Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

In the ever-evolving world of kitchen appliances, the commercial air fryer has emerged as a revolutionary product, transforming the way we cook and consume food. This surge in popularity isn’t just a fleeting trend; it’s a testament to the relentless pursuit of healthier and more efficient culinary solutions. As we delve into the nuances of the commercial air fryer market, it becomes clear that the factors driving its growth are multifaceted, from technological advancements to the changing demands of consumers. Join us as we explore the impact of industry trends on manufacturing, navigate the competitive landscape, and understand the critical role of quality control and safety in this burgeoning sector. We’ll also uncover how data and analytics are shaping product development and the significance of sustainability and energy efficiency in air fryer production. By the end, we’ll reflect on the future of commercial air fryer factories and the path they are paving for the next generation of kitchen appliances.

The commercial air fryer market has experienced a remarkable surge in popularity over recent years, becoming a staple in both professional kitchens and homes across the globe. These versatile appliances have revolutionized the way we cook, offering a healthier alternative to traditional frying methods. In this dynamic industry, understanding the intricacies of the market is crucial for those looking to dive into the world of commercial air fryer manufacturing.

Commercial air fryers are designed to mimic the frying process using hot air circulation, significantly reducing the amount of oil needed while still delivering crispy, delicious results. This technology has caught the attention of health-conscious consumers and chefs alike, as it allows for the preparation of fried foods with fewer calories and less fat.

One of the key drivers behind the market’s growth is the increasing awareness of health and wellness. As people become more conscious of their dietary habits, they are seeking out cooking methods that offer healthier alternatives without compromising on taste. This shift has propelled the demand for air fryers, especially in the commercial sector, where efficiency and health benefits are paramount.

The commercial air fryer market is also being fueled by the convenience it offers. These appliances can quickly cook a variety of foods, from crispy fries to succulent chicken, all while saving time and energy. This efficiency is particularly appealing to busy restaurants, cafes, and foodservice operations that need to serve large volumes of food with minimal wait times.

Another factor contributing to the market’s growth is the innovation in technology. Manufacturers are constantly pushing the boundaries, introducing features like programmable settings, temperature control, and even smart connectivity. These advancements not only enhance the cooking experience but also make the appliances more accessible and user-friendly for commercial operators.

