feedback and correction if any issues arise.

Once the assembly is complete, the air fryers move on to the finishing touches. This includes applying protective coatings, labels, and packaging. The lines are designed to handle large volumes, with conveyors and robotic arms working seamlessly to package each unit efficiently.

The impact of these automated assembly lines has been profound. For manufacturers, the benefits are clear. Increased production speeds mean that more units can be sold, and the cost savings from reduced labor and waste are significant. This has allowed companies to offer air fryers at more competitive prices, making them accessible to a wider audience.

For consumers, the advantages are equally compelling. The consistency and reliability of air fryers produced on these lines mean that every product performs as advertised. The reduction in manual labor also translates to a safer working environment for assembly line workers, with fewer repetitive strain injuries.

Moreover, the rise of automated air fryer assembly lines has contributed to the industry’s commitment to sustainability. By optimizing production processes and reducing waste, manufacturers are able to minimize their environmental footprint. This has become increasingly important as consumers demand more eco-friendly products.

Looking ahead, the future of air fryer assembly lines is bright. With the integration of artificial intelligence and the Internet of Things (IoT), these lines are set to become even more intelligent and adaptable. Predictive maintenance and real-time data analysis will further enhance production efficiency and product quality.

In conclusion, the rise of automated air fryer assembly lines is a testament to the power of technology in transforming everyday products. It’s a story of innovation that has not only improved the cooking experience for millions but also set the stage for a more efficient and sustainable future in the kitchen appliance industry.

The automated air fryer assembly line is a marvel of modern technology, a testament to how far we’ve come in kitchen appliance manufacturing. These lines are designed to streamline the production process, ensuring that each air fryer that rolls off the line is a precision piece of equipment. Let’s delve into the intricacies of this fascinating system.

In the heart of the automated assembly line, a series of robots and machines work in harmony to transform raw materials into finished products. The process begins with the precise cutting and shaping of the various components that make up an air fryer, including the body, heating elements, and control panels.

One of the standout features of these assembly lines is the precision with which they handle parts. Advanced robotics ensure that each component is positioned correctly and securely fastened, reducing the risk of defects and improving the overall quality of the final product. The use of sensors and cameras helps in monitoring the alignment and fit of each part, guaranteeing a seamless assembly process.

The assembly of the air fryer isn’t just about mechanical precision; it’s also about integrating smart technology. Modern air fryers are equipped with digital interfaces and programmable settings, allowing users to tailor their cooking experiences. During assembly, these features are integrated into the units, with microcontrollers and software being programmed and calibrated to ensure they function flawlessly.

One of the most significant advancements in the automated air fryer assembly line is the use of 3D printing for custom parts. This technology allows for the creation of complex shapes and unique designs that were once impossible to produce. As a result, manufacturers can offer a wider variety of air fryers, catering to different consumer preferences and needs.

As the assembly line moves forward, the components are meticulously assembled. The body of the air fryer is first constructed, with the heating elements being carefully inserted and secured. The exterior is then painted or coated, with the latest in anti-adhesive and heat-resistant materials being applied to ensure durability and efficiency.

The control panel is one of the most sophisticated parts of the assembly process. It involves the precise placement of buttons, displays, and sensors. The integration of these components is done with extreme care, as any error can lead to a malfunctioning unit. The assembly line includes quality checks at each stage, with automated tests verifying the functionality of the control panel.

Once the mechanical and electronic components are in place, the air fryer is subjected to rigorous testing. These tests simulate real-world conditions to ensure that the unit can withstand heat, pressure, and repeated use. The automated testing process is quick and efficient, allowing for a high volume of units to be tested in a short amount of time.

The final stages of the assembly line involve packaging and quality assurance. Each air fryer is carefully packaged, with protective materials used to prevent damage during shipping. Quality checks are conducted one last time to ensure that every unit meets the manufacturer’s high standards.

The automated air fryer assembly line is not just about efficiency; it’s also about sustainability. By reducing the need for manual labor and minimizing waste, these lines help to reduce the environmental impact of production. The use of renewable energy sources and recycling programs further enhance the sustainability of the manufacturing process.

In conclusion, the automated air fryer assembly line is a complex and sophisticated system that brings together cutting-edge technology and precision engineering. It’s a testament to human ingenuity and the relentless pursuit of innovation in the kitchen appliance industry. As technology continues to evolve, we can expect to see even more advanced assembly lines that not only improve the quality of air fryers but also the efficiency and sustainability of their production.

