Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

As the world’s palate continues to evolve, the sandwich, once a humble street food staple, has transformed into a culinary canvas for both professional chefs and home cooks. This shift has fueled a demand for sophisticated kitchen appliances, leading to the rise of heavy-duty sandwich presses in industrial settings. These machines, once reserved for the bustling cafes and sandwich shops, have now found their way into the heart of home kitchens, revolutionizing the way we craft the perfect sandwich. In this exploration, we delve into the evolution of the sandwich press, the strength it brings to our beloved sandwiches, the innovative strides in heavy-duty sandwich press factories, and the global landscape that’s witnessing exporting powerhouses and emerging markets alike embracing this culinary marvel.

The Sandwich Revolution: From Street Food to Home Chef

In the bustling heart of city streets, the aroma of freshly grilled sandwiches wafts through the air, captivating passersby. Once a staple of fast food joints and street vendors, the sandwich has transcended its origins to become a culinary phenomenon that has made its way into the hearts and homes of food enthusiasts around the world. The evolution from a humble street food to a kitchen staple is a testament to the sandwich revolution.

Once considered a quick fix for a hearty meal, the sandwich has grown into a versatile canvas for culinary creativity. Chefs and home cooks alike are embracing this simple yet sophisticated dish, transforming it into a gourmet experience. The rise of gourmet sandwiches has sparked a renaissance in the art of sandwich making, pushing the boundaries of flavors and presentation.

The transformation from a street food to a home-cooked delicacy is not just a shift in preparation, but also in the appreciation of the sandwich as a culinary art form. Artisanal bread, premium ingredients, and meticulous attention to detail have become the new norm. Today’s sandwich is not just a meal, but a culinary adventure that tells a story of the chef’s skills and the eater’s palate.

The sandwich revolution has been fueled by several key factors. Firstly, the accessibility of high-quality ingredients has democratized gourmet sandwich making. No longer are exotic fillings and artisanal breads reserved for exclusive restaurants; they are now within reach of anyone with a passion for cooking.

Secondly, the rise of social media has played a pivotal role in this revolution. Chefs and home cooks alike share their sandwich creations online, inspiring others to experiment with flavors and techniques. Hashtags like #gourmet sandwiches and #homechef have become trending topics, showcasing the creativity and diversity of the sandwich world.

Thirdly, the convenience of modern life has led to a greater appreciation for quick yet satisfying meals. Sandwiches offer the perfect balance between convenience and taste, making them a perfect fit for busy lifestyles. Whether it’s a packed lunch for work or a post-workout snack, the sandwich has become a go-to choice for many.

The impact of the sandwich revolution can be seen in the proliferation of sandwich shops and food trucks offering a wide array of unique sandwiches. From traditional deli sandwiches to fusion creations that blend international flavors, the options are endless. These establishments have become social hubs, where people gather to share a meal and enjoy the company of friends and family.

Moreover, the rise of home delivery services has made it even easier for sandwich lovers to indulge in their favorite creations. With just a few clicks, customers can have gourmet sandwiches delivered to their doorstep, ensuring that the joy of gourmet sandwich making is not limited to those who can visit a brick-and-mortar shop.

In the home kitchen, the sandwich revolution is evident in the growing popularity of high-quality sandwich presses. These tools have become essential for achieving that perfect, golden-brown crust that is the hallmark of a great sandwich. From the classic flat press to the modern heavy-duty models, these appliances have become indispensable for any serious sandwich enthusiast.

The sandwich revolution has also had a profound impact on the culinary world. Chefs are now incorporating sandwich-making techniques into their fine dining menus, elevating the dish to a level of culinary respectability that was once reserved for more traditional fare. This has opened up new opportunities for chefs to showcase their creativity and push the boundaries of what a sandwich can be.

In conclusion, the sandwich revolution has transformed the humble sandwich from a quick bite on the go to a gourmet experience that can be enjoyed in the comfort of one’s own home. The evolution from street food to home chef reflects the changing landscape of culinary culture, where simplicity meets sophistication, and the joy of food is shared with friends and family.

The sandwich press has come a long way since its inception, evolving from a humble kitchen gadget to a symbol of culinary innovation. Initially, the humble origins of the sandwich press were simple and practical, born from the need to create evenly toasted sandwiches with a perfect golden crust. But as food culture evolved, so too did the sandwich press, transforming into a super-industrial tool that not only shapes sandwiches but also shapes the culinary landscape.