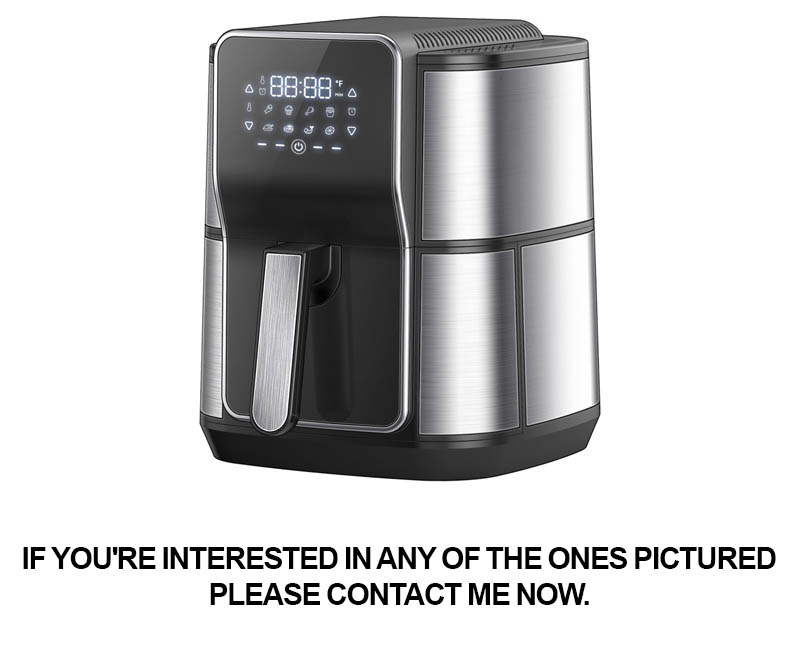

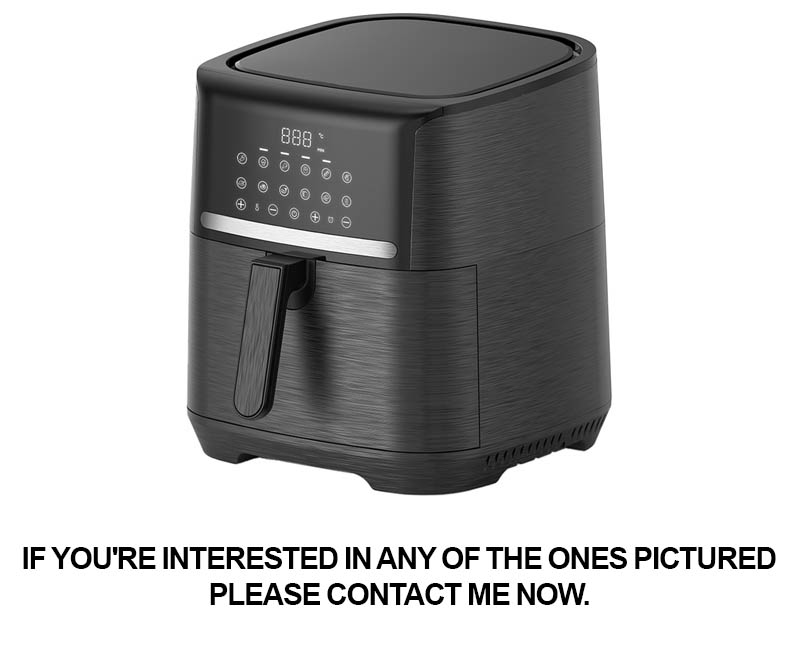

Within the commercial air fryer market, there is a diverse range of products catering to different needs. From countertop models that are perfect for small restaurants and cafes to larger, industrial-sized units suitable for busy fast-food chains and catering services, the variety is vast. This diversity allows businesses to choose the right air fryer that fits their specific requirements and operational scale.

The competitive landscape of the commercial air fryer market is quite dynamic, with numerous players vying for a share of the growing pie. Established appliance brands are expanding their product lines to include air fryers, while new entrants are bringing fresh ideas and innovative designs to the table. This competition has led to a constant stream of new features and improvements, keeping the market fresh and exciting.

In terms of distribution, commercial air fryers are typically sold through a network of distributors, retailers, and direct to businesses. The market is also seeing an increase in online sales, with more manufacturers and retailers offering direct-to-consumer purchases through e-commerce platforms. This digital shift has made it easier for businesses to access a wider range of products and compare prices and features without leaving their establishment.

Quality control and safety are non-negotiable in the commercial air fryer market. Manufacturers must adhere to strict standards to ensure that their products are reliable and safe for use in professional settings. This includes rigorous testing for durability, performance, and compliance with safety regulations. The trust that consumers and businesses place in these appliances is a testament to the industry’s commitment to excellence.

The role of data and analytics in the commercial air fryer market cannot be overstated. By analyzing consumer trends, usage patterns, and feedback, manufacturers can better understand the market’s needs and develop products that truly resonate with customers. This data-driven approach is also crucial for optimizing production processes and reducing costs.

In recent years, sustainability has become a major concern for businesses worldwide. The commercial air fryer market is responding to this trend by focusing on energy efficiency and environmentally friendly materials. By producing air fryers that consume less energy and are made from recyclable or biodegradable materials, manufacturers are not only appealing to eco-conscious consumers but also reducing their carbon footprint.

As the commercial air fryer market continues to evolve, it’s clear that innovation, health consciousness, and sustainability will remain key drivers. The future holds exciting possibilities, with advancements in technology likely to further transform the way we cook and eat. For those involved in manufacturing, staying ahead of these trends and meeting the demands of a health-conscious, tech-savvy consumer base will be essential for success.

The air fryer, once a niche appliance, has surged to the forefront of kitchen technology, revolutionizing the way we cook and eat. With its promise of crispy, healthy fried foods with significantly less oil, it’s no wonder this kitchen gadget has captured the hearts and minds of home chefs and culinary enthusiasts alike. Let’s delve into the meteoric rise of the air fryer and its impact on our culinary habits.

Gone are the days when frying was synonymous with indulgence and high fat content. The air fryer’s innovation lies in its ability to circulate hot air around food, mimicking the deep-frying process but with a fraction of the oil. This technology has not only transformed the health profile of fried dishes but has also introduced a new wave of culinary possibilities.

Culinary experts have embraced the air fryer for its versatility, which extends beyond traditional fried foods. From crispy chicken wings to tender roasted vegetables, the air fryer’s even heat distribution ensures that food is cooked to perfection. It’s not just a frying appliance; it’s a multipurpose kitchen tool that has become a staple in modern kitchens.

