Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the culinary landscape continues to evolve, innovative kitchen appliances are stepping into the spotlight, reshaping the way we prepare and enjoy our meals. One such appliance that has been making waves is the industrial panini press. Once a staple in the sandwich shops, this versatile gadget is now revolutionizing kitchen efficiency across various industries. Join me as we delve into the fascinating world of industrial panini presses and explore why they might just be the next big thing in kitchen appliances.

The culinary world has always been about innovation and efficiency, and the latest trend that’s been heating up the kitchen is the industrial panini press. Once the domain of small sandwich shops, these heavy-duty appliances are now making waves in the foodservice industry, and for good reason. The rise of industrial panini presses is not just a fleeting trend; it’s a game-changer that’s reshaping the way we think about sandwich preparation.

Industrial panini presses are not your average kitchen gadget. Designed with commercial kitchens in mind, these units are built to handle high-volume production without skipping a beat. They’re the kind of presses that can cook multiple sandwiches at once, making them perfect for busy cafes, delis, and restaurants that rely on speed and consistency to keep customers satisfied.

The first thing that sets industrial panini presses apart is their robust construction. Made from stainless steel and equipped with heavy-duty springs, these presses can withstand the rigors of continuous use. Unlike home models, which might struggle with thick or double-stack sandwiches, industrial presses are designed to seal and cook even the thickest of bread with ease. This capability is a game-changer for businesses looking to offer gourmet sandwiches that don’t compromise on quality.

Another standout feature is the temperature control. Industrial panini presses are often equipped with precise temperature settings, allowing chefs to achieve the perfect level of crispiness on the outside while keeping the inside warm and soft. This control is crucial for creating a professional-grade sandwich that’s as visually appealing as it is delicious.

The versatility of industrial panini presses is another reason for their surge in popularity. These presses are not just for sandwiches. They can also be used to cook wraps, burgers, and even flatbreads, making them a versatile tool for any kitchen. The ability to quickly switch from one type of food to another is a huge time-saver, especially during peak hours when every second counts.

The market for industrial panini presses has seen a significant growth in recent years, and it’s easy to see why. As health-conscious consumers continue to seek out quick, nutritious meals, the demand for fresh, made-to-order sandwiches has skyrocketed. Businesses that can offer this kind of menu item have a competitive edge, and industrial panini presses are the key to producing these items at scale.

Consumer trends play a crucial role in the rise of industrial panini presses. The trend towards gourmet and artisanal food has fueled a demand for high-quality, unique sandwiches. These presses allow businesses to experiment with different ingredients and flavors, creating a diverse menu that caters to a wide range of tastes. From classic Italian subs to fusion creations, the possibilities are endless.

In terms of kitchen efficiency, industrial panini presses are a godsend. They cook food quickly and evenly, reducing wait times and ensuring that every sandwich is consistent. For operators looking to streamline their workflow, these presses are a no-brainer. They’re also easier to clean than many other kitchen appliances, which is a huge plus for busy kitchens that need to maintain a hygienic environment.

Several case studies have highlighted the success of businesses that have invested in industrial panini presses. For instance, a local café that added a panini press to their menu saw a surge in sales, as customers flocked to try the freshly cooked, gourmet sandwiches. The café’s owners attribute the increase in business directly to the high-quality sandwiches that the press helped them produce.

Looking ahead, the future of sandwich making seems to be bright for those who have embraced industrial panini presses. As the industry continues to evolve, these presses are likely to become even more sophisticated, with features that further enhance their versatility and efficiency. Chefs and kitchen managers who are quick to adopt these innovations will be well-positioned to meet the demands of the modern consumer.

In conclusion, the rise of industrial panini presses is not just a trend; it’s a transformation in the culinary industry. These powerful appliances are changing the way we think about sandwich preparation, offering a solution that’s both efficient and effective. For any business looking to stay ahead in the competitive foodservice market, an industrial panini press could be the key to their success.

Industrial panini presses have been making quite the stir in the culinary industry, and for good reason. These aren’t your average kitchen gadgets; they’re powerful tools designed for high-volume, commercial use. Let’s delve into what sets them apart from their domestic counterparts.

Firstly, the build quality of industrial panini presses is far superior. They are constructed with heavy-duty materials that can withstand rigorous use day in and day out. These presses are built to last, with robust frames and heat-resistant components that ensure they can handle the intense heat required for consistent, professional-grade results.

One of the standout features of industrial panini presses is their even heat distribution. These units are engineered to maintain a steady temperature across the entire pressing surface, ensuring that every sandwich, wrap, or grilled cheese is cooked to perfection. This level of precision is crucial in a commercial kitchen where speed and consistency are key.