At its core, the sandwich press started as a straightforward mechanism—a flat surface with ridges to toast bread on the stovetop. This rudimentary design was easily replicated and quickly became a staple in households and eateries across the globe. It was a tool that allowed for the creation of simple yet satisfying sandwiches, perfect for a quick lunch or a hearty snack.

As the culinary world expanded, however, so did the possibilities for the sandwich press. Chefs began to experiment with different types of bread, fillings, and toppings, pushing the boundaries of what could be achieved with this simple kitchen appliance. The need for a more precise and versatile tool became apparent, and the sandwich press was ripe for an upgrade.

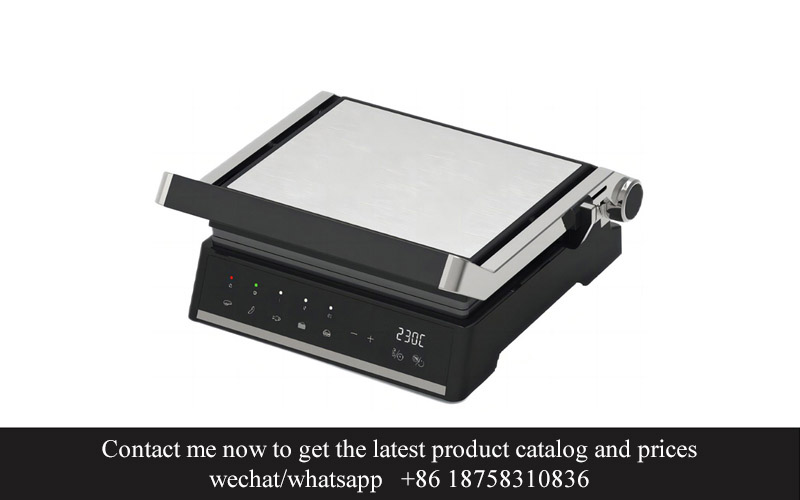

Enter the modern sandwich press, a far cry from its simple stove-top predecessor. These new appliances featured adjustable pressure plates that allowed for different levels of toasting, ensuring that each sandwich could be tailored to the individual’s preference. The non-stick surfaces and easy-to-clean designs made these presses not just for the kitchen but for any setting where sandwiches were king.

With the advent of commercial kitchens and the rise of fast-food chains, the demand for heavy-duty sandwich presses grew. These presses were engineered to withstand constant use, with reinforced metal components and heat-resistant coatings that could endure the rigors of a busy restaurant kitchen. They became an essential piece of equipment for anyone looking to serve a large volume of toasted sandwiches efficiently.

But the evolution of the sandwich press didn’t stop at commercial applications. As gourmet food culture took hold, sandwich presses were reimagined to accommodate a wider range of culinary creations. Artisanal sandwiches, filled with house-cured meats, freshly baked bread, and exotic toppings, required a sandwich press that could deliver both even toasting and structural integrity. The result was a press that not only toasted but also seared, with high-heat elements and innovative heating technology that ensured each sandwich was as much of a visual treat as it was a taste sensation.

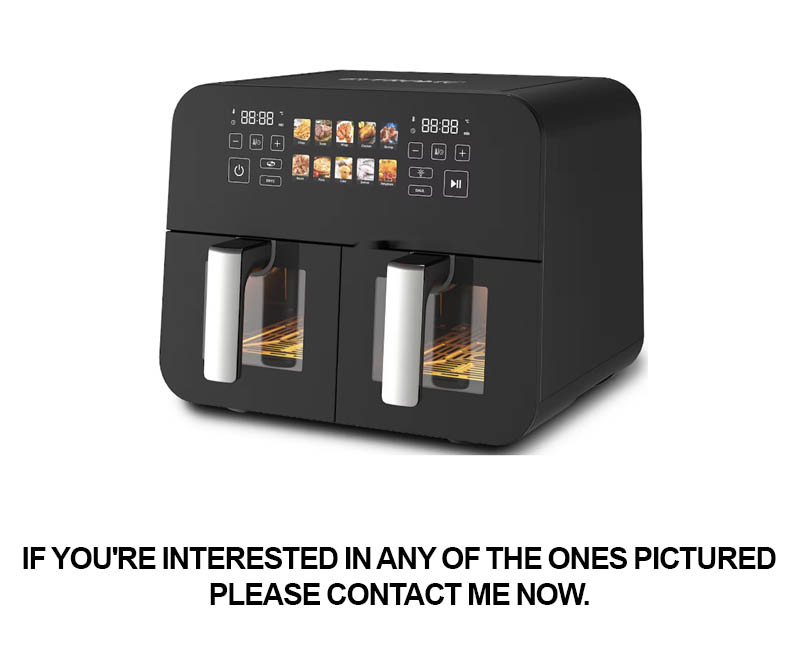

In the world of industrial food production, the sandwich press took on new life. Super-industrial sandwich presses were designed for massive output, with multiple compartments and automated feeding systems that could churn out thousands of sandwiches in a matter of hours. These presses were not just for toast; they could handle a variety of bread types, including brioche, sourdough, and even gluten-free options, catering to diverse dietary preferences.

