FOB Ningbo stands out as a leading air fryer supplier, offering innovative appliances that revolutionize cooking. With a strategic location in Ningbo, China, the company leverages its high-tech manufacturing heritage to produce energy-efficient, user-friendly air fryers. FOB Ningbo’s commitment to quality and innovation is evident in their range of versatile air fryers, designed to simplify healthy cooking while enhancing kitchen aesthetics. These compact, smart appliances cater to both residential and commercial needs, making them a must-have for anyone seeking a healthier, more convenient cooking experience.

In the ever-evolving kitchen appliance landscape, the rise of CE-EMC compliant 2200W appliances is revolutionizing cooking experiences. These high-powered devices offer precision, efficiency, and advanced technology, transforming the way we prepare meals. With sleek designs and smart features, these kitchen appliances not only enhance cooking performance but also integrate seamlessly into modern lifestyles. From energy-efficient ovens to multifunctional cooktops, the future of kitchen appliances is poised to blend power, convenience, and sustainability, catering to the diverse needs and preferences of today’s consumers.

The Moscow air fryer manufacturer has emerged as a leader in the kitchen appliance industry, offering a healthier alternative to traditional cooking methods. With a focus on innovation and sustainability, this company has developed a range of air fryers that are gaining popularity for their ability to create crispy, low-fat meals. Their air fryers, known for their sleek designs and advanced technology, have captured the attention of health-conscious consumers seeking convenient and eco-friendly cooking solutions. The Moscow air fryer manufacturer’s commitment to quality and customer satisfaction has solidified its position as a go-to choice for those looking to transform their culinary experiences.

In the ever-growing market for commercial air fryer appliances, the air fryer factory is at the forefront of innovation, transforming cooking with healthier, oil-reduced alternatives. These factories are driving technological advancements, focusing on energy efficiency and sustainable production practices. As the demand for air fryers surges, these facilities are embracing smart features and materials, ensuring that the next generation of air fryers not only meets the needs of health-conscious consumers but also sets new standards for cooking convenience and safety.

The restaurant-grade air fryer factory has revolutionized the cooking industry with its innovative appliances. These air fryers, once a home kitchen staple, have now become a game-changer in professional cuisine, offering a healthier, more sustainable cooking experience. By utilizing advanced technology to circulate hot air around food, these appliances achieve a crispy texture with significantly less oil, redefining traditional frying methods. The demand for these air fryers is soaring, driven by the health and wellness trend and their versatility in the kitchen, making them a must-have for any modern commercial kitchen.