The size of industrial panini presses is another differentiating factor. They are typically larger than domestic models, allowing for the simultaneous cooking of multiple sandwiches. This is particularly beneficial in busy environments like cafes, restaurants, and catering services where time is of the essence. The larger surface area also means more space for a variety of fillings, making them versatile for a wide range of menu items.

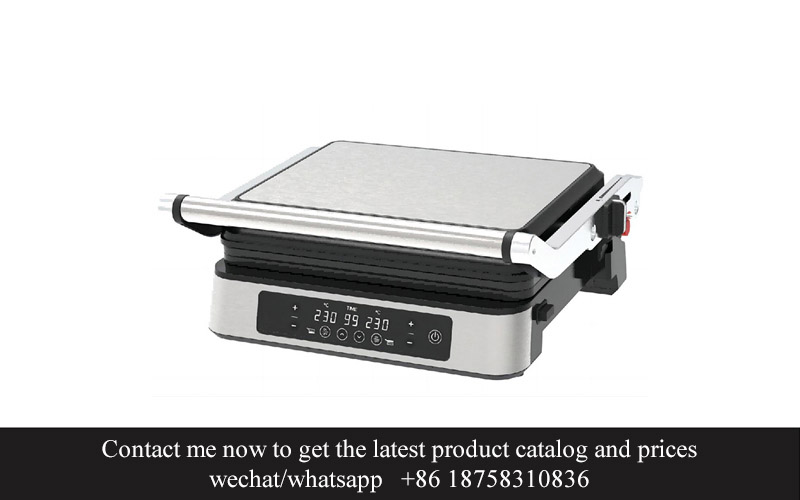

The controls on industrial panini presses are often more sophisticated than those found in domestic models. These commercial units may come with adjustable temperature settings, allowing chefs to tailor the cooking process to different types of bread and fillings. Some even feature digital displays and timers, making it easy to monitor the cooking time and prevent overcooking.

Durability is a non-negotiable in the commercial kitchen, and industrial panini presses deliver on this front. They are designed to be easy to clean, with removable plates and surfaces that can be washed in commercial dishwashers. This not only ensures that the presses are ready for action at a moment’s notice but also helps maintain a hygienic cooking environment.

Innovation in design has led to some impressive features in the latest models of industrial panini presses. Features like adjustable pressure, which allows for a customizable cooking experience, are becoming increasingly common. Some presses even have integrated cutting boards, making it possible to prep and cook in the same space, thus saving valuable counter space.

Safety is paramount in commercial kitchens, and industrial panini presses are equipped with safety features to prevent accidents. These may include cool-touch handles, child safety locks, and automatic shut-offs to prevent overheating. These features are not just for peace of mind; they’re essential for maintaining a safe working environment.

Another unique aspect of industrial panini presses is their ability to handle high heat without compromising their lifespan. Unlike some domestic presses that may become less effective over time due to the buildup of heat, these commercial units are built to withstand prolonged exposure to high temperatures, ensuring they continue to perform at their best.

In the world of commercial cooking, speed is everything. Industrial panini presses are designed with speed in mind. They can cook multiple sandwiches at once, reducing wait times and keeping customers happy. This is particularly valuable during peak hours when a steady flow of customers can make or break a business.

Finally, the design of industrial panini presses often reflects a commitment to sustainability. Many models are energy-efficient, which not only helps reduce operational costs but also contributes to a greener planet. This eco-friendly approach is becoming increasingly important to both businesses and consumers.

In summary, the allure of industrial panini presses lies in their robust build, precise temperature control, versatility, user-friendly features, and safety considerations. They are a testament to the ongoing innovation in commercial kitchen equipment, and it’s no wonder they’re becoming a staple in the culinary industry.

Industrial panini presses have emerged as a versatile kitchen staple, transcending their humble origins in sandwich shops to become a staple in catering operations. These robust appliances are not just for grilling the classic panini anymore; they’ve become a go-to tool for a wide array of culinary applications.

Their compact design and ability to cook a sandwich in mere minutes make them a favorite in quick-service restaurants and cafes. But that’s just the tip of the sandwich. Here’s how industrial panini presses are being creatively utilized across different segments:

In gourmet cafes, the panini press is used to craft sophisticated open-face sandwiches, often with a twist. Artisanal breads, gourmet fillings, and unique toppings are pressed to perfection, creating visually stunning and delicious creations that are as much a treat for the eyes as for the taste buds.

Caterers have also embraced the industrial panini press for its ability to quickly produce large quantities of sandwiches for events. Whether it’s a corporate gathering or a wedding, these presses can churn out high-quality sandwiches at a pace that keeps the catering staff on their toes and the guests satisfied.