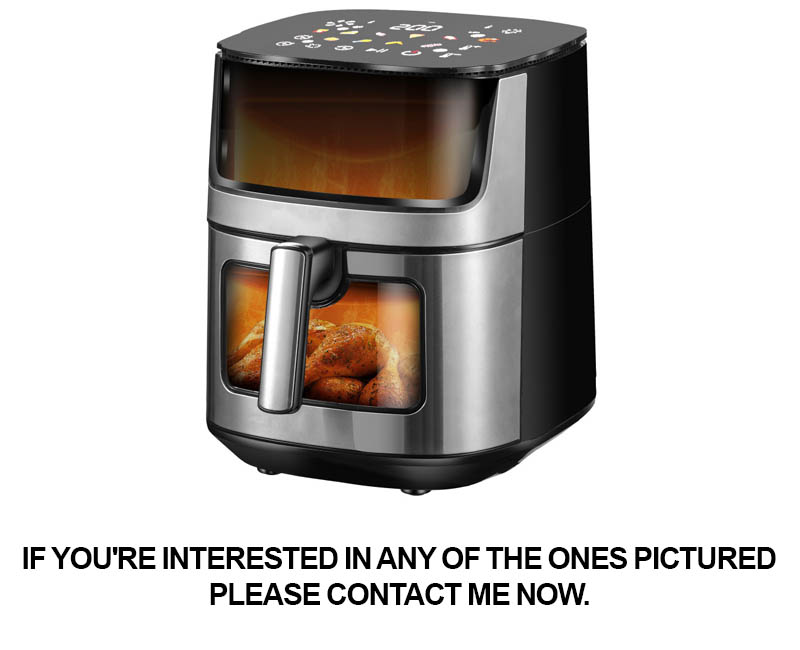

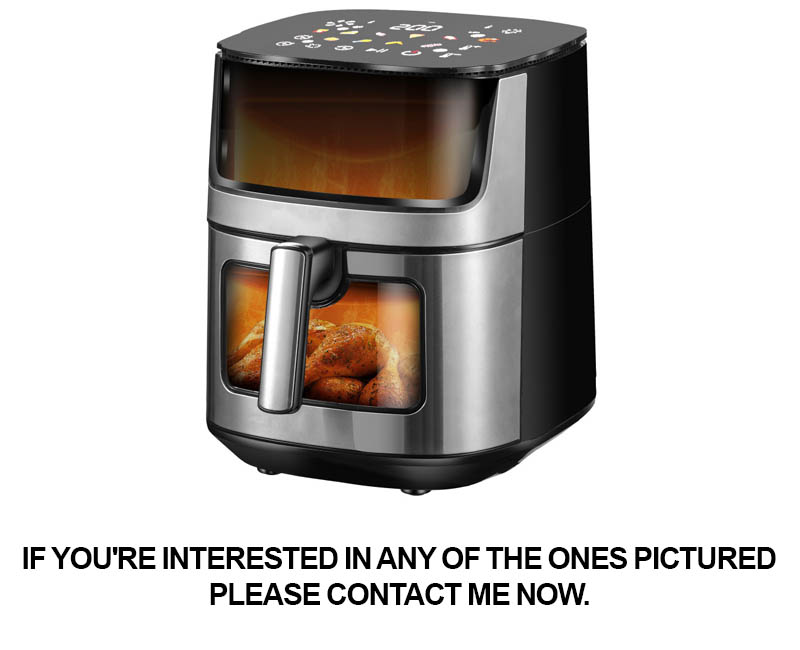

Air fryers have transformed the way we approach cooking, offering a healthier alternative to traditional frying methods. Over the years, these appliances have seen a wave of innovations that not only enhance their functionality but also make them more user-friendly and efficient. Let’s dive into some of the remarkable advancements in air fryer design.

One of the most significant innovations is the integration of smart technology. Modern air fryers are now equipped with digital displays and programmable settings that allow users to control cooking temperatures and times with precision. This not only ensures that food is cooked to perfection but also simplifies the cooking process for even the busiest individuals.

The design of the heating element has also seen considerable improvement. Traditional air fryers used to have a single heating element at the bottom, which often led to uneven cooking. However, newer models now feature multiple heating elements positioned strategically around the drum to ensure consistent heat distribution. This results in uniformly cooked food and eliminates cold spots.

