Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

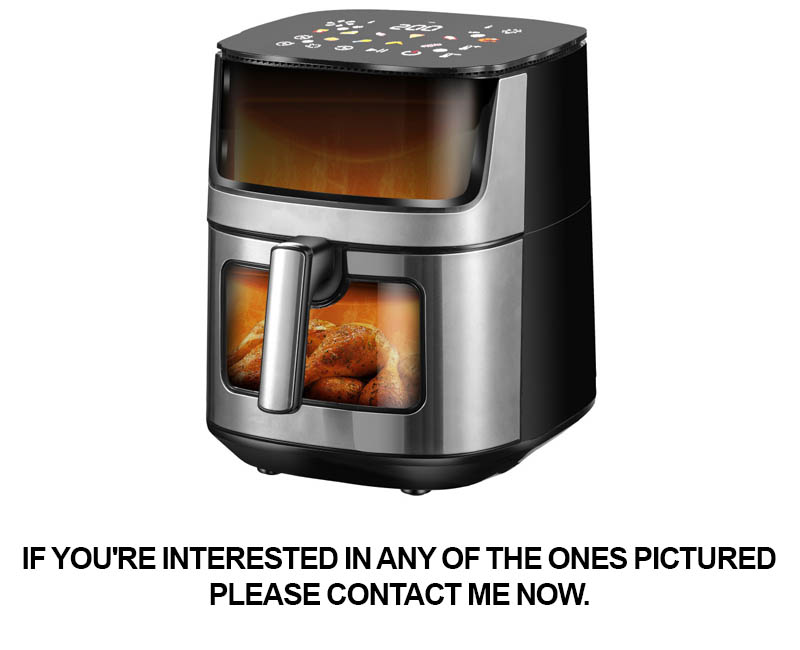

In today’s fast-paced and increasingly health-conscious world, the demand for innovative kitchen appliances has surged. Among these, air fryers have emerged as a game-changer, offering a healthier alternative to traditional frying methods. As the market continues to expand, the search for a reliable air fryer factory becomes crucial. In this article, we delve into the intricacies of finding such a factory, focusing on key aspects such as product quality, factory reputation, online reviews, industry standards compliance, and the art of negotiation and partnership building.

Air fryers have revolutionized the culinary landscape, becoming an indispensable appliance in modern kitchens around the world. These compact, innovative devices have transcended their initial perception as a mere novelty, evolving into a staple for health-conscious cooks and convenience-driven households alike. Let’s delve into the multifaceted role that air fryers play in shaping our contemporary kitchens.

At the heart of the air fryer’s rise to kitchen prominence is its ability to mimic the crispy texture of deep-fried foods with a fraction of the oil. This breakthrough has not only appealed to those seeking healthier alternatives to traditional frying methods but has also resonated with time-pressed cooks looking for a quick and easy way to prepare their favorite dishes. The air fryer’s technology involves circulating hot air at high speeds, which browns and seals the surface of the food without the need for excessive oil.

The health benefits of air frying are undeniable. Traditional frying methods often require copious amounts of oil, leading to a higher calorie count and increased risk of heart disease. Air fryers, on the other hand, use up to 80% less oil, making them a healthier option for those watching their fat intake. This shift towards healthier cooking has been a pivotal factor in the air fryer’s integration into modern kitchens.

Moreover, the versatility of air fryers has been a game-changer. Once limited to fried snacks, these appliances can now handle a variety of cooking tasks. From crispy fries and golden chicken wings to baked potatoes and even desserts, the air fryer’s capabilities have expanded to cover a wide range of culinary possibilities. This adaptability has made it a versatile tool for chefs and home cooks alike, who can experiment with different recipes and flavors.

In the realm of convenience, air fryers have set new standards. Their compact size and ease of use make them a space-saving addition to any kitchen. Preheating is a breeze, and the cooking process is often faster than traditional cooking methods. Additionally, the non-stick surfaces and easy-to-clean components mean less time spent on cleanup after cooking. This efficiency has made air fryers an attractive choice for busy individuals and families.

The environmental impact of cooking methods is also a significant factor in the popularity of air fryers. By reducing the amount of oil used, these appliances help to minimize waste and lower the carbon footprint associated with cooking. In an era where sustainability is a growing concern, the eco-friendly aspects of air fryers cannot be overlooked.

Moreover, the air fryer has become a symbol of culinary innovation. It has sparked creativity in the kitchen, encouraging chefs and home cooks to think outside the box. The ability to achieve a crispy texture without the traditional oil bath has led to the development of new recipes and cooking techniques. Chefs are now able to explore a broader spectrum of flavors and textures, pushing the boundaries of what can be achieved in a kitchen.