Sports stadiums and concert venues often find themselves in need of quick and efficient food options for large crowds. Industrial panini presses fit the bill perfectly, allowing for the rapid preparation of a variety of sandwiches, wraps, and other handheld items that can be consumed on the go.

In educational institutions, from schools to universities, the panini press is a hit with students and staff alike. It’s a convenient way to provide nutritious and delicious meal options during lunch breaks, with the added bonus of customizable sandwiches that cater to different dietary preferences and restrictions.

Health-conscious consumers are also gravitating towards industrial panini presses. These appliances make it easy to create homemade sandwiches using fresh, whole-grain breads and a variety of healthy toppings. The presses ensure that the ingredients are cooked evenly and retain their nutrients, making them a popular choice for those looking to maintain a balanced diet.

For casual diners, the panini press has become a symbol of homemade comfort food. It’s not uncommon to see these appliances in the back of diners and small restaurants, where they’re used to cook up classic sandwiches that evoke a sense of nostalgia and warmth.

Even in the fast-casual sector, where everything is about speed and convenience, the industrial panini press has found its place. It allows for the quick preparation of gourmet sandwiches that appeal to customers looking for something a bit more upscale than the standard fast-food fare.

Beyond sandwiches, the versatility of the industrial panini press extends to a variety of other items. It can be used to toast bagels, grill cheese, prepare wraps, or even cook mini pizzas. Its even heat distribution ensures that every item comes out with a beautiful crust and a melt-in-your-mouth texture.

The ease of use is another factor that contributes to the press’s popularity. These appliances are simple to operate, require minimal cleanup, and are built to withstand heavy use, making them a practical choice for busy kitchens.

In summary, the industrial panini press’s adaptability to various cooking techniques and its ability to produce high-quality food at a rapid pace have made it an indispensable tool in the culinary industry. Whether it’s for a high-end cafe, a bustling catering operation, or a casual eatery, the panini press continues to play a significant role in shaping the dining experience for customers worldwide.

Industrial panini presses have come a long way from the humble countertop models found in home kitchens. These robust appliances are now the backbone of many a commercial kitchen, from bustling sandwich shops to large-scale catering operations. Here’s a closer look at the innovative features that set top-notch industrial panini presses apart.

Even Heat Distribution: One of the standout features of a high-quality industrial panini press is its ability to distribute heat evenly across the entire cooking surface. This ensures that every sandwich is cooked to perfection, with a crispy outer layer and a melty, gooey interior. Look for presses with precise temperature controls to guarantee consistent results every time.

Adjustable Heat Settings: Not all sandwiches are created equal, and a top industrial panini press understands this. With adjustable heat settings, chefs can tailor the cooking temperature to the specific needs of their menu items. Whether you’re grilling a classic ham and cheese or searing a gourmet turkey breast, the ability to fine-tune the heat is invaluable.

Non-Stick Coating: Keeping your kitchen clean is essential, and a non-stick coating on the press can make a world of difference. This feature not only simplifies the cleaning process but also reduces the risk of food sticking, which can lead to uneven cooking and wasted product.

Fast Heat-Up Time: In a busy kitchen, time is money. A top-notch industrial panini press should be able to reach optimal cooking temperature quickly, minimizing downtime and keeping the line moving. Look for models with rapid heat-up capabilities to enhance productivity.

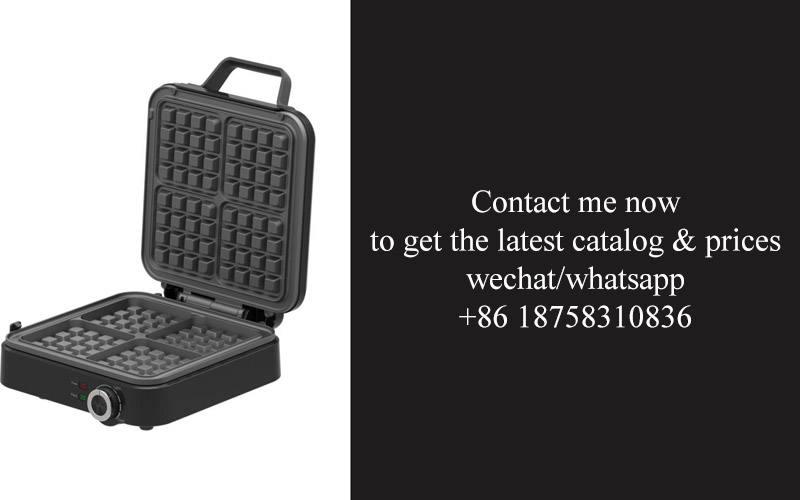

Multiple Cooking Surface Options: While the traditional flat press is great for sandwiches, some industrial presses offer additional surfaces for a variety of cooking styles. Griddle plates, waffle irons, and even pizza ovens can be added to the mix, allowing for a diverse menu that can cater to different tastes and preferences.