Another innovation is the inclusion of adjustable air flow. This feature allows users to control the intensity of the air circulating around the food, which can be adjusted based on the type of cuisine being prepared. For instance, crispy fried chicken requires a higher airflow to achieve the perfect crunch, while delicate fish might benefit from a gentler setting.

The design of the cooking drum has evolved to accommodate a wider variety of foods. Early models often had smaller capacities and limited space, making it challenging to cook large batches or multiple ingredients at once. Today, many air fryers come with larger drums that can hold more food, making batch cooking a breeze.

Ease of use has been a focal point in recent air fryer designs. Many models now feature non-stick coatings on the interior, which not only make cleaning easier but also reduce the risk of food sticking. The exterior design has also improved, with many brands opting for sleek, modern aesthetics that complement kitchen decor.

One of the standout innovations is the inclusion of a basket that can be used for both air frying and baking. This dual-purpose basket eliminates the need for separate appliances and provides users with more versatility in their cooking options. Whether you’re trying to bake a batch of cookies or fry up some chicken wings, the versatile basket has got you covered.

Many air fryers now come with a variety of preset cooking modes. These modes are tailored to specific types of food, making it even easier to achieve restaurant-quality results at home. For example, there might be a preset for roasting vegetables, grilling steak, or even making French fries, all with a single press of a button.

The control panel has also seen improvements, with many models now offering touch controls instead of traditional dials or buttons. This not only makes the unit look more sophisticated but also adds to the ease of use, allowing users to quickly adjust settings without worrying about dirt or oil getting under the switches.

In terms of energy efficiency, modern air fryers are significantly better than their predecessors. The advanced heating technology means that air fryers use less electricity than traditional ovens, and the ability to cook food at a lower temperature means that less energy is required to reach the desired cooking temperature.

Safety has not been overlooked in the design process. Many air fryers now come with safety features like automatic shut-off when the appliance is left unattended, or if the cooking drum is left open. This not only protects the user from potential accidents but also prevents energy waste.

Finally, the portability of air fryers has been enhanced through the use of compact designs and lightweight materials. This means that users can easily move their air fryer from one place to another, making it perfect for small kitchens or for those who enjoy outdoor cooking.

In conclusion, the design of air fryers has come a long way, offering a plethora of innovations that enhance cooking capabilities, make the appliances more efficient, and improve user experience. These advancements have made air fryers a must-have in modern kitchens, and the future looks promising with even more innovative features on the horizon.

The shift towards automated assembly in the air fryer market has brought about a wave of significant changes that are reshaping the industry. From efficiency gains to cost savings, the impact is multifaceted and profound.

Automated assembly lines have significantly increased production speeds, allowing manufacturers to churn out air fryers at a pace that was once unimaginable. This rapid production capacity has not only met the growing consumer demand but has also positioned companies to scale up quickly in response to market trends and seasonal fluctuations.

The precision of automated systems has led to a marked improvement in product quality. In the past, inconsistencies in assembly could lead to defects or subpar performance of air fryers. Now, with automated processes, each unit is meticulously assembled, ensuring that every air fryer meets stringent quality standards, thus reducing the number of returns and enhancing customer satisfaction.

Cost reductions are a major outcome of automated assembly. By minimizing manual labor and streamlining the production process, manufacturers are able to cut down on labor costs. Additionally, the reduction in errors and waste has a direct impact on the bottom line, as less raw material is used and fewer products are discarded.

The introduction of automated assembly has also led to an increase in product variety. With the ability to produce different models and configurations more efficiently, manufacturers can now cater to a wider range of consumer preferences. This diversity in offerings has expanded the market reach and has allowed companies to tap into niche markets that were previously underserved.

The automation of assembly lines has had a ripple effect on the supply chain. Suppliers have had to adapt to the increased demand for components and parts, leading to a more robust and responsive supply network. This has not only improved the reliability of raw material availability but has also driven innovation in component design, as suppliers vie to provide the best materials for automated assembly.

Consumer expectations have evolved as a result of automated assembly. Customers now expect higher-quality products with advanced features at competitive prices. The ability of manufacturers to meet these expectations has been greatly enhanced by the efficiency and consistency of automated assembly lines.

