Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

The kitchen equipment industry is undergoing a transformation, with OEM collaboration models gambling a vital function. As clients’ demand for , personalized kitchen appliances continues to grow, the NSF-certified contact grills, with their excellent high-quality and protection overall performance, are becoming a brand new favorite inside the marketplace. this newsletter will delve into the software and improvement of oem collaboration models in the kitchen appliance enterprise, as well as the market ability and future potentialities of NSF-certified contact grills.

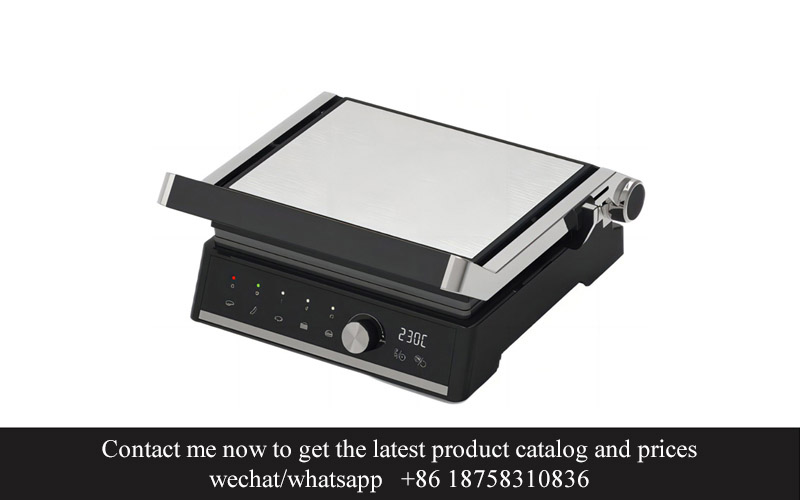

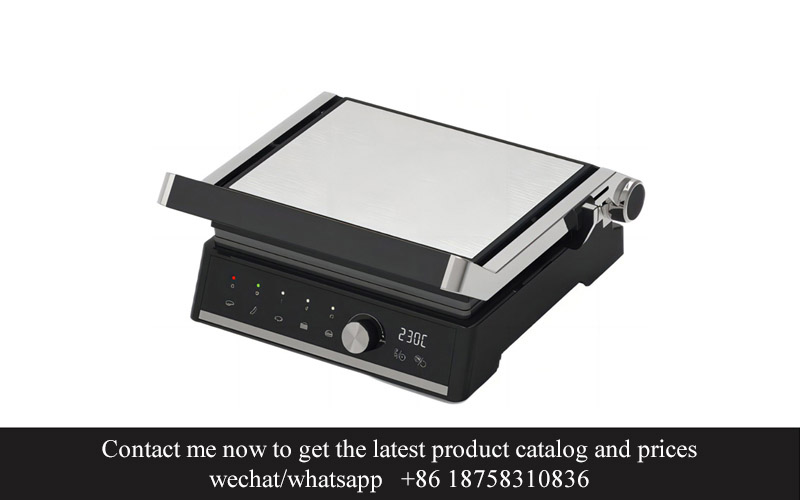

NSF-licensed contact grilling factories have set the benchmark for fine and protection within the kitchen equipment industry with their stringent manufacturing standards and high-quality first-rate management. Adhering to the international standards set by means of NSF (countrywide Sanitation basis), every grill is fastidiously inspected to make sure fine from raw fabric procurement to completed product dispatch, with every step meticulously managed.

The manufacturing unit employs advanced automatic manufacturing strains and introduces internationally leading production technologies and equipment to make sure uniform heating and stable performance of the grills. In terms of cloth selection, the manufacturing facility insists on the use of , high-temperature-resistant, and corrosion-resistant chrome steel, as well as environmentally friendly coating substances, which now not only expand the product’s service lifestyles however also guarantee consumer safety.

NSF certification requires the manufacturing unit to set up a comprehensive exceptional control machine, which includes everyday inner audits and reviews via outside certification our bodies. The manufacturing unit boasts a professional excellent inspection team that fastidiously exams the heating performance, protection, and simplicity of cleansing of the grills, ensuring that the products meet NSF requirements. In phrases of protection, the manufacturing unit will pay unique attention to the anti-leakage layout of the grill and the reliability of the emergency forestall button, providing clients with comprehensive protection guarantees.

during the production process, the factory additionally emphasizes environmental protection and strength saving. via optimizing manufacturing strategies, decreasing strength intake, the manufacturing unit now not only lowers production prices but additionally reduces environmental pollution. In product design, the manufacturing facility takes under consideration consumer comfort and luxury, making the grill clean to clean and maintain even as imparting an green cooking revel in.