Safety Features: Safety should always be a top priority in a commercial kitchen. Modern industrial panini presses come with features like cool-touch handles, automatic shut-off functions, and non-slip bases to prevent accidents and ensure a safe work environment.

Sturdy Construction: The durability of an industrial panini press is crucial for long-term reliability. Look for presses made with high-quality materials like stainless steel, which not only withstands the rigors of daily use but also contributes to the appliance’s overall longevity.

Easy to Clean Design: Despite their robust build, top industrial panini presses are designed with ease of cleaning in mind. Removable parts, smooth surfaces, and the absence of nooks and crannies where food particles can get trapped make for a more manageable cleaning process.

User-Friendly Controls: Intuitive controls are essential for a press that can be used by a variety of kitchen staff. Look for models with clear displays, easy-to-understand buttons, and programmable settings that can be adjusted to suit different cooking styles and preferences.

Portability and Space-Saving Design: In kitchens with limited space, a compact and portable industrial panini press can be a game-changer. These models are designed to be moved around easily and can often be stored vertically to save valuable counter space.

Warranty and Customer Support: A reliable warranty and excellent customer support are indicators of a manufacturer’s confidence in their product. When investing in an industrial panini press, ensure that the manufacturer offers comprehensive coverage and responsive customer service.

Energy Efficiency: In an era where sustainability is a growing concern, energy-efficient appliances are becoming more important. An industrial panini press that consumes less energy not only reduces operational costs but also contributes to a greener kitchen environment.

By focusing on these innovative features, you can select an industrial panini press that not only meets the demands of your kitchen but also enhances your ability to serve high-quality, consistent food to your customers.

In the culinary landscape, the demand for industrial panini presses has been on a steady incline, reflecting a shift in the way we approach food preparation and service. These robust appliances have transcended their original purpose in sandwich shops to become integral in various foodservice operations. Let’s delve into the reasons behind this burgeoning popularity.

The Rise of Health-Conscious ConsumersModern diners are increasingly health-conscious, seeking out lighter, more nutritious options. Industrial panini presses offer a perfect solution by allowing for the cooking of ingredients with minimal added fats, which can lead to healthier, yet satisfying, meals.

Versatility in Menu OfferingsWhat sets industrial panini presses apart is their ability to cook a wide array of food items. From sandwiches and wraps to flatbreads and grilled cheeses, these machines can transform a simple piece of bread into a gourmet meal in mere minutes. This versatility has made them a favorite among chefs looking to expand their menu options.

Efficiency and Speed in High-Volume SettingsFor operators in fast-paced environments such as cafes, delis, and food trucks, efficiency is key. Industrial panini presses are designed to handle high volumes quickly and consistently. Their ability to cook multiple sandwiches simultaneously means less waiting time for customers and a smoother operation overall.

Customization and PersonalizationOne of the standout features of these presses is the level of customization they offer. They can accommodate various bread sizes, thicknesses, and shapes, allowing establishments to create signature dishes that stand out in a crowded market. This level of personalization has become a major draw for consumers looking for unique culinary experiences.

Cost-EffectivenessDespite their robust construction and commercial-grade design, industrial panini presses are surprisingly cost-effective. Their durable build ensures a long service life, reducing the need for frequent replacements. Additionally, the energy-efficient nature of these presses helps lower operating costs in the long run.

Ease of Maintenance and CleaningMaintaining a commercial kitchen can be a daunting task, but industrial panini presses are designed with cleaning in mind. Many models feature non-stick surfaces that are easy to clean, and their modular design allows for quick and straightforward maintenance. This ease of maintenance is a crucial factor for businesses that want to keep their kitchens running smoothly.

Enhanced AestheticsIn an era where the visual appeal of food is just as important as its taste, the sleek design of industrial panini presses cannot be overlooked. These appliances can add a touch of modern elegance to any kitchen, making them not just functional but also stylish.

Global Culinary InfluenceThe culinary world is a melting pot of influences, and industrial panini presses have been influenced by international cuisines. Features like adjustable heat settings and various press plates allow chefs to experiment with different styles of cooking, from the charred flavors of a grill to the crispy edges of a panini press.

Innovation in Materials and TechnologyManufacturers have continuously innovated in the materials and technology used in industrial panini presses. From high-quality stainless steel construction to advanced heating elements, these machines are built to last and deliver exceptional performance.