Safety has also been a major beneficiary of automation. In the past, the manual assembly of air fryers posed significant safety risks to workers, including the risk of repetitive strain injuries and exposure to hazardous materials. Automated assembly lines have significantly reduced these risks, leading to a safer work environment and lower insurance costs for manufacturers.

The environmental impact of air fryer production has also been positively affected by automation. With fewer manual operations, there is a reduction in energy consumption and waste generation. This shift towards sustainability is not only beneficial for the planet but also for the reputation of companies committed to eco-friendly practices.

Lastly, the rise of automated assembly has opened up new opportunities for research and development. Manufacturers can now invest more resources into innovation, exploring new materials, cooking technologies, and user interfaces. This continuous innovation is crucial for staying competitive in a market that is rapidly evolving.

In summary, the market impact of automated assembly in the air fryer industry is undeniable. It has led to faster production, improved quality, cost savings, increased variety, a more robust supply chain, higher consumer expectations, safer work environments, environmental benefits, and a springboard for innovation. These advancements are setting the stage for a new era in kitchen appliance manufacturing.

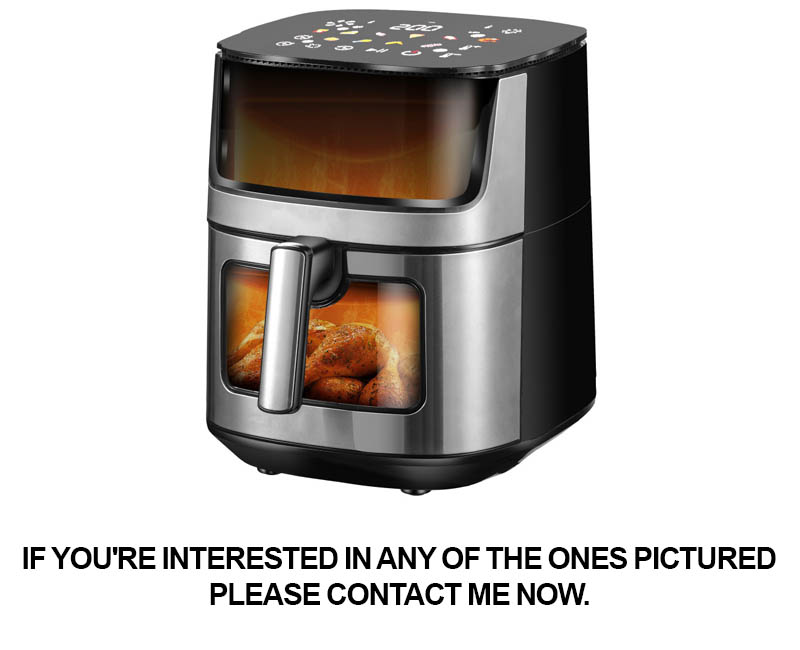

Cooking at home has evolved significantly with the advent of advanced kitchen appliances, and one of the standout benefits for consumers is the surge in innovation that automated assembly lines have brought to air fryer design. Here’s how these advancements are reshaping the consumer experience:

The convenience factor is undeniable. Modern air fryers, thanks to automated assembly, boast user-friendly interfaces that are as simple to operate as a smartphone. These intuitive designs make it easy for even the most technologically averse individuals to enjoy crispy, healthy fried foods with minimal effort.

Energy efficiency has become a cornerstone of modern air fryer design. Automated assembly lines have enabled the integration of cutting-edge insulation materials and energy-saving technologies, resulting in air fryers that use significantly less electricity than traditional deep fryers. Consumers benefit from lower utility bills and a reduced carbon footprint.

The size of air fryers has shrunk without compromising performance. Compact and sleek designs, made possible by the precision of automated assembly, mean that these appliances can easily fit into any kitchen setting, from a small apartment to a bustling household. Consumers gain the freedom to enjoy air frying regardless of their living space.

Health-conscious consumers are flocking to air fryers for their ability to cook food with less oil. Automated assembly has fine-tuned the air frying process, allowing for even distribution of hot air that reduces the need for excess oil. This feature appeals to those looking to maintain a balanced diet while still indulging in their favorite fried treats.

Durability is another significant advantage of air fryers built through automated assembly. The precision and consistency of the assembly process result in appliances that are more resistant to wear and tear, promising a longer lifespan than their predecessors. Consumers get more value from their purchases as they don’t have to replace their air fryers as frequently.