As the awareness of health and wellness has grown, so has the demand for healthier cooking methods. The air fryer taps into this trend by offering a guilt-free alternative to deep-frying. Its ability to cook food with up to 80% less oil has made it a favorite among health-conscious consumers, fitness enthusiasts, and even chefs looking to create lighter, more balanced dishes.

The convenience factor of the air fryer cannot be overstated. Its compact design and ease of use make it an ideal kitchen companion. With a simple setup and minimal cleanup, the air fryer has become a go-to for those with busy lifestyles or those who prefer quick and efficient cooking methods. It’s not uncommon to see air fryers on the countertops of busy professionals, parents, and students.

Retail sales have soared as manufacturers have caught on to the air fryer’s potential. From small startups to established appliance brands, there’s a proliferation of air fryer models available in various shapes, sizes, and price points. This variety caters to different consumer preferences and budgets, ensuring that the air fryer market continues to expand.

The rise of social media and cooking blogs has also played a significant role in popularizing the air fryer. Influencers and home cooks have taken to platforms like Instagram, YouTube, and Pinterest to showcase their air fryer creations, from homemade snacks to gourmet meals. This digital exposure has sparked a sense of curiosity and excitement around the appliance, driving more consumers to consider purchasing one.

Furthermore, the air fryer has bridged the gap between homemade and fast-food experiences. Many people enjoy the taste and satisfaction of homemade food but are reluctant to invest the time or the calories in cooking it. The air fryer offers a compromise, allowing for quick, homemade versions of their favorite fried treats with a fraction of the fat.

As the air fryer continues to gain popularity, it’s also inspiring innovation within the industry. We’re seeing a surge in smart air fryers that can be controlled remotely via smartphones, offering users the ability to monitor and adjust cooking settings on the go. Some models even come with pre-programmed recipes and cooking times, making it even easier for the busy consumer to enjoy restaurant-quality meals at home.

In conclusion, the air fryer’s rise to culinary prominence is a testament to the evolving demands of the modern consumer. It’s a versatile, healthy, and convenient appliance that has become a game-changer in the kitchen. With its continued innovation and growing market presence, it’s clear that the air fryer isn’t just a fleeting trend but a permanent fixture in the world of kitchen appliances.

The surge in popularity of air fryers has been nothing short of remarkable. These compact kitchen gadgets have quietly transformed the way we approach cooking, offering a healthier alternative to traditional frying methods. To grasp the demand driving this growth, we need to look at several key factors.

Health and Wellness Trend: The growing health consciousness among consumers has been a significant driver of air fryer demand. With the rise of fast-food culture and the increased awareness of the negative health impacts of deep-frying, air fryers provide a solution that allows for the enjoyment of fried foods with a fraction of the oil. Their ability to offer crispy, golden-brown results with less fat has resonated with health-savvy consumers.

Technological Advancements: The evolution of air fryer technology has played a crucial role in their market success. Early models were often bulky and less efficient, but modern air fryers are sleek, compact, and feature advanced heating systems that circulate hot air around the food, mimicking the frying process but with far less oil. These improvements have made air fryers more appealing and practical for everyday use.

Ease of Use: One of the main reasons for the surge in air fryer sales is the ease of use. These appliances require minimal prep time and often come with simple-to-follow recipes. Their intuitive interfaces and automatic settings mean that even those who are not confident in the kitchen can enjoy deliciously fried foods with minimal effort. The convenience factor has been a major draw for busy consumers and families alike.

Cooking Versatility: Air fryers have expanded their culinary repertoire beyond the realm of fried foods. Many models now offer a range of cooking functions, from roasting to baking and even defrosting. This versatility means that users can prepare a wide variety of dishes, from crispy French fries to tender chicken breasts, all in one appliance. This adaptability has broadened the appeal of air fryers and made them a staple in many kitchens.

Cost-Effectiveness: Air fryers are generally more affordable than traditional deep fryers, which is a significant factor in their popularity. Their lower cost of ownership, combined with the long-term health benefits, makes them an attractive purchase for budget-conscious consumers. The fact that they can also replace other kitchen appliances like an oven or a toaster oven further enhances their value proposition.

Marketing and Branding: Smart marketing strategies and strong branding have also contributed to the growth in air fryer demand. Companies have leveraged social media, influencer partnerships, and cooking shows to showcase the ease and health benefits of air fryers. The association of these appliances with a healthier lifestyle and the joy of cooking has made them a must-have item for many consumers.

Sustainability and Environmental Concerns: In recent years, sustainability has become a major concern for consumers. Air fryers are often marketed as eco-friendly due to their reduced energy consumption and the fact that they use less oil than traditional frying methods. This appeal to environmental consciousness has helped to drive demand, especially among eco-conscious consumers and those living in urban areas where energy efficiency is a priority.