Brand Loyalty and Customer RetentionAs consumers become more engaged with their dining experiences, they often develop a preference for the brands and restaurants that offer them. With industrial panini presses as a centerpiece of their operations, many businesses have seen an increase in customer loyalty and retention.

In summary, the growing demand for industrial panini presses is a testament to their adaptability, efficiency, and the value they bring to a diverse range of foodservice operations. As the culinary landscape continues to evolve, it’s clear that these versatile appliances are here to stay, driving innovation and enhancing the dining experience.

The surge in popularity of industrial panini presses has sparked a frenzy among consumers, and it’s not hard to see why. These versatile appliances have become a staple in a variety of settings, from bustling sandwich shops to high-end catering services. Let’s delve into the reasons behind the growing demand for these robust machines.

One key factor is the sheer convenience they offer. In a world where time is a precious commodity, industrial panini presses can churn out perfect sandwiches in mere minutes. This efficiency is particularly appealing to busy consumers who are looking for quick, delicious meals without sacrificing quality.

The ability to customize is another draw. Many industrial presses come with adjustable heat settings, allowing users to achieve the perfect level of crispness and melt for different types of bread and fillings. Whether it’s a classic ham and cheese or a gourmet creation with avocado and pesto, these presses cater to a wide range of tastes and preferences.

Moreover, the uniformity in the cooking process ensures that every sandwich is cooked to perfection, every time. This consistency is crucial for businesses that rely on repeat customers and word-of-mouth referrals. The predictability of the results means that customers can count on a delicious meal, no matter how many they order.

In addition to their practicality, industrial panini presses have also become a symbol of quality and professionalism. The sleek designs and sturdy construction of these appliances convey a sense of reliability and expertise. For businesses looking to elevate their brand image, investing in an industrial panini press can be a strategic move.

The versatility of these presses is undeniable. They are not just limited to sandwiches; many models can also be used to toast bagels, melt cheese on pizzas, or even sear vegetables. This multipurpose functionality means that businesses can expand their menu offerings without the need for additional equipment.

As health and wellness trends continue to shape consumer preferences, industrial panini presses have stepped up to the plate. The ability to create fresh, homemade sandwiches filled with wholesome ingredients has become increasingly popular. These presses allow customers to enjoy a nutritious meal without the additives and preservatives found in processed foods.

The rise of food trucks and pop-up restaurants has also contributed to the demand for industrial panini presses. These mobile operations require lightweight, portable equipment that can withstand the rigors of the road. The compact size and durability of these presses make them ideal for such environments.

Social media has played a significant role in the popularity of industrial panini presses. The visual appeal of beautifully toasted sandwiches, often shared on platforms like Instagram and Pinterest, has sparked a desire for these devices among home cooks and food enthusiasts. The ability to create impressive dishes at home has become a status symbol, fostering a sense of community and camaraderie among users.

Furthermore, the convenience factor extends to maintenance and cleaning. Industrial panini presses are designed with easy-to-clean surfaces and removable parts, making the cleaning process a breeze. This feature is particularly appealing to busy individuals and businesses that want to minimize downtime and keep their kitchens running smoothly.

Lastly, the cost-effectiveness of industrial panini presses cannot be overlooked. While the initial investment may be higher than a traditional countertop press, the long-term savings in terms of time, labor, and menu variety make them a worthwhile investment. For businesses, the ability to offer a unique menu item can translate into increased sales and customer loyalty.

In conclusion, the growing demand for industrial panini presses is a testament to their convenience, versatility, and ability to meet the evolving needs of consumers. From sandwich shops to catering services, these appliances are becoming a staple in the culinary industry, and it’s clear that their popularity is here to stay.

Industrial panini presses have quietly been making waves in the culinary world, transforming the efficiency of kitchens across various industries. These machines, once reserved for the bustling sandwich shops, have now found their way into catering services, corporate cafes, and even high-end restaurants. The reason behind their increasing popularity lies in their versatility and the innovative features that streamline kitchen operations. Let’s delve into how industrial presses are revolutionizing kitchen efficiency.