The achievement of NSF certification isn’t always handiest a recognition of the manufacturing facility’s pleasant and protection manipulate talents but additionally a dedication to purchaser self belief. with the aid of continuously innovating in technology and first-rate control, the factory has stronger the competitiveness of its merchandise, triumphing good sized recognition inside the kitchen equipment industry. In ultra-modern increasingly competitive kitchen equipment marketplace, the NSF-certified touch grilling manufacturing unit sticks out with its excessive fine and protection.

The application and improvement of the OEM cooperation version within the kitchen equipment industry have become a massive using force for market innovation and commercial upgrading. The center of this version lies in the manufacturers presenting custom designed services and products to logo clients, which meets the marketplace’s demand for personalized and expert merchandise.

inside the kitchen equipment enterprise, the OEM cooperation model is especially pondered within the following components:

custom designed Product layout: With the increasing necessities of customers for the capability and appearance of kitchen appliances, the OEM cooperation allows logo merchants to customize merchandise that meet particular styles and functions in keeping with marketplace demand. for example, positive high-give up brands may additionally need to customise ovens with precise heating technologies or clever capabilities, and OEM factories will layout and produce based totally on those requirements.

supply Chain Optimization: beneath the OEM version, factories usually have a mature supply chain control machine that can correctly integrate uncooked fabric procurement, production manufacturing, first-class manage, and other hyperlinks, ensuring product consistency and reliability. This green deliver chain control facilitates to reduce costs and enhance production performance.

generation Sharing and Innovation: via OEM cooperation, kitchen equipment manufacturers can percentage technical assets with emblem merchants, reaching technological innovation and product upgrading. logo traders can leverage the technical benefits of manufacturers to release ahead-looking products that meet the market’s pursuit of high satisfactory and functionality.

four. speedy market response: OEM factories commonly have bendy production skills and speedy market reaction capabilities. inside the face of marketplace modifications, they are able to quick alter production plans to fulfill the brand merchants’ requirements for brand new product release timing.

five. emblem Enhancement: For logo traders, OEM cooperation allows to enhance emblem photo. via cooperating with manufacturers, brand merchants can ensure product fine and enhance customer believe inside the brand.

all through the improvement manner, the OEM cooperation version is likewise evolving:

The utility and improvement of the OEM cooperation model within the kitchen appliance industry now not simplest promotes product innovation but additionally facilitates the upgrading and optimization of the industrial chain. within the future, this model is predicted to play a greater role in the kitchen equipment enterprise, bringing extra and value-powerful kitchen appliance products to purchasers.

The OEM cooperation model in the kitchen appliance industry is increasingly more mature. by outsourcing production, organisations not only optimize their very own resources however additionally boost up their market response speed. The cooperative parties paintings intently collectively in product design, research and improvement, and production production, at the same time promoting product innovation. The OEM model has facilitated the integration of the commercial chain, significantly shortening the cycle from product studies and development to marketplace promotion.

As customer demands for the excellent of kitchen appliance merchandise upward thrust, the function of the OEM cooperation in the kitchen equipment enterprise is becoming more and more prominent. emblem owners cognizance on logo constructing and market expansion, whilst producers deal with product manufacturing, accomplishing the premiere allocation of sources via specialised department of labor. below this model, manufacturers can listen their wonderful resources to improve manufacturing efficiency and product exceptional, while additionally reducing manufacturing expenses.

The diversification of market call for has additionally driven the development of the OEM cooperation model. extraordinary regions and consumer agencies have various necessities for the functionality, layout, and dimensions of kitchen home equipment. OEM cooperation can quick modify merchandise to satisfy the personalized demands of purchasers. furthermore, with the of the internet and the upward thrust of e-trade channels, the utility of the OEM cooperation model inside the kitchen equipment industry has emerge as extra giant, offering emblem proprietors with more numerous income channels.

in the face of more and more fierce marketplace opposition, kitchen equipment agencies can speedy respond to marketplace changes and reduce business dangers via OEM cooperation. in the meantime, manufacturers, thru taking on orders from multiple manufacturers, acquire wealthy production experience and marketplace remarks, similarly enhancing their competitiveness. additionally, OEM cooperation has promoted the upgrading of the economic chain, using the kitchen appliance enterprise closer to a better-end and sensible course.

With the growing focus of inexperienced and environmental safety, electricity-saving and environmentally pleasant kitchen appliances have end up the mainstream inside the market. The OEM cooperation version helps establishments to acquire unique alignment among product studies and improvement and market call for, accelerating the velocity of recent product development. within the fashion of intelligence and personalization, kitchen home equipment will region more emphasis on consumer revel in, and OEM cooperation will become a key driving pressure for the development of the kitchen equipment industry.

average, the software and development of the OEM cooperation model in the kitchen appliance enterprise have now not simplest progressed product quality and logo competitiveness but also promoted the combination and upgrading of the economic chain. searching ahead, with the non-stop development of era and changes in marketplace demand, the OEM cooperation version will continue to play a extensive function, bringing new development opportunities to the kitchen appliance industry.