Economic Factors: The global economic landscape has also played a role in the growth of the air fryer market. As disposable incomes rise, particularly in emerging markets, consumers have more money to spend on kitchen appliances that enhance their quality of life. Air fryers have become a popular addition to the kitchen arsenal, as they offer a blend of health, convenience, and enjoyment at a reasonable price point.

In summary, the demand for air fryers is driven by a combination of health trends, technological advancements, ease of use, cooking versatility, cost-effectiveness, effective marketing, sustainability concerns, and economic factors. These elements have come together to create a perfect storm of popularity, propelling air fryers into the forefront of kitchen appliances worldwide.

The commercial air fryer market has witnessed a surge in popularity, driven by a combination of technological advancements, consumer preferences, and health-conscious trends. Here’s a look at some of the key innovations shaping the technology behind these kitchen game-changers.

Enhanced Capacity and DesignCommercial air fryers have evolved from compact units to larger, industrial-sized appliances that can cater to high-volume demands in restaurants, hotels, and catering services. These units often feature sleek designs and durable materials, ensuring they can withstand the rigors of commercial use while maintaining a modern aesthetic.

Advanced Heat DistributionOne of the most significant innovations in commercial air fryer technology is the improvement in heat distribution. Early models often struggled with hotspots, leading to uneven cooking. Modern fryers utilize advanced fan systems and heating elements to ensure consistent temperatures throughout the basket, resulting in perfectly crispy and golden fried foods every time.

Smart Temperature ControlModern commercial air fryers come equipped with precise temperature control systems that allow chefs and operators to fine-tune the cooking process. With digital displays and adjustable settings, these fryers can accommodate a wide range of recipes, from delicate French fries to hearty chicken wings, all with minimal risk of burning or overcooking.

Energy EfficiencyEnergy efficiency has become a cornerstone of innovation in the commercial air fryer industry. Newer models are designed to consume less electricity while maintaining high cooking performance. This not only reduces operational costs but also aligns with the growing demand for sustainable and eco-friendly kitchen appliances.

Integrated Filtration SystemsTo address concerns about oil usage and health, many commercial air fryers now come with integrated filtration systems. These systems help trap and remove excess oil from the food, resulting in healthier fried foods with less fat. Some models even have self-cleaning filters, reducing maintenance time and effort.

Versatile Cooking ModesCommercial air fryers are no longer limited to just frying. Advanced models offer a variety of cooking modes, including roasting, baking, and grilling. This versatility allows businesses to offer a wider range of menu options without the need for multiple appliances.

User-Friendly FeaturesThe user interface of commercial air fryers has seen significant improvements, with many now featuring intuitive controls and programmable settings. This makes it easier for staff to operate the fryers without extensive training, leading to increased efficiency and reduced downtime.

Enhanced Safety FeaturesSafety is a top priority in the commercial kitchen, and air fryers have been fitted with various safety features to prevent accidents. These include automatic shut-offs in case of overheating, child locks to prevent unauthorized use, and non-slip bases to ensure stability during operation.

Customizable and Modular DesignsManufacturers are now offering customizable and modular designs for commercial air fryers. This allows businesses to tailor the fryers to their specific needs, whether it’s adjusting the size of the cooking basket or integrating the fryer into a larger kitchen setup.

Integration with Smart Kitchen SystemsThe integration of commercial air fryers with smart kitchen systems is another innovation on the horizon. This would allow for remote monitoring and control, data analytics for inventory and usage tracking, and even predictive maintenance to prevent equipment breakdowns.

As the commercial air fryer market continues to grow, innovation will be key to meeting the diverse needs of operators and consumers alike. From capacity and design to technology and safety, these innovations are not only improving the efficiency of commercial kitchens but also setting the stage for a healthier and more sustainable foodservice industry.

The commercial air fryer market has seen a remarkable surge in popularity, transforming the way kitchens operate across the globe. This shift is not just a passing trend but a testament to the evolving demands and expectations of consumers. To delve into the reasons behind this demand, several key factors have emerged as pivotal drivers of growth.

Health and Wellness AwarenessThe increasing health consciousness among consumers has led to a greater demand for healthier cooking methods. Air fryers offer a healthier alternative to traditional frying, reducing the amount of oil used by up to 80%. This feature has resonated with health-conscious consumers who are looking for ways to enjoy their favorite fried foods without the guilt.