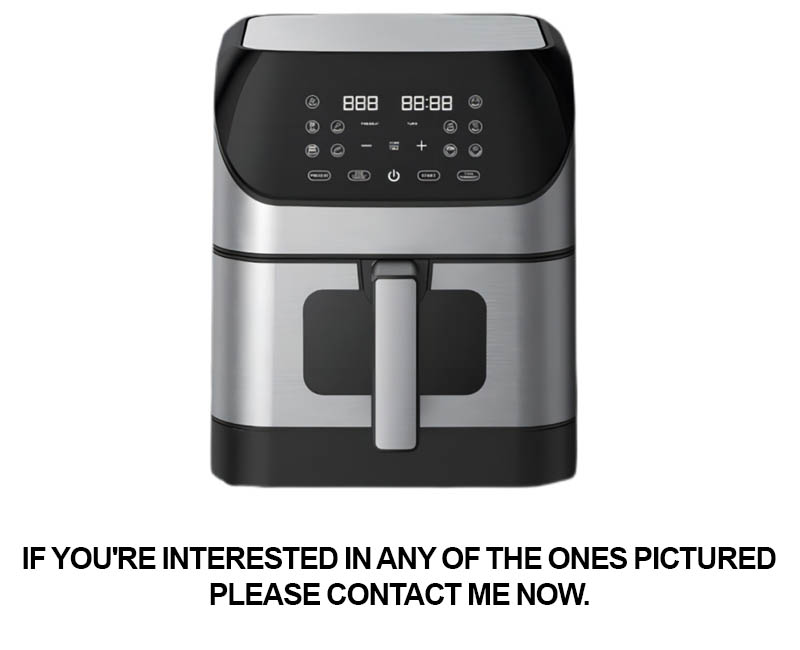

The ability to cook a variety of food items on the same machine is a game-changer. Unlike traditional grills or ovens, industrial panini presses can handle everything from sandwiches to wraps, flatbreads, and even pizza. This single-unit versatility eliminates the need for multiple appliances, saving valuable counter space and reducing the complexity of kitchen layouts.

One of the standout features of these industrial presses is their even heat distribution. Consistent cooking temperatures are crucial for achieving that perfect sear on the bread and the right level of doneness in the fillings. These presses are designed with precise heat controls that ensure every piece of food comes out cooked to perfection, reducing the risk of undercooked or overcooked items.

Speed is another key factor that contributes to the efficiency of industrial presses. In a busy kitchen, time is of the essence. These presses can cook multiple sandwiches at once, significantly reducing the wait time for customers. This is particularly beneficial in catering services where large quantities of food need to be prepared in a short period.

Durability is a non-negotiable in the commercial kitchen environment. Industrial panini presses are built to withstand heavy use, with robust construction and components that can handle the demands of a high-volume kitchen. The heavy-duty materials used in their construction ensure that these presses can last for years, even with frequent use.

Safety features are also a cornerstone of these industrial presses. Many models come equipped with automatic shut-off functions that activate if the press is left unattended or if the cooking process is interrupted. This not only prevents potential fires but also offers peace of mind to kitchen staff, allowing them to focus on other tasks without worrying about the machine.

Ease of use is a critical aspect that can’t be overlooked. The controls on these presses are user-friendly, often featuring simple dials or digital displays that allow for quick adjustments. Cleaning is also a breeze, with most models featuring non-stick surfaces and removable parts that are easy to clean and sanitize.

The energy efficiency of industrial panini presses is another significant advantage. In commercial kitchens where energy costs can be a substantial part of the budget, these presses are designed to be energy-efficient without compromising on cooking performance. This not only saves money in the long run but also contributes to a greener kitchen operation.

Customization is a key factor in the appeal of industrial panini presses. Many models offer adjustable heat settings, allowing chefs to tailor the cooking temperature to the specific needs of their recipes. This flexibility is invaluable for creating unique dishes that cater to different customer preferences.

Innovation doesn’t stop at the design of the presses themselves. Accessories such as adjustable press plates, which can be used to create different shapes and sizes of food items, further expand the capabilities of these machines. This means that kitchens can invest in one press to cater to a wide range of menu items, reducing the need for multiple specialized appliances.

The integration of technology into industrial panini presses has also opened up new possibilities. Some models come with digital timers and programmable settings, allowing chefs to pre-set their preferred cooking times and temperatures. This level of control ensures that even the most complex recipes can be prepared with precision and consistency.

From a business perspective, the return on investment for an industrial panini press is hard to beat. The combination of increased productivity, reduced energy costs, and the ability to offer a wider variety of menu items makes these machines a wise investment for any commercial kitchen.

In conclusion, the rise of industrial panini presses is a testament to the industry’s continuous pursuit of efficiency and innovation. These machines are not just changing the way food is cooked; they are transforming the entire workflow of kitchens, making them faster, safer, and more versatile. It’s no wonder that chefs and kitchen managers are lining up to embrace this technology and see how it can revolutionize their operations.

In the world of foodservice, the adoption of industrial panini presses has become a testament to their versatility and efficiency. Here are a few success stories from businesses that have embraced these innovative appliances and reaped the benefits.