The social aspect of cooking has also been transformed by air fryers. They are often the centerpiece of gatherings, where friends and family can come together to prepare and enjoy a variety of dishes. The shared experience of cooking and sharing food is a cornerstone of many cultures, and the air fryer has become a catalyst for bringing people together around the table.

In summary, the role of air fryers in modern kitchens is multifaceted. They offer a healthier, more convenient, and versatile alternative to traditional cooking methods. With their eco-friendly benefits and ability to foster culinary innovation, air fryers have become an indispensable tool that not only enhances the cooking experience but also contributes to a more sustainable and connected world.

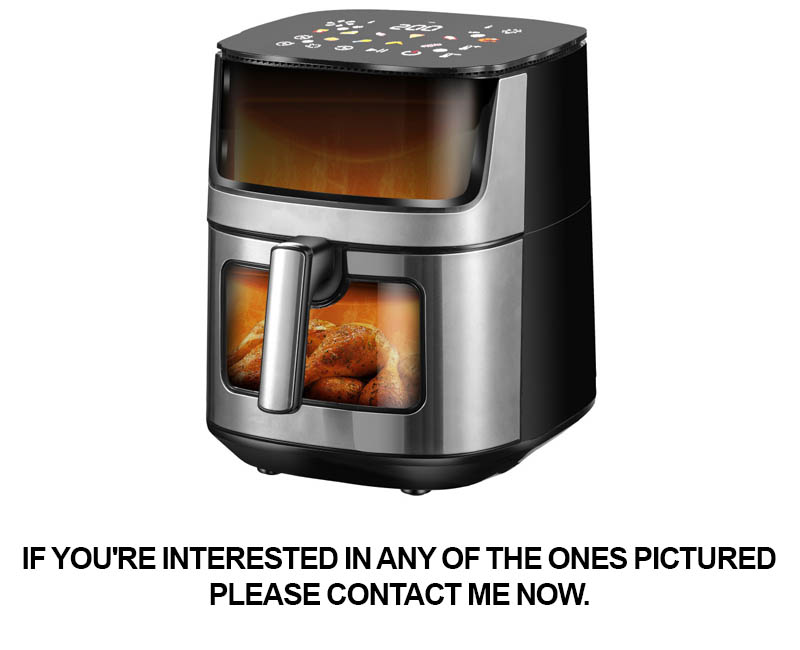

In the fast-paced world of kitchen appliances, the quality of a product is paramount, especially when it comes to air fryers. These modern cooking devices have revolutionized the way we think about healthy cooking, but their effectiveness and longevity rely heavily on the quality of their construction. Here’s a deeper dive into why product quality is so crucial for air fryers:

The foundation of a reliable air fryer lies in its materials. High-quality stainless steel, for instance, not only adds to the appliance’s durability but also ensures that it can withstand the rigors of everyday use. Plastic components, when used, should be BPA-free and resistant to heat and wear, guaranteeing that they won’t degrade over time and potentially leach harmful substances into the food.

The engineering behind an air fryer is equally important. A well-designed unit distributes heat evenly across the cooking chamber, which is essential for achieving a consistent and delicious outcome. The fan, heating element, and chamber must be meticulously aligned to ensure that the air circulates effectively, creating that crispy texture on the outside while keeping the inside tender and juicy.

The efficiency of an air fryer is also a testament to its quality. A superior air fryer uses less energy than traditional deep fryers, which not only saves money but also reduces the carbon footprint. Energy efficiency is not just about the bottom line; it’s about the future and the responsibility we have to our planet.

Durability is a critical aspect of quality that often goes unnoticed. Air fryers are subjected to high temperatures and frequent use, so their ability to withstand these conditions is paramount. The construction should include sturdy components that can handle the heat without warping or failing, ensuring that the air fryer will be a reliable kitchen companion for years to come.

Another quality to consider is the user experience. The ease of use, from assembly to cleaning, can greatly affect the overall satisfaction with the product. High-quality air fryers typically come with intuitive controls and a user-friendly interface. Features like a timer, temperature control, and automatic shut-off are not just conveniences; they are signs of thoughtful design that prioritize user safety and convenience.

The build quality extends beyond the physical components to include the design of the cooking chamber itself. A chamber with a non-stick coating that is both even and easy to clean is a clear sign of quality. The coating should be able to withstand the high temperatures without peeling or chipping, which can happen with cheaper, less durable coatings.