Convenience and EfficiencyModern lifestyles are fast-paced, and convenience is a top priority. Commercial air fryers provide a quick and efficient way to cook a variety of foods. With settings that cater to different types of cooking, such as crispy chicken, roasted vegetables, or even desserts, these appliances save time and effort, making them a favorite among busy professionals and restaurant owners.

Versatility in Cooking OptionsThe versatility of air fryers is a game-changer in the kitchen. These appliances can replace a range of cooking methods, from baking to grilling to dehydrating. This one-appliance-can-do-it-all approach is highly appealing to consumers who are looking to streamline their kitchen equipment and reduce clutter.

Cost-EffectivenessDespite the premium features and technology, commercial air fryers are often more cost-effective than traditional deep fryers. They require less oil, which not only saves money on cooking oil but also reduces waste. Additionally, the energy-efficient nature of air fryers translates to lower utility bills, making them an economical choice for both consumers and businesses.

Technological AdvancementsThe technology behind air fryers has seen significant advancements, contributing to their growing popularity. Features like digital controls, programmable settings, and even Wi-Fi connectivity allow users to monitor and control their cooking remotely. These innovations enhance the user experience and make air fryers more accessible to a wider audience.

Market Trends and Consumer BehaviorMarket trends play a crucial role in shaping the demand for commercial air fryers. The rise of social media and influencer marketing has brought these appliances into the spotlight, with many consumers seeking out the latest kitchen gadgets. The trend towards healthier eating and the desire for convenience align perfectly with the capabilities of air fryers.

Environmental ConcernsAs the world becomes more environmentally conscious, the impact of appliances on the environment is a significant consideration. Air fryers are a greener alternative to deep fryers due to their lower energy consumption and reduced oil usage. This eco-friendly aspect is attracting environmentally conscious consumers and businesses alike.

Culinary ExplorationThe ability to experiment with a wide range of recipes is another factor driving the demand for commercial air fryers. Chefs and home cooks are excited by the possibilities these appliances offer, from creating crispy French fries to air-fried doughnuts. The culinary community’s embrace of air fryers has helped to popularize the technology among a broader audience.

Retail and Distribution ChannelsThe expansion of retail and distribution channels has also played a role in the growth of the commercial air fryer market. As these appliances become more readily available in stores and online, consumers have easier access to them, further fueling demand.

Industry CollaborationFinally, the collaboration between appliance manufacturers and foodservice providers has been instrumental in the adoption of air fryers in commercial settings. By working together to develop specialized models for restaurants and catering services, the industry has been able to meet the unique needs of commercial kitchens.

The impact of these factors on the manufacturing of commercial air fryers is profound. Manufacturers must stay attuned to these trends and consumer demands to produce appliances that not only meet but exceed expectations. The dynamic nature of the market requires continuous innovation and adaptation, ensuring that the commercial air fryer remains a staple in kitchens around the world.

In today’s fast-paced culinary world, the competitive landscape for commercial air fryer manufacturers is both challenging and exciting. Understanding the dynamics at play is crucial for navigating this market effectively. Here’s a closer look at the competitive environment:

The market is marked by a diverse array of players, each bringing their unique strengths and offerings to the table. From established appliance giants to niche startups, the competition spans across various price points and technological advancements.

Brands that have been in the industry for years often have a loyal customer base and a robust distribution network. They leverage their brand recognition and customer trust to stay ahead. However, they must also adapt to changing consumer preferences and market demands.

On the other hand, newer entrants are often more agile and willing to experiment with new features and technologies. They may not have the same level of brand equity, but they can gain traction by offering innovative solutions at competitive prices.

One key factor in the competitive landscape is the emphasis on health and wellness. As consumers become more health-conscious, they’re seeking cooking methods that allow them to enjoy their favorite foods with fewer calories and less oil. This has spurred a race among manufacturers to develop air fryers that are not only efficient but also provide healthier cooking options.

Energy efficiency is another area of competition. With rising energy costs and a growing environmental awareness, manufacturers are focusing on creating air fryers that consume less power while maintaining the same cooking performance. This not only appeals to environmentally conscious consumers but also to those looking to save on their utility bills.

Customization is also a key differentiator. Many companies are offering air fryers with a range of features, such as adjustable temperature settings, timers, and even Bluetooth connectivity for remote monitoring. These added functionalities can set a brand apart from its competitors, particularly in the B2B sector where commercial kitchens demand versatility and control.