The bustling café on the corner, known for its eclectic menu and warm atmosphere, was struggling to keep up with the demand for its signature panini sandwiches. The old, manual presses were slow and inconsistent, leading to long wait times and a decline in customer satisfaction. That’s when they decided to invest in an industrial panini press. The result? The new press allowed for rapid, even cooking, ensuring each sandwich was delivered hot and perfectly toasted. The café’s reputation for quality and speed grew, attracting a new wave of customers who couldn’t get enough of their freshly made paninis.

A local catering company found itself at a crossroads. With a variety of events to cater to, from intimate gatherings to large corporate functions, they needed a solution that could handle high volumes and diverse menu items. After researching various options, they chose an industrial panini press for its ability to cook a variety of sandwiches, wraps, and even flatbreads. The press quickly became the centerpiece of their kitchen, allowing them to offer a wider range of dishes with ease. The catering company’s reputation for creativity and reliability soared, and they were soon booking events months in advance.

A small, family-owned restaurant specializing in Mediterranean cuisine was looking for a way to add a unique touch to their menu. They decided to incorporate a variety of panini-style dishes, but their standard countertop press couldn’t keep up with the volume. They upgraded to an industrial panini press, which featured a larger cooking surface and adjustable pressure. This allowed them to offer a selection of sandwiches that were not only delicious but also visually appealing. The new press became a hit with customers, who raved about the restaurant’s ability to create gourmet sandwiches with a personal touch.

A busy sports bar was facing a challenge: their kitchen was small, and the staff was stretched thin. They needed a way to offer a variety of hot sandwiches without overwhelming the kitchen staff. An industrial panini press was the answer. The press’s ability to cook multiple sandwiches at once reduced the cooking time significantly, allowing the staff to focus on other tasks. The bar’s patrons were delighted with the speed and quality of the sandwiches, leading to increased sales and customer loyalty.

In a busy airport, a fast-food chain was looking to add a healthier option to their menu. They turned to an industrial panini press to create a variety of fresh, whole-grain sandwiches. The press’s even heat distribution ensured that the sandwiches were cooked to perfection, with a nice crust on the outside and a tender inside. The new menu item became a hit with travelers seeking a quick, nutritious meal, boosting the chain’s sales and customer satisfaction.

A gourmet food truck operator was on a quest to provide a unique dining experience. They chose an industrial panini press to cook a variety of artisanal sandwiches on the go. The press’s portability and ease of use made it an ideal choice for their mobile kitchen. The food truck’s patrons were thrilled with the quality and variety of sandwiches, leading to a loyal following and a successful business model.

These case studies illustrate the transformative impact that industrial panini presses can have on a business. From increasing efficiency and sales to enhancing the customer experience, these appliances have become a vital tool for businesses looking to stand out in the competitive foodservice industry. Whether it’s a café, catering company, restaurant, sports bar, fast-food chain, or gourmet food truck, the industrial panini press has proven to be a game-changer for those who are willing to embrace it.

In the ever-evolving culinary landscape, the future of sandwich making is a topic that’s both intriguing and promising. Experts in the field are buzzing about the potential impact of technology and innovation on the way we create and enjoy our favorite sandwiches. Let’s delve into what the industry experts have to say about the future of sandwich making.

The integration of automation and precision is a trend that’s picking up steam. With the advent of industrial panini presses, the art of sandwich making is becoming more systematic and consistent. Experts predict that this shift will lead to a new era of sandwich design, where the focus is not just on taste but also on presentation and health benefits.

One key aspect that industry experts highlight is the customization potential. Modern industrial presses allow for a level of customization that was once reserved for high-end restaurants. With adjustable heat settings and pressure controls, businesses can cater to diverse dietary preferences and restrictions, from gluten-free to vegan options.

The rise of healthy eating habits is reshaping the sandwich market. Experts note that as consumers become more health-conscious, the demand for fresh, whole-grain breads and ingredients rich in fiber and protein is on the rise. Industrial presses are well-suited for these trends, as they can quickly and evenly toast artisanal breads and lock in the flavors of high-quality fillings.

The impact of technology on the sandwich-making process is undeniable. Industry experts are excited about the potential for smart presses that can be controlled remotely or through an app. These devices could offer real-time feedback on cooking temperatures and times, ensuring that every sandwich is cooked to perfection.

Sustainability is another factor that’s shaping the future of sandwich making. Experts are observing an increasing trend towards using eco-friendly materials in the construction of industrial presses. This includes presses made from recycled materials and those designed for easy disassembly and recycling at the end of their lifecycle.