Safety features are another aspect of quality that should not be overlooked. A good air fryer will have an automatic shut-off feature that turns off the appliance if it’s left unattended or if the temperature exceeds a certain point. This not only protects the user from potential hazards but also prevents food from burning.

Innovation is also a key indicator of quality. Manufacturers that invest in research and development to create new features or improvements to existing models are likely to produce higher-quality products. Features like smart technology integration, where the air fryer can be controlled via a smartphone app, show that the manufacturer is committed to staying ahead of the curve and providing the best possible product.

Lastly, the brand’s commitment to customer service can be a reflection of the quality of their products. A reputable brand will stand behind their products with a solid warranty and excellent customer support. This not only shows that the manufacturer is confident in their product’s quality but also provides peace of mind to the consumer.

In summary, the quality of an air fryer is a multifaceted concept that encompasses materials, design, efficiency, durability, user experience, safety, innovation, and customer service. A high-quality air fryer is not just a tool for cooking; it’s an investment in a healthier lifestyle and a better culinary experience.

In the competitive world of kitchen appliances, the reputation of a factory can be the cornerstone of trust and reliability. When it comes to air fryers, a factory’s standing in the market can make all the difference. Here’s why reputation matters and how it shapes the product you receive.

The first thing that a reputable factory promises is consistency. A factory with a solid reputation is known for producing air fryers that consistently meet high standards. This means that every unit that rolls off the assembly line is expected to perform as advertised, without defects or performance issues. Consistency is crucial in a product that’s meant to last and to be used daily in kitchens around the globe.

Reputation also speaks to the quality of customer service. A factory with a good name will likely offer exceptional customer support, from pre-sales inquiries to after-sales service. This can include everything from helpful product information to prompt responses to any issues that arise. When you’re investing in a kitchen appliance, knowing that you have a reliable partner for support can be incredibly reassuring.

Word of mouth is a powerful tool, and a factory’s reputation is often built on the experiences of past customers. If an air fryer factory has a track record of satisfied customers, it’s a strong sign that their products are well-received and that they’ve managed to maintain a high level of quality over time. This kind of feedback can be invaluable in helping you make an informed decision.

Another aspect of reputation that can’t be overlooked is the factory’s adherence to industry standards and regulations. A factory with a good reputation will likely be certified by relevant authorities, ensuring that their products meet safety and quality benchmarks. This not only protects the consumer but also demonstrates the factory’s commitment to excellence.

When considering an air fryer factory’s reputation, it’s also important to look at the longevity of their brand. Factories that have been in business for many years are more likely to have a wealth of experience and expertise. They’ve weathered the industry’s ups and downs, and their continued success is a testament to their ability to adapt and innovate while maintaining a high standard of product quality.

The market is flooded with new entrants, but it’s the established factories with a strong reputation that have built a loyal customer base. These factories have earned their reputation by consistently delivering on their promises, and they understand that their customers’ satisfaction is key to their ongoing success.

Furthermore, a factory’s reputation can extend to their partnerships and collaborations. If they work with well-known brands or retailers, it’s an indication that their products are trusted and preferred. This kind of association can lend credibility to the factory’s offerings and can be a significant factor in the consumer’s purchase decision.

Transparency is another hallmark of a reputable factory. They are not afraid to showcase their manufacturing processes, quality control measures, and certifications. This openness allows potential customers to see for themselves the level of care and attention to detail that goes into their products.

Lastly, a factory’s reputation can be reflected in their approach to sustainability and ethical practices. A factory that is known for being socially responsible and environmentally conscious is likely to produce air fryers that are not only high-quality but also considerate of the planet. This kind of reputation can resonate with eco-conscious consumers who are looking for appliances that align with their values.

In conclusion, the reputation of an air fryer factory is a multifaceted indicator of the quality of their products. It encompasses consistency, customer service, customer feedback, compliance with industry standards, longevity, partnerships, transparency, and ethical practices. When you’re selecting an air fryer, the factory’s reputation should be a key factor in your decision-making process.

Navigating through the vast array of online reviews and testimonials can be a treasure trove of information for anyone looking to find a reliable air fryer factory. Here’s what to keep an eye out for:

In the realm of online reviews, it’s crucial to delve into the specifics. Look for comments that go beyond just “good” or “bad.” Users often share details about the product’s performance, durability, and ease of use. For instance, if an air fryer is praised for its even cooking and quiet operation, it might be a sign of high-quality engineering and craftsmanship.

The authenticity of reviews is paramount. Look for patterns in the comments. If multiple users report similar issues or experiences, it could indicate a recurring problem with the product. On the flip side, if there’s a consistent theme of satisfaction and positive feedback, it might suggest a reliable and reputable factory.