Innovation in materials is another area where manufacturers are striving to gain an edge. Lightweight, durable, and easy-to-clean materials are in high demand. Brands that can produce air fryers that are not only functional but also aesthetically pleasing and easy to maintain are more likely to capture the interest of both consumers and businesses.

The importance of sustainability cannot be overstated. As consumers and businesses alike seek out eco-friendly products, manufacturers are under pressure to adopt green practices in their production processes. This includes using recyclable materials, reducing waste, and minimizing carbon footprints. Those that can demonstrate a commitment to sustainability are likely to build a loyal customer base.

The role of marketing and distribution cannot be ignored either. In a crowded market, brands need to find effective ways to stand out. This involves everything from targeted advertising campaigns to strategic partnerships with key retailers and online platforms. Social media has become a powerful tool for reaching potential customers, and companies that use it wisely can significantly boost their visibility and sales.

Lastly, the rise of e-commerce has reshaped the competitive landscape. Online sales platforms have democratized access to a global market, allowing smaller players to compete with larger manufacturers. However, this also means that the market is more saturated and customer service and after-sales support have become crucial differentiators.

In summary, navigating the competitive landscape of commercial air fryer manufacturing requires a multi-faceted approach. It involves staying abreast of consumer trends, focusing on innovation, maintaining high standards of quality and sustainability, and leveraging effective marketing and distribution strategies. Only those companies that can successfully balance these elements will be able to thrive in this dynamic and evolving market.

In the fast-paced world of commercial air fryer manufacturing, maintaining stringent quality control and adhering to safety standards is not just a regulatory requirement; it’s a cornerstone of the industry’s reputation and customer trust. Here’s an in-depth look at how these factors shape the operations of commercial air fryer factories:

The meticulous process of quality assurance begins with the sourcing of raw materials. Factories rigorously select high-quality components that meet the specific requirements for air fryer production. From durable stainless steel to energy-efficient heating elements, every part is scrutinized to ensure it meets the stringent standards necessary for a commercial-grade appliance.

Safety is paramount in the design phase of commercial air fryers. Engineers and designers collaborate closely to create units that not only perform efficiently but also prioritize user safety. This includes incorporating features like automatic shut-off mechanisms, overheat protection, and child safety locks to prevent accidents. The design also takes into account the risk of electrical hazards, with robust insulation and grounding systems to safeguard against potential fires.

During the assembly process, each component is meticulously fitted together. Workers are trained to adhere to precise guidelines, ensuring that each air fryer is assembled correctly and without any loose connections or faulty parts. Quality control inspectors regularly monitor the line, checking for defects and ensuring that each unit meets the factory’s high standards before it moves to the next stage.

Testing is a critical part of the quality control process. Before a commercial air fryer leaves the factory, it undergoes a series of rigorous tests to ensure it operates as intended. These tests include functional checks, where the fryer is run through various cycles to confirm that it can handle a range of cooking temperatures and times. Additionally, durability tests are conducted to ensure the unit can withstand the demands of continuous commercial use.

Safety standards are not just about the product itself; they also extend to the factory environment. Factories must comply with local and international health and safety regulations, which include maintaining clean and well-organized workspaces. Regular maintenance of machinery is crucial to prevent accidents and ensure that all equipment is in optimal working condition.

Employee training is a cornerstone of quality control and safety in commercial air fryer factories. Workers are educated on the proper handling of materials, machinery, and the use of personal protective equipment (PPE). This training not only minimizes the risk of accidents but also ensures that the manufacturing process is efficient and error-free.

In the realm of safety standards, compliance with certifications is non-negotiable. Many commercial air fryer factories hold certifications from organizations such as UL (Underwriters Laboratories) or CE (Conformité Européenne), which signifies that their products meet specific safety and quality criteria. These certifications are often a requirement for selling products in certain markets and are a testament to the factory’s commitment to safety.

As technology advances, so does the need for continuous improvement in quality control and safety. Factories invest in state-of-the-art testing equipment and software to monitor and analyze performance data, allowing them to identify and address any potential issues early on. This proactive approach helps in preventing defects and ensuring that each air fryer that leaves the factory is not just safe but also reliable.

In the world of commercial air fryer manufacturing, the pursuit of excellence in quality control and safety is an ongoing journey. It requires a combination of careful material selection, meticulous design, rigorous testing, and unwavering adherence to safety protocols. By doing so, factories not only protect their customers but also uphold the integrity of their brand and the industry as a whole.