As technology advanced, the sandwich press followed suit. Modern models are now equipped with smart controls, allowing for precise temperature and pressure settings that can be adjusted with a simple turn of a dial. Some models even come with integrated timers and digital displays, making them as user-friendly as they are effective.

The journey of the sandwich press from simple to super-industrial reflects the dynamic nature of culinary innovation. It’s a story of how a tool designed for practicality can evolve into a cornerstone of gourmet cuisine, all while remaining an essential component of the everyday meal. The sandwich press, once a humble kitchen utensil, has become a symbol of culinary progress and a testament to the endless possibilities that lie within the realm of foodservice.

In the world of culinary innovations, the heavy-duty sandwich press has emerged as a testament to the evolution of the humble sandwich from a simple street food to a gourmet dish cherished by home chefs. The journey of the sandwich press from its earliest iterations to the sophisticated, industrial-grade appliances of today is a story of necessity, innovation, and culinary ambition.

Once, a sandwich press was nothing more than a pair of flat surfaces that could be pressed together to cook bread to a golden brown with a satisfying crunch. These early devices were often made of cast iron and were heavy and cumbersome. They were more of a labor-intensive tool than a convenience, requiring significant effort to achieve that perfect sandwich texture.

However, as the popularity of sandwiches surged, especially in the 20th century, so did the demand for a more efficient way to cook them. This led to the first iterations of the heavy-duty sandwich press, which were designed to withstand the rigors of commercial use. These presses were constructed with thicker, sturdier materials and had larger surfaces to accommodate larger batches of sandwiches.

The transition from the simple to the super-industrial was marked by several key developments. First, the use of high-quality metals such as stainless steel became prevalent, ensuring durability and resistance to corrosion. This not only extended the life of the presses but also made them more hygienic, an essential factor in commercial kitchens.

Then came the introduction of adjustable heat settings. No longer was it a one-temperature-fits-all approach; chefs could now fine-tune the cooking process to their exact requirements, whether they were preparing a classic ham and cheese or an elaborate avocado toast with pesto.

The mechanical aspects of the heavy-duty sandwich press also saw advancements. Springs were incorporated to make opening and closing the press easier, reducing the physical exertion needed by kitchen staff. Additionally, the inclusion of non-stick coatings allowed for effortless food release, eliminating the need for constant oiling or buttering.

But it wasn’t just about mechanical improvements. The heavy-duty sandwich press became a symbol of culinary excellence. It allowed chefs to craft the perfect sandwich, with a crispy outer layer and a warm, melted cheese center. This precision was crucial in creating the signature sandwiches that have become beloved around the world, from the classic American grilled cheese to the delectable British full English.

As the sandwich press became a staple in both professional kitchens and home counters, its role in the culinary landscape expanded. It became an essential tool for food trucks, sandwich shops, and even catering services, capable of producing consistent, high-quality sandwiches at a rapid pace.

The heavy-duty sandwich press also played a part in the democratization of gourmet cuisine. It allowed anyone with a passion for cooking to replicate the same quality of sandwich as a professional chef. Home chefs could experiment with various fillings, toppings, and cooking techniques, all with the reliability of a heavy-duty press.

The evolution of the sandwich press didn’t stop there. Modern presses are not just about cooking sandwiches; they are about creating culinary experiences. Some models now come with additional features such as adjustable heat control, timers, and even built-in grills for those who want to incorporate more than just bread into their sandwich-making repertoire.

In conclusion, the heavy-duty sandwich press has transformed from a basic kitchen gadget to a powerful tool that defines the strength and quality behind the sandwich. It has stood the test of time, adapting to the changing needs of the culinary world, and ensuring that the joy of a perfectly cooked sandwich is accessible to everyone, from the bustling streets of a city to the cozy confines of a home kitchen.

In the world of culinary gadgets, the heavy-duty sandwich press has emerged as a symbol of both nostalgia and innovation. These presses, once a staple in home kitchens, have now evolved into robust, industrial-grade tools that cater to the demands of professional chefs and passionate home cooks alike. Let’s delve into the innovations that have transformed the heavy-duty sandwich press from a simple kitchen appliance to a powerhouse of culinary art.