When it comes to testimonials, they often come from industry experts or influencers. These endorsements carry significant weight because they are not just based on one-time use but are usually the result of extensive testing and evaluation. Pay attention to the credibility of these individuals; are they known for their unbiased reviews, or do they have a history of promoting products without proper scrutiny?

The tone of the reviews and testimonials can also reveal a lot about the factory’s reputation. Look for a balance between positive and negative feedback. A factory that has a predominantly positive tone with a few scattered negative comments might be handling customer issues well, whereas a sea of negative reviews could be a red flag.

It’s not uncommon for customers to mention the customer service experience they had with the factory. This is particularly important because even the best products can face issues. How a company responds to customer concerns can speak volumes about their dedication to quality and customer satisfaction. Look for reviews that discuss how quickly and effectively the factory addressed any problems.

Reading through the dates of the reviews and testimonials is also key. Older reviews can tell you about the longevity of the product, while newer ones might highlight any recent improvements or issues. A steady stream of positive reviews over time can be a strong indicator of a factory’s consistent quality.

Keep in mind that the quantity of reviews and testimonials isn’t always a definitive measure of reliability. It’s the quality and consistency of the feedback that matter most. A factory with a large number of one-star reviews might have a few bad batches, but if the majority of feedback is positive, it’s likely that the factory is responsive to issues and works hard to rectify them.

Remember that reviews and testimonials are subjective. They are based on personal experiences and preferences. It’s important to take them as part of a larger picture. Consider the context of the review—was the air fryer used under ideal conditions, or were there external factors that could have affected performance?

Lastly, don’t just stick to one platform. Explore multiple review sites, social media, and forums to get a well-rounded view of the factory’s reputation. This cross-referencing can help you avoid biases and form a more accurate picture of the factory’s standing in the market.

By carefully examining online reviews and testimonials, you can uncover valuable insights into the quality and reliability of an air fryer factory. It’s a process that requires patience and attention to detail, but it’s well worth the effort to ensure that you’re partnering with a company that lives up to its promises.

Navigating the world of air fryer factories, one crucial step is to ensure the quality of the products you’re considering. The quality of products can be a deciding factor in the long-term success of your business, affecting everything from customer satisfaction to your brand’s reputation. Here’s a deep dive into what to look for when assessing the quality of air fryer products:

Materials UsedThe first thing to inspect is the materials. High-quality air fryers are often made with durable, food-grade materials. Check for stainless steel components, which are not only robust but also resistant to rust and corrosion. Plastic parts should be BPA-free and designed to withstand high temperatures.

Build QualityThe build quality of an air fryer is indicative of its longevity. Look for devices with sturdy construction, such as tight seams and a solid feel when held. Air fryers that are flimsy or have parts that creak or wobble may not stand up to regular use.

Performance FeaturesThe efficiency and functionality of the air fryer are crucial. Modern air fryers come with various features like adjustable temperature settings, timer controls, and sometimes even smart technology. Test these features to ensure they work smoothly and consistently.

Energy EfficiencyA high-quality air fryer should be energy-efficient, reducing utility costs while still delivering excellent performance. Check the energy consumption ratings and compare them with other models to find the most efficient option.

Safety FeaturesSafety should be a top priority. Look for air fryers with features like overheat protection, auto shut-off, and cool-touch handles. These features can prevent accidents and ensure peace of mind for both you and your customers.

Customer FeedbackReading reviews and testimonials can give you insights into the real-world performance of the air fryer. Pay attention to common complaints or compliments, as they can reveal patterns in the product’s quality.

Warranty and SupportA reliable factory stands behind its products with a solid warranty and excellent customer support. A comprehensive warranty indicates that the factory is confident in the quality of its air fryers. Additionally, good customer service can be a lifesaver if you encounter any issues post-purchase.

Innovation and DesignA quality air fryer often boasts innovative design features that enhance usability and convenience. Look for features like removable baskets for easy cleaning, digital displays for precise temperature control, and compact sizes for space-saving storage.

LongevityThe longevity of an air fryer is often a reflection of its quality. Check if the air fryer is designed to last, with parts that are easy to replace and a construction that can withstand the rigors of daily use.

Brand RecognitionLastly, consider the reputation of the brand. Established brands with a strong market presence are more likely to maintain high product quality. Their history and customer loyalty can serve as a testament to the reliability of their products.

In conclusion, when evaluating the quality of air fryer products from a factory, it’s essential to consider the materials, build quality, performance features, energy efficiency, safety, customer feedback, warranty, support, design, longevity, and brand recognition. Taking the time to thoroughly inspect these aspects can lead to a successful partnership with a factory that produces top-notch air fryers.