In the fast-paced world of commercial air fryer manufacturing, data and analytics have become invaluable tools in driving product development. From understanding market trends to optimizing production processes, the integration of data-driven insights has revolutionized how factories approach innovation and customer satisfaction. Here’s a glimpse into how these elements play a pivotal role in shaping the future of air fryer technology.

The collection of vast amounts of data from various sources, including customer feedback, market research, and sales reports, provides a comprehensive view of consumer needs and preferences. This data is then meticulously analyzed to identify patterns and insights that can guide product development strategies. For instance, if consumer surveys reveal a growing preference for healthier cooking options, the data team can flag this trend and communicate it to the product development team.

Analytics tools are employed to sift through this data, revealing not just what consumers want, but also how they interact with current products. This user behavior analysis can highlight areas for improvement, such as interface design, ease of use, or even the types of cooking functions that are most sought after. By understanding these nuances, manufacturers can tailor their products to better meet customer expectations.

Innovation is often driven by the identification of emerging technologies and materials that can enhance the performance and longevity of air fryers. Data analytics can pinpoint which technologies are gaining traction in the market, allowing manufacturers to stay ahead of the curve. For example, advancements in heat distribution technology or the integration of smart features can be identified and incorporated into new models.

The role of data in cost optimization is equally significant. By analyzing production data, factories can identify inefficiencies and areas where costs can be reduced without compromising quality. This might involve streamlining supply chains, optimizing inventory levels, or even finding more cost-effective materials. The financial insights derived from data analytics can lead to more sustainable and profitable operations.

Safety is a paramount concern in the manufacturing of commercial kitchen appliances, and data and analytics play a crucial part in ensuring compliance with safety standards. By tracking recall data and customer complaints, manufacturers can quickly identify potential safety issues and address them proactively. This not only protects consumers but also maintains the brand’s reputation.

Product development is an iterative process, and data-driven insights facilitate continuous improvement. Regular feedback from customers, paired with real-time analytics, allows for the rapid prototyping and testing of new features or designs. This agile approach means that products can be refined and updated based on the latest market intelligence and consumer feedback.

Furthermore, the use of predictive analytics can help anticipate future market demands. By analyzing historical sales data and external factors such as economic trends and lifestyle changes, manufacturers can forecast which features or functionalities will be in high demand in the coming years. This forward-thinking approach allows for strategic planning and the development of products that are well-positioned to succeed in the long term.

Collaboration between different departments within the factory is also enhanced by data and analytics. Sales, marketing, production, and R&D teams can all contribute to the product development process by sharing insights and data. This cross-functional approach ensures that all aspects of the business are aligned with the overarching goal of creating products that resonate with customers.

In conclusion, the role of data and analytics in product development within commercial air fryer factories cannot be overstated. From informing strategic decisions to optimizing operations and ensuring safety, these tools are the backbone of a modern, efficient, and customer-centric manufacturing process. As the industry continues to evolve, the reliance on data-driven insights will only grow, leading to more innovative and successful products that meet the ever-changing needs of consumers.

The shift towards sustainability has been a transformative force across various industries, and the commercial air fryer market is no exception. As manufacturers grapple with the need to balance innovation with environmental responsibility, several key aspects are reshaping air fryer production.

Manufacturers are increasingly focusing on the sourcing of raw materials. Recycled plastics and sustainable wood sources are becoming more prevalent, reducing the carbon footprint of the production process. This not only aligns with consumer demands but also helps in maintaining a competitive edge in a market that values eco-conscious products.

Energy efficiency is a cornerstone of sustainable air fryer production. Advances in insulation and heat exchange technology have led to fryers that consume less energy while maintaining the desired cooking temperatures. These improvements not only lower operational costs for businesses but also contribute to a smaller environmental impact.

The design of air fryers is also being reevaluated to ensure that they are not only effective but also energy-efficient. Smaller, more compact models are being developed to reduce the energy required for heating and cooling. Additionally, smart technology is being integrated to allow for precise control of cooking times and temperatures, further optimizing energy use.

In the realm of manufacturing processes, the industry is turning to cleaner and more efficient production methods. Water-based paints and coatings are replacing solvent-based alternatives, reducing both the amount of waste produced and the emissions released into the atmosphere. The adoption of lean manufacturing principles also helps in minimizing waste and improving overall efficiency.

Recycling and waste reduction programs are being implemented at commercial air fryer factories. This includes the recycling of packaging materials and the reuse of by-products from the manufacturing process. By turning what was once waste into valuable resources, manufacturers are not only cutting costs but also demonstrating their commitment to sustainability.