The advent of high-quality materials has been a game-changer for heavy-duty sandwich presses. Modern presses are often crafted from stainless steel, which not only ensures durability but also adds a sleek, professional look to any kitchen. The use of thick, heavy-duty plates has replaced the lighter, more delicate designs of yesteryears, allowing for a superior pressing action that locks in flavors and ensures even cooking.

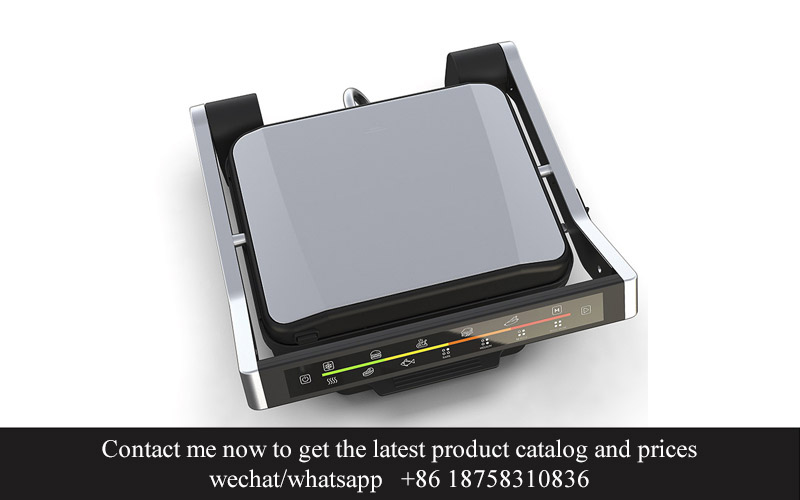

Smart features have become a hallmark of the latest heavy-duty sandwich presses. Integrated temperature controls allow users to precisely manage the heat, ensuring that each sandwich is cooked to perfection. Some models even come with digital displays that provide real-time feedback, making it easier to achieve the desired level of crispiness or doneness.

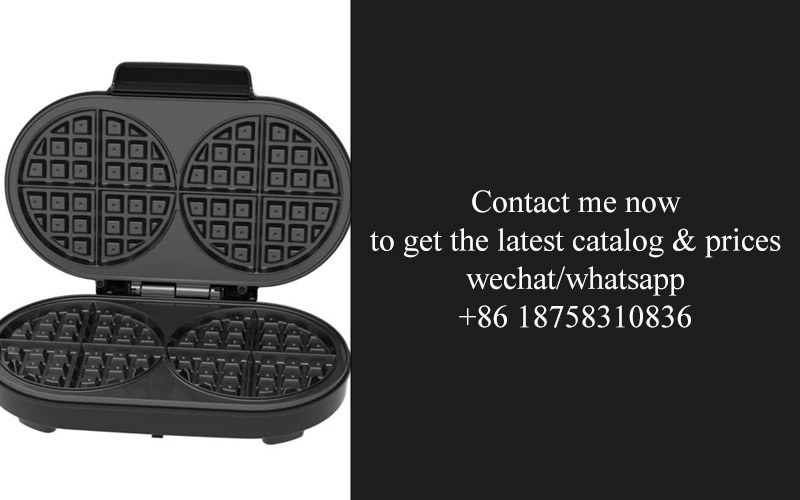

Customization has always been a key factor in the success of kitchen appliances, and heavy-duty sandwich presses are no exception. Factories now offer a variety of press sizes and shapes to accommodate different types of sandwiches, from classic ham and cheese to gourmet creations with multiple fillings. Some presses even feature adjustable pressure settings, allowing users to tailor the cooking process to their specific preferences.

The design of heavy-duty sandwich presses has also seen significant advancements. Many modern models come with non-stick surfaces that make cleaning a breeze, reducing the risk of food sticking and ensuring that every sandwich is released smoothly. The inclusion of ergonomic handles and lightweight construction means that these presses are not only powerful but also user-friendly, making them a joy to use for extended periods.

Safety features have been a priority in the development of heavy-duty sandwich presses. Locking mechanisms have been incorporated to prevent accidental openings during cooking, and some models are designed with heat-resistant materials that protect the user from burns. These features are particularly important in commercial settings where the risk of accidents is higher.

Energy efficiency has become a crucial aspect of appliance design, and heavy-duty sandwich presses are no different. Newer models are engineered to use less energy while still delivering the same level of performance, which is not only cost-effective for users but also environmentally friendly.