Customization has become a hallmark of modern air fryer design. Automated assembly lines can easily accommodate various sizes and configurations, allowing manufacturers to introduce a wide array of models that cater to different cooking preferences and needs. From single-serve units to large-capacity models suitable for entertaining, consumers have a plethora of options to choose from.

Safety features have been bolstered thanks to the automation process. Air fryers now come with smart functions like automatic shut-off and overheat protection, all of which are integrated seamlessly through automated assembly. Consumers can enjoy peace of mind knowing that their kitchen appliances are equipped to prevent accidents.

Cooking times have been drastically reduced. The precise control and efficient heat distribution in air fryers allow for faster cooking compared to conventional cooking methods. This not only saves time but also preserves the nutritional value of food, as there is less opportunity for vitamins and minerals to degrade.

With automated assembly, air fryers are more consistent in their performance. The repetitive nature of the assembly line ensures that every unit is built to the same high standard, eliminating the variability that often comes with handmade or manually assembled appliances. Consumers can expect a consistent experience with each use.

Lastly, the cost of ownership has been improved. Thanks to increased production efficiency and reduced waste during automated assembly, air fryers are more affordable than ever. Consumers can now enjoy the benefits of air frying without breaking the bank.

In summary, the benefits for consumers in the wake of automated air fryer assembly are numerous, from convenience and health to cost savings and environmental impact. These innovations continue to drive the popularity of air fryers and enhance the culinary experiences of those who choose to cook with them.

Navigating the complexities of automation in various industries, the kitchen appliance sector is no exception. The transition from manual to automated assembly lines for air fryers, for instance, has brought about a wave of challenges that must be addressed. Here’s a closer look at some of these challenges and the innovative solutions that are making a difference.

Maintaining Precision and Quality ControlOne of the primary challenges in automating the assembly of air fryers is ensuring that each unit maintains the same level of precision and quality. Human error can be minimized with automation, but it also demands meticulous programming and constant monitoring to prevent defects. Solutions include the use of advanced sensors and vision systems that can detect and correct issues in real-time, ensuring that every air fryer that rolls off the line meets the highest standards.

Dealing with Technological LimitationsAutomation isn’t just about replacing human labor; it’s about integrating technology that can handle the intricacies of assembly. However, not all parts of the process can be fully automated due to technological limitations. To overcome this, manufacturers are investing in research and development to create more sophisticated machinery. Collaborations with tech companies are also common, as they bring expertise in robotics and AI to the table.

Training and Transitioning WorkforcesThe shift to automation requires a skilled workforce that can operate and maintain the new machinery. This transition can be challenging, as it often necessitates retraining employees or hiring new talent with specialized skills. To address this, companies are implementing comprehensive training programs and investing in educational partnerships to ensure their workforce is ready for the automated era. Additionally, some are adopting a hybrid model that combines automated processes with tasks that require human intuition and creativity.

Supply Chain ManagementAutomated assembly lines demand a highly efficient supply chain to ensure a steady flow of parts and materials. The challenge lies in managing inventory levels, minimizing lead times, and avoiding disruptions. Solutions include the use of advanced inventory management systems that predict demand and optimize stock levels, as well as the implementation of just-in-time (JIT) delivery systems to reduce waste and improve efficiency.

Adapting to Changing RegulationsRegulatory requirements can vary by region and are often subject to change. Ensuring compliance with these regulations while maintaining an automated assembly line can be a daunting task. Companies are staying ahead by employing compliance experts who stay informed about the latest regulations and work closely with legal teams to ensure that every aspect of the assembly process adheres to the necessary standards.

Overcoming Space ConstraintsAutomated assembly lines require significant floor space, which can be a challenge in facilities with limited space. To tackle this, manufacturers are looking into vertical integration and space-saving designs. The use of multi-level assembly systems and modular components that can be reconfigured as needed allows for more efficient use of space without compromising on productivity.

Handling Variability in ProductionThe kitchen appliance market is known for its variety, with different models and features catering to diverse consumer needs. Automating the assembly of these varied products can be challenging due to the need for flexibility. Solution providers are developing adaptive systems that can switch between different product configurations quickly and efficiently, reducing downtime and increasing throughput.

Addressing Energy ConsumptionAutomation often comes with increased energy consumption, which can be a significant cost and environmental concern. To combat this, manufacturers are investing in energy-efficient machinery and integrating renewable energy sources into their operations. By optimizing energy use and reducing waste, they aim to minimize their carbon footprint while keeping operational costs in check.