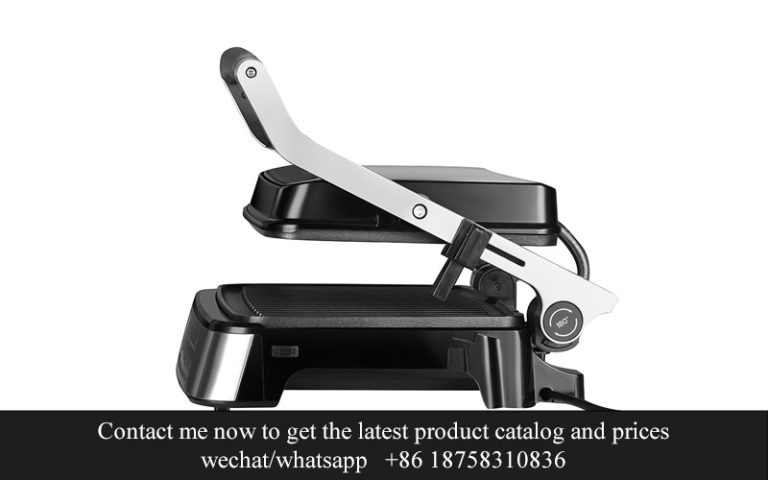

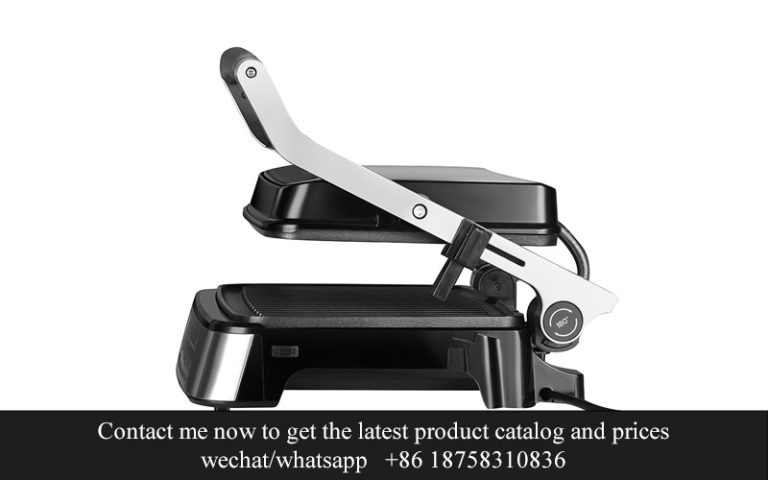

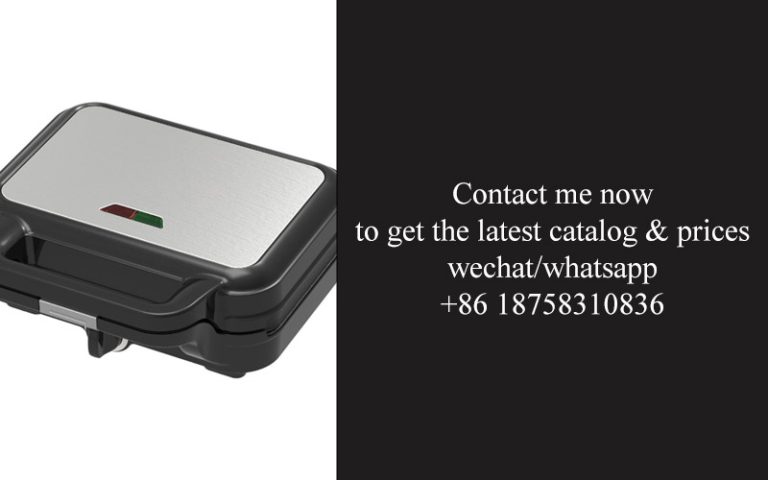

The evolution of the heavy-duty sandwich press factory has transformed the humble sandwich into a culinary masterpiece. These specialized appliances, designed for precision and consistency, ensure the perfect cooking experience. With their ability to lock in flavors and create that golden-brown crust, these presses have become an essential tool for achieving surefire results in the kitchen. As these factories continue to innovate, they are not just crafting the perfect sandwich; they are revolutionizing the way we cook and enjoy this beloved dish.

The continuous operation sandwich grill plant has revolutionized the food service industry with its technological advancements. These innovative facilities, designed for efficiency, utilize state-of-the-art grills and automated systems to ensure a seamless and rapid production process. By focusing on speed and quality, these plants have become the new standard in fast-casual dining, meeting the demand for fresh, high-quality sandwiches quickly. The integration of advanced technology in these grills has not only enhanced productivity but also ensured consistency and hygiene, making continuous operation sandwich grill plants a pivotal force in shaping the culinary landscape.