Innovation in the world of heavy-duty sandwich presses extends beyond the physical design and functionality. Factories are now exploring the use of sustainable materials and production methods, aiming to reduce their carbon footprint and contribute to a greener future. This commitment to sustainability is reflected in the use of recycled materials and energy-efficient manufacturing processes.

The integration of technology has also led to the creation of smart sandwich presses that can be controlled remotely. Chefs and home cooks can now program their presses to start cooking at a specific time, ensuring that their sandwiches are ready when they need them. This level of convenience is a testament to the evolving nature of kitchen appliances.

Lastly, the rise of the gourmet sandwich has spurred innovations in the design of heavy-duty sandwich presses. With the demand for unique and flavorful sandwiches growing, presses are being designed to handle a wider range of ingredients and cooking styles. This includes presses that can accommodate fillings like avocado, roasted vegetables, or even exotic meats, allowing for the creation of a diverse array of culinary masterpieces.

In conclusion, the evolution of the heavy-duty sandwich press from a simple kitchen gadget to a sophisticated culinary tool is a testament to the power of innovation. From the materials used to the features incorporated, these presses have become more than just appliances; they are essential tools for anyone looking to craft the perfect sandwich.

The market for heavy-duty sandwich presses has seen a surge in innovation, driven by changing consumer preferences and the ever-evolving landscape of the culinary world. Here’s a glimpse into the latest trends and insights shaping this niche sector.

The rise of the gourmet sandwich culture has not only elevated the status of the humble sandwich but has also spurred the development of specialized appliances. Consumers are now seeking not just any sandwich press but one that can deliver the perfect crunch and even cooking, every time.

Smart features are becoming increasingly common in heavy-duty sandwich presses. With the integration of digital controls and programmable settings, users can customize their cooking preferences, from temperature to pressing time. This level of personalization is a direct response to the demand for consistency and quality in home-baked sandwiches.

Health-conscious consumers are driving a shift towards healthier cooking options. Sandwich presses that offer non-stick surfaces and removable cooking plates are gaining popularity, as they make it easier to prepare sandwiches with minimal oil and fat. The emphasis on health has also led to an increase in eco-friendly materials used in sandwich press manufacturing.

The trend towards convenience is evident in the design of new heavy-duty sandwich presses. Compact and easy to store, these appliances cater to the busy lifestyle of modern consumers. The ability to quickly transform a simple slice of bread into a gourmet sandwich is a significant draw for those who value time-saving kitchen gadgets.

Customization isn’t just limited to the cooking process; it’s also about the variety of sandwiches one can create. Factories are now producing sandwich presses with interchangeable plates for different types of bread, from thick slices of sourdough to delicate ciabatta. This versatility allows for a wider range of flavors and textures in homemade sandwiches.

The market for heavy-duty sandwich presses is also being influenced by the growing popularity of home cooking shows and social media influencers. As these platforms showcase the art of sandwich making, more people are inspired to invest in high-quality appliances to replicate the professional results at home.

In terms of consumer insights, there’s a noticeable trend towards sustainability. Consumers are increasingly interested in the environmental impact of their purchases, and this extends to kitchen appliances. Sandwich press factories are responding by offering models that are not only durable but also made with sustainable materials.

E-commerce has played a pivotal role in the distribution of heavy-duty sandwich presses. Online marketplaces have made it easier for consumers to discover new brands and products, leading to a broader market reach. This digital transformation has also facilitated direct feedback from customers, allowing factories to quickly adapt to changing preferences.

Lastly, the integration of technology into kitchen appliances has opened up new possibilities. From touchscreens to Bluetooth connectivity, the future of heavy-duty sandwich presses looks to be even more interactive and user-friendly. As consumers continue to seek out the latest innovations, the market for these appliances is poised for further growth and evolution.

In the quest for the perfect sandwich, the role of heavy-duty sandwich press factories in quality assurance cannot be overstated. These factories are the backbone of the industry, ensuring that every sandwich press that leaves their facilities meets the highest standards of craftsmanship and performance. Here’s a closer look at how they uphold quality assurance:

The meticulous process of selecting materials is the cornerstone of quality assurance in heavy-duty sandwich press factories. High-grade stainless steel, known for its durability and resistance to corrosion, is often the preferred choice. These materials are not only robust but also maintain their integrity over time, ensuring consistent performance and longevity of the sandwich presses.

Precision engineering is another crucial aspect. The design and construction of a heavy-duty sandwich press require precision to ensure even heat distribution and pressure. Factories invest in advanced machinery and skilled technicians to craft components with exacting tolerances. This attention to detail minimizes the risk of uneven cooking and maximizes the sandwich-making experience.