In conclusion, the challenges of automation in the air fryer assembly line are multifaceted, but so are the solutions. From technological innovations to workforce training and sustainable practices, the industry is continuously evolving to meet the demands of a modern, efficient, and compliant production environment.

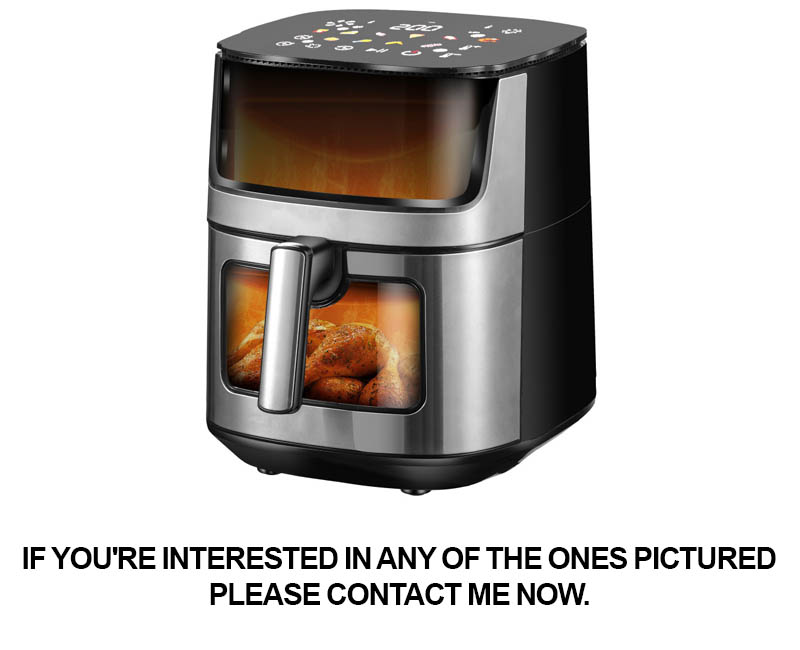

The integration of advanced robotics and AI into the assembly process promises not only increased efficiency but also a new level of precision. These technologies can adapt to various models and sizes of air fryers, ensuring that each unit meets the highest quality standards. The result is a streamlined production line that can handle complex designs with ease.

Smart sensors and real-time data analytics are becoming integral parts of automated assembly lines. They provide manufacturers with the ability to monitor and optimize the production process in real-time, detecting issues before they become significant problems. This proactive approach not only reduces downtime but also ensures that the end product is consistently high quality.

As the demand for healthier cooking options grows, so does the need for air fryers that can cater to a wide range of dietary preferences. The future of automated assembly will likely see an increase in customizable features, such as adjustable temperature controls and various cooking modes. This will allow consumers to tailor their air fryers to their specific needs, whether they’re following a keto diet or simply looking to reduce oil usage.

The rise of 3D printing technology is another trend that could reshape the automated assembly of air fryers. This technology allows for the creation of complex parts with intricate designs that were previously impossible to produce using traditional methods. It opens up possibilities for personalized air fryers, where consumers can choose from a variety of unique designs and features.

Energy efficiency is a critical concern in today’s world, and the future of automated air fryer assembly will likely focus on sustainable practices. This could include the use of renewable energy sources in the manufacturing process, as well as the development of air fryers that consume less power while still maintaining high performance. The goal is to create a product that not only benefits the consumer but also has a minimal environmental impact.

The advent of the Internet of Things (IoT) will also play a significant role in the future of automated assembly. Air fryers could be equipped with IoT capabilities, allowing them to connect to other kitchen appliances and even to the consumer’s smartphone. This connectivity would enable features such as remote control, automated meal planning, and predictive maintenance, enhancing the user experience and potentially reducing maintenance costs.

Customization and personalization are not just about design; they extend to the materials used in the air fryer’s construction. The future may see a shift towards using recycled and sustainable materials, not only to reduce waste but also to appeal to environmentally conscious consumers. This could include biodegradable plastics, recycled metals, and other eco-friendly components.

The industry is also likely to see an increase in collaborative robots, or cobots, which work alongside human workers. Cobots are designed to assist with repetitive tasks, reducing the risk of injury and allowing human workers to focus on more complex and creative aspects of the manufacturing process. This synergy between human and machine could lead to more innovative designs and a more efficient production line.