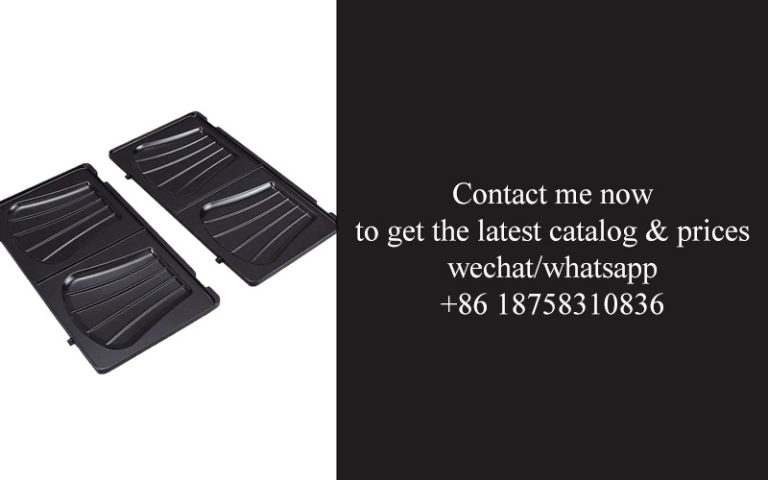

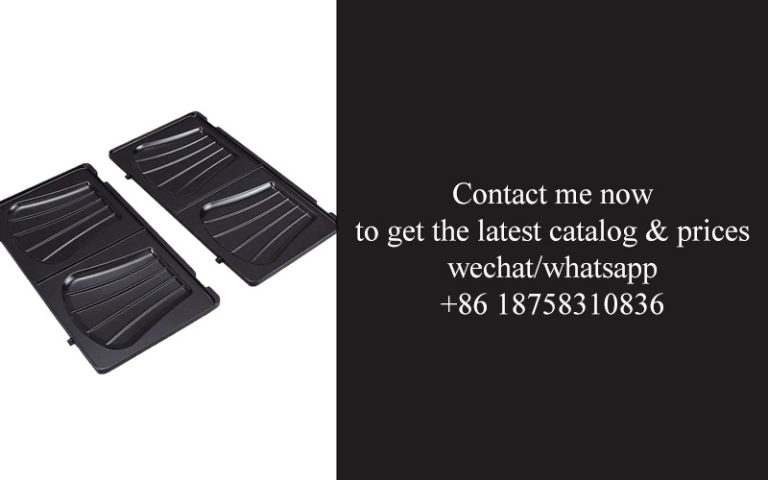

In the evolving kitchen appliance industry, integrated metal stamping for sandwich plates has revolutionized cooking efficiency and design. This advanced technology allows for the creation of robust, heat-resistant plates that enhance the performance of modern kitchen appliances. The sandwich plates, crafted with precision engineering, not only distribute heat evenly but also offer versatile surfaces for various cooking techniques. As kitchen appliances continue to evolve, the innovative use of integrated metal stamping for sandwich plates sets the stage for future trends, providing homeowners with efficient and stylish cooking solutions.

In the evolving grill industry, in-house mold making has become a pivotal factor for manufacturers aiming to enhance grill design and production efficiency. By integrating this capability, companies can produce unique, intricate features for grills, catering to diverse consumer preferences. This shift allows for quick prototyping and customization, reducing lead times and increasing responsiveness to market demands. In-house mold making not only fosters innovation but also ensures consistency in quality and durability, ultimately leading to more efficient and feature-rich grill products.

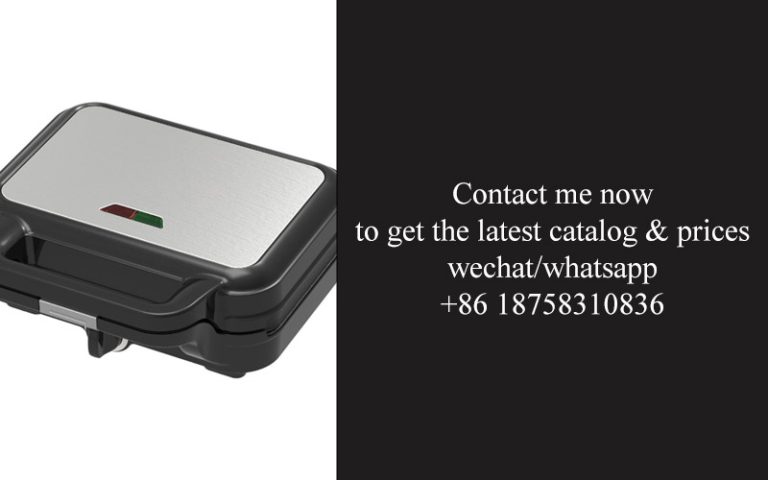

In the thriving food service industry, the UL certified commercial sandwich maker OEM stands as a beacon of efficiency and innovation. These specialized appliances boast a range of features, from advanced toasting technology and multiple sandwich compartments to non-stick surfaces and safety features, ensuring consistent quality and safety. Collaborating with a reputable OEM not only guarantees access to cutting-edge features but also streamlines operations and enhances the customer experience. By prioritizing quality, customization, and sustainability, these OEMs are pivotal in shaping the future of the sandwich-making landscape.