Regular quality checks are conducted throughout the production process. Workers inspect each sandwich press for any defects or inconsistencies, from the initial stages of assembly to the final quality control inspection. This vigilant approach helps in identifying and rectifying issues before they can affect the end product.

Safety is paramount in heavy-duty sandwich press factories. Compliance with international safety standards is a non-negotiable requirement. Factories ensure that their products are free from sharp edges, properly insulated to prevent burns, and equipped with secure locking mechanisms to prevent accidents during operation.

The thermal performance of a sandwich press is a key indicator of its quality. Factories rigorously test the heat retention and distribution capabilities of their presses. This ensures that the sandwich is cooked to perfection, with a golden-brown crust and a melting interior. Consistent thermal performance is achieved through the use of high-quality heating elements and insulating materials.

Customer feedback is invaluable in the quality assurance process. Heavy-duty sandwich press factories often have a system in place to collect and analyze customer reviews. This feedback loop allows them to make continuous improvements and address any issues that may arise post-purchase.

Innovation is a driving force behind the quality assurance efforts of these factories. They are constantly exploring new technologies and materials to enhance the performance and functionality of their sandwich presses. This could include incorporating smart features like digital temperature controls or developing non-stick surfaces that simplify cleaning.

The environmental impact of manufacturing processes is also taken into account. Sustainable practices are adopted to minimize waste and reduce the carbon footprint. Factories may use energy-efficient machinery, recycle materials, and implement green packaging solutions to ensure that their quality assurance efforts are environmentally responsible.

The training of factory staff is a critical component of quality assurance. Employees are educated on the importance of their work and the impact it has on the final product. This training ensures that each worker understands the standards and procedures required to produce a high-quality sandwich press.

The packaging of the final product is another aspect that heavy-duty sandwich press factories pay close attention to. Secure and protective packaging is essential to prevent damage during shipping. This not only protects the product but also reflects the factory’s commitment to customer satisfaction.

In conclusion, the role of heavy-duty sandwich press factories in quality assurance is multifaceted. From selecting the right materials to ensuring safety, thermal performance, and customer satisfaction, these factories leave no stone unturned in their pursuit of excellence. Their dedication to quality is what sets them apart and guarantees that every sandwich press they produce is a testament to their commitment to perfection.

Eco-friendly designs have become a cornerstone in the manufacturing industry, and the heavy duty sandwich press factories are no exception. These designs are not just a trend; they are a reflection of the industry’s commitment to sustainability and responsibility. Here’s a closer look at the impact of these eco-conscious innovations:

The Sandwich Press Industry’s Shift Towards SustainabilityThe once-massive industrial machines used in heavy duty sandwich press factories have evolved to incorporate sustainable practices. These changes are more than skin-deep; they represent a holistic approach to reducing the environmental footprint.

Innovative Materials: A Greener ChoiceModern heavy duty sandwich press factories are turning to innovative materials that are not only durable but also environmentally friendly. From recycled stainless steel to bio-based plastics, materials that were once off-limits due to their durability are now being reevaluated for their eco-friendliness.

Energy Efficiency: Powering the FutureEnergy consumption is a major concern in any manufacturing setting, and heavy duty sandwich press factories are leading the charge in energy efficiency. By integrating smart technology and energy-saving features into their presses, these factories are cutting down on power consumption, thus reducing their carbon emissions.

Water Conservation: A Drop at a TimeWater usage is another critical factor in the manufacturing process. Advanced sandwich press machines are now equipped with systems that minimize water waste, whether it’s through closed-loop water systems or high-efficiency cleaning methods.

Waste Reduction: From Factory to ConsumerWaste management is a vital aspect of eco-friendly design. Heavy duty sandwich press factories are not just looking at reducing their own waste but also at the waste generated by their customers. By providing presses that reduce food waste and increase product yields, these factories are contributing to a circular economy.

Smart and Connected FactoriesThe integration of the Internet of Things (IoT) has allowed heavy duty sandwich press factories to monitor their operations in real-time, making adjustments to minimize energy and resource use. These smart factories are not only more efficient but also provide valuable data for ongoing improvements.

Employee Training and AwarenessEco-friendly designs are not just a product of technology; they require a culture shift. Factories are investing in training programs for their employees to understand the importance of sustainability and how to implement it in their daily work.