The importance of energy management systems cannot be overstated. These systems monitor and control the energy use within factories, ensuring that energy is used efficiently and wastefully. Advanced sensors and automation technologies are employed to detect inefficiencies and adjust processes accordingly.

Innovation in cooling systems is also a significant aspect of sustainable air fryer production. Traditional cooling methods often consume a considerable amount of energy. New, more efficient cooling technologies are being developed, such as phase-change materials that can absorb and release heat more effectively, reducing the energy needed for cooling.

The integration of renewable energy sources is another area of focus. Solar panels and wind turbines are being installed on factory roofs to harness clean energy. This not only reduces reliance on fossil fuels but also serves as a statement of the manufacturer’s dedication to sustainable practices.

Lastly, the training of factory workers plays a crucial role in maintaining high sustainability standards. Employees are educated on the importance of energy conservation, waste reduction, and the use of sustainable materials. This ensures that every aspect of the production process is aligned with the company’s sustainability goals.

In conclusion, sustainability and energy efficiency in air fryer production are not just trends but essential components of a forward-thinking manufacturing strategy. By embracing these principles, manufacturers are not only contributing to a healthier planet but also creating a competitive advantage in a market that values eco-friendly products.

The landscape of commercial air fryer factories is rapidly evolving, with a focus on not just innovation but also on the future of food preparation. As we look ahead, several key trends are shaping the industry, from advancements in technology to the rise of sustainability and energy efficiency.

In the realm of technology, we’re seeing a surge in smart features that cater to the modern consumer’s demand for convenience and control. Air fryers are now equipped with touchscreens, allowing users to select from a variety of cooking modes and settings. These advancements make it easier for users to achieve perfect results with minimal effort.

Energy efficiency has become a cornerstone of air fryer production. Factories are investing in cutting-edge technology that reduces power consumption while maintaining high cooking temperatures. This shift is driven by consumer awareness of environmental issues and the desire for appliances that are both cost-effective and eco-friendly.

The integration of IoT (Internet of Things) into air fryer manufacturing has opened up new possibilities. Sensors and connectivity allow for real-time monitoring and predictive maintenance, which not only prolongs the life of the appliance but also ensures that it operates at peak efficiency.

Material science is another area experiencing significant breakthroughs. The use of high-quality, non-toxic materials is paramount, especially as health concerns around cookware materials have gained traction. Companies are now exploring sustainable alternatives that offer the same performance without the health risks.

As the demand for commercial air fryers grows, so does the need for scalability in manufacturing. Factories are implementing flexible production lines that can quickly adapt to changes in demand and product design. This agility is crucial for staying competitive in a market that is constantly evolving.

Quality control is paramount in the production of commercial air fryers. Stringent testing protocols are in place to ensure that each unit meets safety standards and performs as expected. This includes rigorous testing for electrical safety, heat distribution, and durability under various conditions.

Safety standards are not just about meeting regulatory requirements; they are about building trust with consumers. Commercial air fryer factories are investing in certifications from reputable organizations to verify their compliance. This not only ensures that the product is safe but also gives businesses a competitive edge.

The rise of e-commerce has changed the distribution landscape for air fryer manufacturers. Online sales have increased, and factories are now focusing on packaging that not only protects the product during shipping but also enhances the brand’s image. Custom packaging that reflects the brand’s values and design aesthetic is becoming a key differentiator.

The global supply chain is also being reshaped by the demand for commercial air fryers. Factories are diversifying their sourcing to reduce reliance on single suppliers, which helps mitigate risks and ensures a steady supply of materials. This diversification also supports local economies and encourages ethical sourcing practices.

Innovation in cooking methods is another trend influencing the manufacturing process. The development of new recipes and cooking techniques has led to the creation of air fryer models specifically designed for certain types of food preparation. This specialization allows for greater precision and consistency in cooking outcomes.

As we consider the future of commercial air fryer factories, we must also acknowledge the role of training and development. Factories are investing in their workforce to ensure that employees have the skills and knowledge necessary to produce high-quality products. This investment in human capital is crucial for maintaining a competitive edge.

Lastly, the future of commercial air fryer factories lies in their ability to adapt to regulatory changes and consumer preferences. The industry is subject to frequent updates in safety standards and environmental regulations, and factories must be agile enough to navigate these changes without compromising on quality.

In conclusion, the future of commercial air fryer factories is one of continuous innovation, sustainability, and customer-centricity. By focusing on technological advancements, energy efficiency, and safety, these factories are not only meeting the current demand but also paving the way for the next generation of kitchen appliances.