In the world of kitchen appliances, adhering to industry standards is non-negotiable. It’s not just about meeting legal requirements; it’s about ensuring that the products consumers purchase are safe, reliable, and of high quality. Let’s delve into the significance of industry standards compliance in the manufacturing process.

Ensuring SafetyThe primary reason for adhering to industry standards is to ensure the safety of the end-users. Standards like the UL (Underwriters Laboratories) certification in the United States or the CE (Conformité Européenne) mark in Europe are rigorous tests that appliances must pass to guarantee they are safe to use. These standards cover a range of safety aspects, from electrical safety to the materials used in construction, and even the durability of components.

Quality AssuranceCompliance with industry standards often involves a comprehensive quality assurance process. Factories that adhere to these standards are committed to maintaining a high level of quality control throughout their production line. This means that every aspect of the manufacturing process, from raw material sourcing to the final assembly, is monitored and controlled to meet the stringent requirements set by the respective standards.

Consumer TrustWhen a product carries a recognized industry standard mark, it serves as a trust signal to consumers. It tells them that the product has been evaluated by an independent third party and deemed to meet certain criteria. This trust is invaluable in a competitive market, where customers are increasingly looking for assurance that the products they buy are worth their investment.

Global Market AccessIndustry standards are not just about local regulations; they are also crucial for accessing international markets. Different countries have their own sets of standards, and products that do not comply with these standards may be denied entry or face additional hurdles. By ensuring compliance, manufacturers can expand their market reach and cater to a global customer base.

Technological InnovationIndustry standards often drive technological innovation. As manufacturers strive to meet these standards, they are encouraged to develop new materials, designs, and manufacturing techniques. This can lead to more efficient and sustainable production processes, as well as the creation of products that are more advanced and user-friendly.

Continuous ImprovementFactory compliance with industry standards is not a one-time achievement; it’s a continuous process. Regular audits and inspections are required to maintain certification, which means that manufacturers are constantly working to improve their products and processes. This commitment to ongoing improvement is a testament to the factory’s dedication to excellence.

Environmental ResponsibilityMany industry standards include environmental considerations. For instance, the ISO 14001 standard focuses on environmental management systems. Adhering to these standards ensures that the production process is environmentally friendly, reducing waste, emissions, and the overall carbon footprint.

Legal and Regulatory ComplianceCompliance with industry standards is not just about passing audits; it’s also about staying on the right side of the law. By adhering to these standards, factories avoid potential legal issues and fines that could arise from non-compliance.

Economic StabilityFactories that comply with industry standards often enjoy economic stability. They can rely on a steady stream of orders from customers who value quality and safety, and they can negotiate better terms with suppliers who also adhere to these standards.

Reputation and Brand ValueA factory’s reputation is built on its ability to consistently meet or exceed industry standards. This reputation is a valuable asset that enhances the brand’s value and can differentiate it from competitors in the eyes of both consumers and business partners.

In summary, industry standards compliance is a multifaceted process that touches on safety, quality, consumer trust, market access, innovation, and environmental responsibility. It’s a critical aspect of the manufacturing process that not only ensures the end product’s reliability but also supports the overall success and sustainability of the factory.

In the world of manufacturing, especially in the realm of kitchen appliances like air fryers, the implementation of rigorous quality control measures is paramount. These measures are the backbone of ensuring that the final product meets both the manufacturer’s standards and the expectations of the end-user. Here’s a delve into the various aspects of quality control that are critical in maintaining the reputation and reliability of a factory:

Consistent Raw Material SelectionThe journey of quality begins with the selection of raw materials. A reputable factory meticulously chooses materials that are not only of high quality but also meet specific industry requirements. This involves sourcing from trusted suppliers who adhere to strict quality standards, ensuring that the components used are free from defects and impurities.

Innovative Production TechniquesAdvanced production techniques are employed to minimize errors and maximize efficiency. Automation and precision machinery are used to ensure that each step in the manufacturing process is executed with the highest degree of accuracy. This includes cutting, welding, painting, and final assembly, all of which contribute to the overall quality of the air fryer.

Regular Equipment MaintenanceRegular maintenance of equipment is crucial to prevent breakdowns and maintain the integrity of the manufacturing process. A factory that takes pride in its quality control will have a schedule for routine checks and repairs. This proactive approach ensures that the machinery operates at peak performance, reducing the likelihood of defects in the final product.