Community Engagement and PartnershipsHeavy duty sandwich press factories are not isolating themselves from the community. They are actively engaging with local organizations and partners to share best practices and collaborate on sustainability initiatives. This engagement goes beyond the factory walls and into the community.

Consumer Awareness and DemandThe consumer is increasingly aware of environmental issues and is willing to make choices that align with their values. Eco-friendly designs in heavy duty sandwich presses are not just a selling point; they are a response to consumer demand for sustainable products.

Certifications and ComplianceTo ensure that their products meet the highest eco-friendly standards, heavy duty sandwich press factories are seeking certifications and adhering to stringent regulations. These certifications validate the factory’s commitment to sustainability and provide consumers with confidence in the product’s environmental credentials.

Long-Term ViabilityThe impact of eco-friendly designs extends beyond immediate environmental benefits. By adopting sustainable practices, these factories are investing in their long-term viability, ensuring that they remain competitive and relevant in an industry that is increasingly scrutinized for its environmental impact.

In Conclusion, a Commitment to ChangeThe transformation of heavy duty sandwich press factories towards eco-friendly designs is a testament to the industry’s willingness to adapt and lead the charge in sustainability. It’s not just about making a sandwich; it’s about making a difference in the world.

In the ever-evolving world of kitchen appliances, the heavy-duty sandwich press has emerged as a cornerstone in the culinary landscape. From humble beginnings to cutting-edge technology, the journey of the sandwich press is a testament to innovation and adaptability. Here’s a closer look at the evolution of the sandwich press, from its simple roots to its current status as a super-industrial staple.

The early days of sandwich presses were quite basic. These devices were typically small, with flat surfaces and a hinge that allowed them to clamp down on bread, cheese, and fillings to create a perfectly toasted sandwich. They were often found in homes, but also in the kitchens of diners and cafes, where they became a symbol of quick, convenient food.

Over time, as the demand for sandwiches grew, so too did the sophistication of the sandwich press. Innovations such as adjustable heat settings and non-stick surfaces began to appear, making it easier for home cooks to achieve a perfect golden-brown crust. But it wasn’t until the rise of gourmet sandwiches that the sandwich press truly stepped into the spotlight.

The gourmet sandwich movement brought with it a newfound appreciation for the art of sandwich making. Chefs began experimenting with different types of bread, meats, cheeses, and condiments, pushing the boundaries of what a sandwich could be. This demand for high-quality, custom-made sandwiches required a more robust and versatile sandwich press.

Enter the heavy-duty sandwich press. These presses were designed to withstand the rigors of professional kitchens, where speed and consistency are paramount. They featured sturdy construction, durable materials, and often included features like adjustable pressure and temperature controls. These advancements made the heavy-duty sandwich press not just a tool, but a necessity for any kitchen aiming to serve gourmet sandwiches.

As the popularity of gourmet sandwiches continued to soar, so did the capabilities of the heavy-duty sandwich press. Today, these presses come with a range of innovative features that cater to both professional chefs and passionate home cooks. Here are some of the key innovations:

The market for heavy-duty sandwich presses has seen a surge in interest due to several trends. Consumers are increasingly looking for versatile kitchen appliances that can help them create a variety of dishes at home. Additionally, the demand for gourmet sandwiches has driven chefs to seek out the best equipment to deliver their culinary creations.

The impact of eco-friendly designs on the heavy-duty sandwich press industry is significant. As environmental concerns grow, manufacturers are responding by producing presses that are more energy-efficient and made from sustainable materials. This shift not only benefits the planet but also appeals to a consumer base that values sustainability.

In the global landscape, the heavy-duty sandwich press industry is witnessing a dynamic shift. Traditionally, Europe and the United States have been the leading markets for exporting these presses. However, emerging markets in Asia and Latin America are rapidly growing, offering new opportunities for heavy-duty sandwich press factories.

In Europe, the emphasis on gourmet food culture has been a driving force behind the demand for high-quality sandwich presses. The region’s established appliance markets have led to a strong export base, with many European factories exporting their products worldwide.

The United States, with its diverse culinary scene, has also become a significant player in the export market. The country’s large population and varied tastes have created a demand for a wide range of sandwich presses, from compact home models to commercial-grade equipment.

In Asia, particularly in countries like China and Japan, there’s a growing interest in Western-style cuisine, including gourmet sandwiches. This has opened up new markets for heavy-duty sandwich presses, as Asian consumers look to incorporate these appliances into their homes.

Latin America, with its burgeoning middle class and love for casual dining, is another region where the heavy-duty sandwich press is gaining traction. The demand for these presses is being fueled by the popularity of gourmet cafes and street food vendors who seek to offer a premium sandwich experience.