Lastly, the future of automated air fryer assembly will be driven by a commitment to continuous improvement. Manufacturers will be encouraged to invest in research and development to find new ways to enhance the assembly process, from the design of the air fryers themselves to the systems that power the assembly lines. This relentless pursuit of innovation will ensure that the air fryers of tomorrow are not just better than those of today, but also more adaptable to the changing needs of consumers and the marketplace.

In the world of automated air fryer assembly, there are several case studies and success stories that showcase the effectiveness and innovation of this technology. From small startups to global giants, these examples highlight the benefits of automation in the kitchen appliances industry.

One such success story comes from a mid-sized appliance manufacturer that transitioned from a traditional assembly line to an automated one. The company found that their production process was plagued by inefficiencies and high defect rates. By implementing an automated air fryer assembly line, they were able to drastically reduce their error rates, decrease production time, and improve overall quality. This, in turn, allowed them to increase their market share and customer satisfaction.

Another notable case is that of a well-known global brand that decided to invest in an automated assembly line for their air fryers. The brand was facing increased competition from budget-friendly options, and they needed a way to maintain their reputation for quality and innovation. By automating their assembly process, they were able to produce air fryers that were not only more consistent in quality but also at a lower cost. This enabled them to offer competitive pricing while still providing a premium product.

In one particularly impressive example, a startup that focused on eco-friendly kitchen appliances introduced an automated assembly line for their air fryers. The company’s mission was to reduce waste and energy consumption in the production process. By using an automated system, they were able to minimize manual handling, which decreased the risk of damage to the appliances and reduced the need for packaging materials. This approach not only helped the startup stand out in a crowded market but also attracted environmentally conscious consumers.

These case studies and success stories demonstrate several key points about the impact of automation in air fryer assembly:

Quality Control: Automated assembly lines can significantly improve the quality of products by reducing the potential for human error. This is crucial in the air fryer industry, where safety and performance are paramount.

Cost Efficiency: While the initial investment in automation can be substantial, the long-term savings often outweigh the costs. Reduced waste, lower labor expenses, and increased production rates all contribute to a more cost-effective manufacturing process.

Innovation: Automation opens the door to new design possibilities and features. Companies can experiment with materials, shapes, and functions, leading to innovative products that can attract new customers.

Market Adaptability: As consumer demands change, automated assembly lines can be more easily modified to meet new standards and requirements. This agility allows manufacturers to stay competitive and responsive to market shifts.

Environmental Impact: Automation can also have a positive environmental impact by reducing energy consumption, waste, and emissions. This is especially important for companies looking to differentiate themselves as eco-friendly brands.

In conclusion, the case studies and success stories of companies that have embraced automation in air fryer assembly illustrate the transformative power of this technology. Whether it’s improving quality, cutting costs, fostering innovation, or reducing environmental impact, automation is a key driver of progress in the kitchen appliances sector.

In the realm of manufacturing, the environmental angle has become a pivotal consideration, especially in the production of kitchen appliances like air fryers. As the world grapples with climate change and the need for sustainable practices, the impact of these devices on the environment is under closer scrutiny. Here’s a look at how the environmental angle is shaping the landscape of air fryer assembly and manufacturing.

The Shift Towards Eco-Friendly MaterialsManufacturers are increasingly focusing on using sustainable and eco-friendly materials in the production of air fryers. This includes biodegradable plastics, recycled metals, and energy-efficient components. The adoption of these materials not only reduces the carbon footprint but also ensures that the end product is more environmentally conscious.

Energy Efficiency in Assembly ProcessesThe assembly lines themselves are being overhauled to be more energy-efficient. Advanced technologies are being employed to minimize energy consumption during the manufacturing process. This includes the use of LED lighting, automated systems that reduce idle time, and smart energy management systems that optimize power usage.

Reducing Waste in ProductionWaste reduction is a key environmental concern in the air fryer assembly process. Companies are implementing lean manufacturing principles to minimize scrap and by-products. This involves precise planning, efficient material handling, and the use of just-in-time inventory systems to reduce waste.

Water Conservation EffortsWater is a precious resource, and conservation is crucial in the manufacturing sector. Air fryer assembly lines are now equipped with water-saving technologies and processes. Recirculating water systems, efficient cooling towers, and the reduction of water-intensive cleaning procedures are all part of the strategy to conserve this vital resource.