Inspection Teams and TrainingSkilled inspection teams play a pivotal role in quality control. These teams are trained to identify any deviations from the standard specifications, no matter how small. They conduct thorough checks at various stages of production, from the initial assembly to the final product inspection. The knowledge and experience of these teams are invaluable in maintaining high standards.

Random Sampling and Statistical Process ControlRandom sampling is a common practice in quality control. By taking random samples from the production line, a factory can gauge the overall quality of its output. Statistical Process Control (SPC) is then used to analyze these samples, allowing for the early detection of any trends that might indicate a decline in quality. This data-driven approach helps in making informed decisions to correct any issues promptly.

Customer Feedback and Continuous ImprovementCustomer feedback is a goldmine of information for a factory aiming to improve its quality control measures. By actively seeking and analyzing customer feedback, a factory can identify areas where its products may fall short and take corrective actions. This continuous improvement cycle ensures that the factory is always striving to meet and exceed customer expectations.

Certifications and AuditsObtaining industry certifications is a testament to a factory’s commitment to quality. Regular audits by third-party organizations ensure that the factory adheres to these standards. These certifications, such as ISO 9001, ISO 14001, and ISO 45001, cover various aspects of quality management, environmental management, and occupational health and safety.

Documentation and TraceabilityDocumentation is key in quality control. A factory that values quality will have detailed records of every step in the production process. This includes specifications, manufacturing dates, inspection results, and any modifications made. Traceability allows for quick identification and rectification of any issues that may arise.

Environmental and Social ResponsibilityQuality control extends beyond the product itself. A responsible factory considers the environmental impact of its operations and the social welfare of its workforce. This includes using sustainable materials, minimizing waste, and ensuring safe working conditions. These practices contribute to the overall quality of the product and the factory’s reputation.

Collaboration with SuppliersThe quality of a product is not just the responsibility of the factory; it’s a collaborative effort. A factory that prioritizes quality will work closely with its suppliers to ensure that the components and materials meet the required standards. This collaboration helps in maintaining consistency and reducing the risk of defects.

Employee Involvement and EmpowermentEmployees are the backbone of any quality control system. A factory that invests in its employees through training and empowerment creates a culture of quality. When employees are engaged and understand the importance of their role in the quality process, they are more likely to contribute to the overall success of the factory.

By focusing on these quality control measures, a factory can ensure that each air fryer it produces is not just a functional appliance but a symbol of the factory’s dedication to excellence. This commitment to quality not only satisfies customers but also builds a strong foundation for long-term success and trust in the market.

Navigating the bustling aisles of a trade show or expo can feel like a treasure hunt for potential suppliers and partners. These events are a goldmine of opportunities, and understanding how to make the most of them can significantly impact your search for a reliable air fryer factory. Here’s what you need to know:

In the heart of these expansive venues, you’ll find booths and stands brimming with representatives from various factories and companies. Each one eager to showcase their products and services. It’s like a marketplace, but with a specific focus on the industry you’re interested in—air fryers and kitchen appliances.

Engaging with these representatives is key. Ask about their products, their factory’s capabilities, and their experience in the market. Don’t be afraid to delve into technical details or inquire about their supply chain. You’re there to gather as much information as possible to assess their reliability.

One of the most immediate benefits of attending trade shows is the chance to see products in person. The air fryers on display are often the latest models, giving you a firsthand look at their design, functionality, and build quality. This physical interaction can provide insights that photos or descriptions simply can’t.

Trade shows are also a great place to network. You’ll meet professionals from all corners of the industry, from designers and engineers to sales reps and distributors. These connections can lead to valuable partnerships, and sometimes, they can provide insider knowledge about which factories are reputable and which to avoid.

The atmosphere at trade shows is electric with potential. It’s a competitive environment, and companies are often willing to go the extra mile to stand out. This can mean offering special deals, exclusive samples, or even the chance to test products on the spot. Be ready to take advantage of these opportunities.

Remember, trade shows are not just about finding a factory; they’re about understanding the industry as a whole. Attend workshops and seminars to gain insights into the latest trends, technologies, and regulations. This knowledge can help you make informed decisions when evaluating potential suppliers.

Another crucial aspect is the opportunity to compare. At a trade show, you can easily move from one booth to another, comparing products, prices, and services. This side-by-side comparison can help you identify the strengths and weaknesses of each factory, allowing you to make a more educated choice.

Don’t underestimate the power of the trade show’s networking lounges and coffee breaks. These casual settings often lead to meaningful conversations that can extend beyond the show floor. You might find that a casual chat can turn into a long-term business relationship.