As the global landscape continues to evolve, heavy-duty sandwich press factories are adapting to meet the changing demands of international markets. They are investing in research and development to create products that not only meet the needs of professional chefs but also resonate with the values of eco-conscious consumers. The future of the heavy-duty sandwich press industry looks bright, with opportunities for growth and innovation on the horizon.

The relentless pursuit of the perfect sandwich has brought about a fascinating evolution in the culinary world. Sandwich presses, once a simple kitchen gadget, have now become sophisticated machines that are the cornerstone of sandwich perfection. As these heavy-duty sandwich presses emerge, they bring with them a story of transformation and innovation, reflecting the dynamic changes in consumer tastes and expectations. Here’s a glimpse into how these presses have become integral to the craft of making the ultimate sandwich.

The Sandwich Press’s Journey from Domestic to Industrial

In the early days, sandwich presses were mere tools, often seen in homes or at the humble beginnings of small eateries. Their designs were simple, focusing on even pressure and heat distribution to achieve a golden-brown crust on the bread. But as the demand for sandwiches grew, so did the need for a more robust and reliable tool. Heavy-duty sandwich presses started to appear, designed to withstand the rigors of high-volume operations in bustling cafes and sandwich shops.

The Shift to High-Quality Materials

One of the key developments in the evolution of the heavy-duty sandwich press is the shift towards high-quality materials. The days of aluminum or inexpensive stainless steel have given way to more durable options like commercial-grade aluminum, which can withstand the intense heat and pressure without bending or warping. Titanium and ceramic-coated surfaces have also emerged, offering superior heat retention and non-stick properties, ensuring that each sandwich is a work of art.

Advanced Technology Integration

As technology has advanced, so has the sandwich press. Modern heavy-duty presses now feature cutting-edge technology such as digital temperature controls, allowing for precise and consistent cooking temperatures. Some models even come with programmable settings that can cater to a variety of sandwich types, from classic ham and cheese to gourmet avocados and grilled vegetables. This technology integration not only improves the quality of the sandwich but also streamlines the cooking process for busy chefs.

Customization for Every Type of Sandwich

The versatility of heavy-duty sandwich presses has expanded to cater to a wide array of sandwich preferences. From the robust presses that can handle thick artisanal breads to those designed for delicate tortillas and pita breads, there’s a sandwich press for every style of cuisine. This customization has opened up new possibilities for sandwich shops, allowing them to experiment with ingredients and presentation, creating unique offerings that stand out in a competitive market.

The Art of Consistency and Uniformity

Consistency is the heartbeat of the sandwich-making industry, and heavy-duty presses play a crucial role in achieving it. With their ability to deliver uniform pressure and heat across the sandwich, these machines ensure that every sandwich is cooked to perfection. This uniformity is not just about appearance; it’s about taste and texture as well. The result is a high-quality product that can be reliably replicated time after time.

Quality Assurance in the Factory Setting

The role of heavy-duty sandwich press factories in quality assurance is undeniable. These factories adhere to strict quality control measures to ensure that each press leaving their facilities meets the highest standards. From rigorous testing of materials and components to ensuring that every machine undergoes a comprehensive inspection before shipment, the factories are committed to delivering products that are reliable, efficient, and long-lasting.

Sustainability and Eco-Friendly Practices

As the world becomes more environmentally conscious, eco-friendly designs have become a cornerstone of sandwich press manufacturing. These factories are increasingly incorporating sustainable practices, from using recycled materials in their production processes to designing machines that are energy-efficient. These eco-friendly designs not only reduce the carbon footprint but also set a precedent for sustainability in the industry.

Global Expansion and New Markets

The success of heavy-duty sandwich presses has led to a global expansion, with exporting powerhouses establishing a presence in markets worldwide. From the bustling streets of Europe to the vibrant cities of Asia and beyond, these presses are becoming a staple in sandwich shops, cafes, and restaurants. The emergence of new markets, particularly in emerging economies, is driving demand and innovation, as these regions embrace the sandwich culture and its sophisticated appliances.

In Conclusion

The journey of the heavy-duty sandwich press from a simple kitchen gadget to a key player in the culinary world is a testament to human ingenuity and the ever-evolving landscape of foodservice. Crafting the perfect sandwich, one factory at a time, these machines are not just tools; they are symbols of quality, consistency, and innovation. As the demand for gourmet sandwiches continues to grow, these factories will undoubtedly continue to evolve, pushing the boundaries of what’s possible in the sandwich-making process.