The global nature of food culture is also influencing the sandwich industry. Experts believe that the fusion of international flavors will become more prevalent, with a blend of local and international ingredients that appeal to a broader audience. Industrial presses can play a crucial role in this fusion, allowing for the quick and consistent preparation of complex sandwich fillings that capture the essence of different cuisines.

In terms of market trends, experts foresee a growing demand for portable and compact industrial presses. These units are ideal for food trucks, pop-up shops, and even home use, offering the flexibility to serve sandwiches wherever the demand takes them.

As for the industry experts, their insights paint a picture of a sandwich-making landscape that is both technologically advanced and customer-centric. They envision a future where innovation continues to drive the industry, creating new opportunities for creativity and success.

The role of foodservice operators in this future cannot be overstated. Experts suggest that operators who invest in the right industrial panini presses will not only attract more customers but also position themselves as leaders in the industry. The ability to offer a high-quality, consistent, and customizable sandwich experience is what customers are seeking, and these presses are the key to delivering it.

In conclusion, the future of sandwich making, as predicted by industry experts, is a blend of technology, sustainability, health consciousness, and cultural fusion. It’s an exciting time to be part of the culinary world, and the industrial panini press is at the forefront of this revolution, promising a future that’s both innovative and delicious.

The industrial panini press has been making waves in the culinary scene, and for good reason. Its rise in popularity isn’t just a fleeting trend; it’s a testament to the evolving tastes and demands of consumers. As the market for these presses grows, it’s becoming clear that they’re not just another kitchen gadget but a pivotal tool for businesses looking to enhance their operations. Here are some insights into the consumer trends that are driving the surge in demand for industrial panini presses.

Customers are gravitating towards industrial panini presses for a variety of reasons. The convenience factor is significant, as these presses allow for the quick and consistent preparation of paninis, a favorite among both casual diners and food enthusiasts. The ability to toast, melt cheese, and grill fillings simultaneously means that each sandwich is hot, crispy, and perfectly golden-brown on the outside while remaining tender on the inside.

Moreover, the customization options are vast. From selecting a range of bread types and fillings to controlling the temperature and pressure, industrial presses offer a level of control that manual cooking methods simply can’t match. This adaptability is appealing to consumers who want a sandwich that perfectly suits their taste preferences, whether they’re looking for a classic ham and cheese or something more exotic.

Another key factor is the hygiene aspect. With an industrial panini press, food preparation is more streamlined, reducing the risk of cross-contamination. This is particularly important for health-conscious consumers and those with allergies, who are more likely to seek out establishments that prioritize cleanliness.

The trend towards healthier eating habits is also playing a role. Industrial panini presses make it easy to create nutritious, low-carb options by using whole-grain breads and lean proteins. This aligns with the growing demand for balanced and wholesome meals, driving consumers to seek out places that offer such healthy choices.

Social media has a profound impact on consumer trends, and the rise of food-centric platforms like Instagram and TikTok has contributed to the popularity of industrial panini presses. High-quality images and videos showcasing perfectly pressed sandwiches are highly shareable, leading to a viral effect that further boosts demand.

Restaurants and cafes are recognizing the value of industrial panini presses in enhancing their menu offerings. These presses allow for the creation of visually appealing and delicious sandwiches that can serve as a signature dish. As a result, businesses that have invested in these presses are seeing an increase in foot traffic and repeat customers.

Additionally, the versatility of industrial panini presses isn’t limited to sandwiches. Many operators are using them to cook wraps, burgers, and even flatbreads, expanding their menu options without the need for additional cooking equipment. This flexibility is a huge draw for businesses looking to streamline their kitchens and reduce costs.

The demand for convenience is at an all-time high, and industrial panini presses are perfectly positioned to meet this need. With busy lifestyles and the rise of fast-casual dining, consumers are seeking quick, satisfying meals that can be enjoyed on the go. The efficiency and speed of industrial presses make them ideal for this market segment.

As the world continues to grapple with the effects of the pandemic, there’s a heightened appreciation for quick-service restaurants that can deliver high-quality food in a safe and efficient manner. Industrial panini presses offer just that, ensuring that food is prepared hygienically and served promptly.

The rise of food trucks and mobile catering services has also fueled the demand for industrial panini presses. These businesses often operate with limited space and resources, making the compact and versatile nature of industrial presses highly attractive. They provide a means to create high-quality sandwiches on the spot, appealing to event-goers and street food enthusiasts.

In conclusion, the popularity of industrial panini presses is a direct response to changing consumer trends. The convenience, customization, health consciousness, and the ability to meet the demand for fast, high-quality food have all contributed to their growing popularity. As consumers continue to seek out innovative and efficient food solutions, it’s clear that the industrial panini press is poised to remain a staple in the culinary landscape for years to come.