Lastly, be sure to gather all the information you can at the trade show. Take detailed notes, collect business cards, and snap photos of products and displays. These resources will be invaluable as you evaluate the factories you’ve met and decide which ones to pursue further.

In summary, trade shows and expos are more than just places to find suppliers. They are vibrant hubs of industry activity where you can see, touch, and talk to the people and products that shape the air fryer market. By engaging fully with the event, you can uncover a wealth of information and potential partnerships that will guide you in finding a reliable air fryer factory.

Navigating the culinary landscape, referrals and recommendations can be like finding a treasure map to the best air fryer factory. Word-of-mouth carries more weight than any advertisement, as it comes from the experiences of peers and colleagues in the industry. Here’s how to leverage these valuable resources:

Understanding the Value of a Personal TouchThe power of a referral lies in the personal connection. When someone in your network endorses a supplier, it’s often based on their firsthand experience and trust in the quality of the products and services provided. This personal touch can be invaluable in a market where reliability is key.

Seeking Out Industry InsidersTo tap into this network, it’s essential to connect with key players in your industry. Attend industry events, join trade associations, and participate in forums where professionals share insights and experiences. These platforms are where you’re likely to encounter referrals that have stood the test of time.

The Role of TestimonialsTestimonials are not just a collection of words but a story told by someone who has used the products or services of an air fryer factory. They provide a glimpse into the day-to-day operations, the reliability of the products, and the level of customer service offered. Look for detailed testimonials that offer specific examples of how the factory has met or exceeded expectations.

The Importance of a Referral’s BackgroundWhen considering a referral, it’s crucial to understand the background of the person giving it. Are they a respected figure in the industry? Have they been in the business for a significant amount of time? Their expertise and experience can give you confidence in the referral’s accuracy.

Verifying Referrals Through Diverse ChannelsDon’t rely on a single referral. Cross-reference the information with other sources. Check the factory’s profile on various industry platforms, read through their own testimonials, and look for any common threads in the feedback they receive. This will help you build a more comprehensive picture of the factory’s reputation.

The Power of a Good MatchA referral can lead you to a factory that specializes in the type of air fryers you need. However, it’s important to ensure that the factory’s offerings align with your specific requirements. Whether it’s about capacity, technology, or design, a good match can mean the difference between a successful partnership and a costly misstep.

Following Up on RecommendationsOnce you have a referral, it’s time to follow up. Reach out to the person who recommended the factory and ask for more details. Inquire about their specific experience, the challenges they faced, and how the factory addressed them. This direct interaction can provide clarity and insight.

Building Relationships Beyond the ReferralEven if the referral seems perfect, it’s wise to build a relationship with the factory on your own terms. Engage in conversations, ask for samples, and observe how they handle inquiries and issues. A strong relationship can turn a one-time transaction into a long-standing partnership.

Leveraging Recommendations for Continuous ImprovementOnce you’ve established a relationship with a factory through a referral, use that relationship as a springboard for continuous improvement. Share feedback with the factory, and be open to suggestions for enhancements. A good factory values customer input and is committed to evolving with the market.

Remember, a referral or recommendation is not just a name on a list; it’s a bridge to a world of potential. By carefully vetting and engaging with these referrals, you can uncover the hidden gems in the vast sea of air fryer factories and secure a reliable supplier that can meet your needs and exceed your expectations.

Navigating the ins and outs of business negotiations can be a delicate balance, especially when it comes to securing a deal with a supplier for air fryers. Here are some key strategies to consider when negotiating terms:

Understanding the Market ValueIt’s crucial to have a clear understanding of the market value for the air fryers you’re interested in. Research competitors’ pricing, consider the quality and features of the product, and take into account any additional costs such as shipping or customization. This knowledge allows you to enter negotiations with a realistic and informed perspective on what a fair price should be.

Setting Clear ObjectivesBefore diving into negotiations, define your objectives. Are you looking for the lowest price, the highest quality, or perhaps the fastest delivery times? Setting clear goals helps you stay focused and ensures that you don’t get sidetracked by less important details.

The Power of SilenceDuring negotiations, the art of silence can be a powerful tool. When you listen carefully and don’t rush to fill silences, it can encourage the other party to speak more, potentially revealing valuable information or weaknesses in their position that you can leverage.

Building RapportEstablishing a rapport with your negotiation counterpart can go a long way. When there’s a sense of mutual respect and understanding, it can be easier to find common ground. Remember to be friendly but professional, and find ways to connect on a personal level, whether it’s through shared industry experiences or mutual interests.