Carbon Footprint Tracking and ReductionManufacturers are taking a proactive approach to tracking and reducing the carbon footprint of their products. This involves calculating the entire lifecycle of the air fryer, from raw material extraction to disposal. By identifying the most significant contributors to carbon emissions, companies can implement targeted strategies to mitigate their impact.

Sustainable Packaging SolutionsThe packaging of air fryers is another area where environmental considerations are paramount. Companies are exploring alternative packaging materials that are recyclable, biodegradable, or made from renewable resources. Moreover, the design of packaging is being optimized to reduce material usage and ensure that it is easily recyclable or compostable.

Consumer Education on SustainabilityEducating consumers about the environmental benefits of air fryers is also a crucial aspect. Manufacturers are incorporating sustainability messaging into their marketing and product information. This helps consumers make informed choices and encourages them to support eco-friendly products.

Certifications and StandardsMany manufacturers are seeking certifications and adhering to international standards that promote environmental responsibility. This includes certifications like Energy Star for energy efficiency and the EU Ecolabel for environmental performance. These certifications serve as a trust signal to consumers that the product meets high environmental standards.

Collaboration with Environmental OrganizationsTo stay ahead of environmental regulations and trends, manufacturers are collaborating with environmental organizations. These partnerships provide insights into emerging issues and help in developing innovative solutions that are both sustainable and compliant with global environmental laws.

The Future of Environmental ResponsibilityLooking ahead, the environmental angle in air fryer assembly is poised to become even more integral to the industry. As technology advances and consumer awareness grows, we can expect to see even more innovative and sustainable practices being adopted. The future of air fryer assembly will likely be defined by a relentless pursuit of environmental excellence.

In the ever-evolving landscape of technology and consumer demand, the journey of innovation in the automated air fryer assembly line has been marked by significant strides. The industry has witnessed a transformation that not only enhances productivity but also reshapes the way we perceive kitchen appliances. As we reflect on the impact of these advancements, several key points emerge, highlighting the profound influence on various aspects of our lives.

The integration of smart technology and automation in air fryer assembly has led to a surge in efficiency and precision. This has translated into faster production times without compromising on quality, a crucial factor in the competitive market. The seamless integration of robotics and AI has allowed for the creation of more sophisticated and user-friendly appliances, catering to the diverse needs of consumers.

Moreover, the shift towards sustainability has become a cornerstone in the industry. Manufacturers are increasingly focusing on eco-friendly practices, from the sourcing of materials to the reduction of waste in the production process. This not only appeals to environmentally conscious consumers but also aligns with global efforts to combat climate change.

The rise of the automated air fryer assembly line has also had a significant impact on the workforce. While there are concerns about job displacement, the reality is that these advancements have created new roles and opportunities. Workers are now able to focus on tasks that require human creativity and oversight, leading to a more dynamic and skilled workforce.

On the consumer front, the benefits are manifold. The affordability and accessibility of air fryers have skyrocketed, making healthier cooking options more attainable for a wider audience. The convenience and versatility of these appliances have changed the way we approach meal preparation, encouraging healthier eating habits without the need for extensive cooking skills.

However, challenges persist. The complexity of these automated systems requires continuous maintenance and skilled technicians to keep them running smoothly. Additionally, the initial investment for such technology can be substantial, which may be a barrier for some smaller manufacturers.

Looking ahead, the future of automated air fryer assembly is bright but not without its share of uncertainties. Innovations in materials science, such as the development of more durable and energy-efficient components, will likely drive the next wave of improvements. The integration of augmented reality and virtual reality in design and assembly processes could further refine the precision and efficiency of the manufacturing process.

Collaboration between technology providers, manufacturers, and regulatory bodies will be crucial in addressing the regulatory challenges that come with such advanced technology. Ensuring that these systems are safe, reliable, and accessible to all consumers is a priority.

As we stand at the precipice of what might be the next industrial revolution, it’s clear that the automated air fryer assembly line is not just a trend; it’s a catalyst for change. It has the power to redefine the kitchen, improve health outcomes, and contribute to a more sustainable future. The journey from manual to automated assembly has been a testament to human ingenuity and our relentless pursuit of progress. While there are hurdles to overcome, the potential rewards are vast, and the path forward is one of continuous innovation and adaptation.