Flexibility and AlternativesBe prepared to offer alternatives or compromises. If you’re deadlocked on a certain term, consider what other aspects of the agreement you might be willing to adjust. This flexibility shows that you’re willing to work towards a mutually beneficial outcome.

The Art of the AskWhen it’s time to propose terms, be clear and direct. Start with the most important points for you and then move to less critical issues. It’s often effective to make a strong opening offer, which can leave room for negotiation while setting a high bar for the discussion.

Using the Right LanguageThe language you use can significantly impact the negotiation process. Avoid confrontational language and instead focus on collaborative terms. Phrases like “we understand your concerns” or “let’s find a solution that works for both of us” can foster a more positive atmosphere.

Understanding the Other Party’s NeedsTo negotiate effectively, you need to understand what the other party values. Is it price, delivery time, or perhaps after-sales service? Tailoring your negotiation strategy to address their priorities can help you reach a deal more quickly and effectively.

The Importance of DocumentationOnce you’ve reached an agreement, make sure it’s properly documented. This includes any verbal commitments, deadlines, and specific deliverables. A well-documented agreement can prevent misunderstandings and ensure that both parties are clear on the terms of the deal.

The Role of Legal RepresentationIn complex negotiations, especially those involving significant financial stakes, it’s wise to have legal representation. They can help ensure that all terms are legally sound and protect your interests in the event of any disputes.

Closing the DealWhen the terms are agreed upon, it’s time to close the deal. Be clear about the next steps, including any formal contracts that need to be signed and the timeline for implementation. A smooth closing process reflects well on both parties and sets the stage for a successful business relationship.

In the world of business, partnerships are the bedrock of sustainable growth and mutual success. Building a partnership with a supplier, especially in the competitive kitchen appliances industry, is akin to forging a strong alliance that can weather changes and drive innovation. Here are some insights into what it takes to cultivate a robust and fruitful business partnership.

Understanding the Supplier’s VisionTo build a partnership, it’s crucial to align your business goals with those of your supplier. Take the time to understand their long-term vision, mission, and values. This alignment ensures that both parties are moving in the same direction, fostering a sense of unity and shared purpose.

Open and Transparent CommunicationCommunication is the lifeblood of any partnership. Regular and open dialogue helps to iron out any misunderstandings, address concerns, and maintain a strong relationship. Be transparent about your needs, expectations, and any challenges you face. The same goes for the supplier; they should be able to share their production capabilities, timelines, and any potential issues without hesitation.

Mutual Respect and TrustRespect is a two-way street. Show your supplier that you value their expertise and contributions. Trust is built over time through consistent performance and reliability. When both parties respect each other’s expertise and trust the other’s intentions, the partnership can thrive.

Flexibility and AdaptabilityThe business landscape is ever-evolving, and a good partnership must be able to adapt. Be prepared to adjust your strategies and expectations as market conditions change. This flexibility also means being open to new ideas and solutions that might come from the supplier, which could lead to innovative products or improved processes.

Collaborative Problem-SolvingWhen challenges arise, a partnership is defined by how well the two parties work together to find solutions. Encourage a culture of collaboration where both sides are committed to overcoming obstacles. This could involve brainstorming sessions, shared research, or even bringing in external consultants to help address complex issues.

Investing in the RelationshipPartnerships require investment, both in time and resources. This means dedicating resources to support the supplier’s needs as well as your own. It could be as simple as providing feedback on their products or as significant as investing in new technology that can enhance their production capabilities.

Long-Term PlanningA strong partnership is built on long-term planning. Discuss and agree on a roadmap that outlines future goals, timelines, and milestones. This forward-thinking approach ensures that both parties are committed to the partnership’s growth and are working towards a common future.

Regular Reviews and AdjustmentsRegularly reviewing the partnership’s performance is essential. Set up periodic meetings to discuss progress, address any issues, and make necessary adjustments. This ensures that the partnership remains dynamic and responsive to changing market demands.

Cultural SensitivityIn today’s global marketplace, cultural sensitivity is key. Understanding and respecting cultural differences can prevent misunderstandings and foster a more harmonious working relationship. Be mindful of communication styles, business practices, and cultural norms.

Celebrating SuccessesRecognize and celebrate the successes of the partnership. Whether it’s the launch of a new product, meeting sales targets, or achieving a significant milestone, acknowledging these achievements can strengthen the bond between you and your supplier.

In conclusion, building a partnership is about creating a strong foundation of trust, communication, and mutual respect. It’s about being flexible and adaptable, investing in the relationship, and working collaboratively towards common goals. By nurturing these elements, a business partnership can become a powerful tool for growth and success in the kitchen appliances industry.