Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

Address

304 North Cardinal

St. Dorchester Center, MA 02124

Work Hours

Monday to Friday: 7AM - 7PM

Weekend: 10AM - 5PM

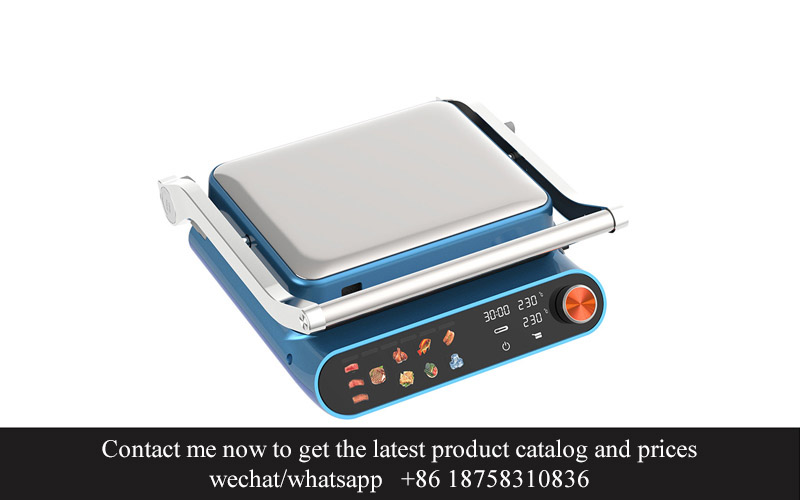

In a world where culinary trends are as diverse as the flavors they create, the kitchen has become a battleground for innovative appliances. Among these, the dual voltage sandwich press has emerged as a versatile tool that’s reshaping the landscape of home cooking. This article delves into the nuances of the 120V/240V sandwich press market, exploring its unique features, the importance of OEM partnerships, and the myriad benefits it offers consumers. We’ll also take a peek into the future of the sandwich press OEM space and how it’s poised to evolve. Join us as we uncover the dual voltage revolution in sandwich presses.

The dual voltage sandwich press market has emerged as a beacon of innovation in the culinary appliance industry. As consumers seek convenience and versatility in their kitchen gadgets, the dual voltage feature has become a sought-after innovation. This article delves into the intricacies of this market, exploring its growth trajectory, unique selling points, and the potential it holds for both manufacturers and consumers.

With the increasing globalization of food culture, there’s a growing demand for a wide range of cooking appliances that can cater to diverse voltage standards across the world. The dual voltage sandwich press addresses this need by offering compatibility with both 120V and 240V electrical systems. This adaptability makes it a prime candidate for OEMs looking to expand their product lines and meet international market demands.

The dual voltage sandwich press market is characterized by a blend of technological advancements and market trends. On one hand, there’s a push towards energy efficiency and eco-friendly designs. On the other hand, there’s a surge in demand for kitchen appliances that offer both functionality and style. This dual voltage sandwich press checks all these boxes, making it a compelling choice for OEMs to invest in.

One of the key factors driving the growth of the dual voltage sandwich press market is the rise of the modern, urban consumer. These individuals are often looking for appliances that not only perform well but also blend seamlessly into their kitchen decor. The dual voltage sandwich press, with its sleek design and versatility, is perfectly positioned to cater to this demographic.

In terms of innovation, the dual voltage sandwich press market is witnessing the integration of smart technology. From digital temperature controls to programmable settings, these appliances are becoming more sophisticated, offering users a tailored cooking experience. This technological integration is not just about convenience; it’s about empowering consumers to create the perfect sandwich every time.

For OEMs, the dual voltage sandwich press presents a unique opportunity to diversify their product offerings. By partnering with companies specializing in this niche, OEMs can tap into a market that is ripe for expansion. The potential for customization is vast, allowing OEMs to create sandwich presses that cater to specific regional tastes and preferences.

Moreover, the dual voltage sandwich press market is influenced by the rise of health-conscious consumers. As more people look for quick, nutritious meals, the sandwich has become a staple. The convenience of a sandwich press, especially one that can be used across different voltage systems, makes it an attractive option for those who are always on the go.

Another aspect of the dual voltage sandwich press market is its potential for international trade. Since these appliances are compatible with multiple voltage standards, they can easily be exported to various countries. This not only opens up new markets for OEMs but also creates a global network of consumers who appreciate the versatility of the product.

The market for dual voltage sandwich presses is also being shaped by the rise of e-commerce. Online platforms have made it easier for consumers to discover and purchase these appliances, regardless of their location. This has led to a more competitive market, with OEMs constantly seeking to innovate and differentiate their products to stand out.

In conclusion, the dual voltage sandwich press market is a dynamic and evolving sector within the culinary appliance industry. Its ability to cater to global voltage standards, combined with its innovative features and design, makes it a compelling product for OEMs to produce and consumers to enjoy. As the market continues to grow, it’s clear that the dual voltage sandwich press is not just a trend but a testament to the future of kitchen appliances.

The 120V/240V dual voltage sandwich press has emerged as a revolutionary product in the OEM sector, offering a versatile and adaptable solution for various markets. This innovative appliance is designed to cater to the diverse electrical standards across the globe, making it a sought-after choice for manufacturers looking to expand their reach and appeal.

With its ability to operate on both 120V and 240V power systems, the dual voltage sandwich press provides a seamless transition between different regions, ensuring that the same high-quality product can be enjoyed worldwide. This dual capability is not just a convenience; it’s a strategic advantage that allows OEMs to tap into new markets without the need for extensive redesigns or modifications.

The design of the 120V/240V sandwich press is meticulously crafted to maintain consistent performance regardless of the voltage. This means that bakers and food enthusiasts can achieve the perfect sandwich every time, with a level of precision that is often unattainable with single-voltage models. The pressure mechanism is finely tuned to ensure even cooking and a perfectly golden-brown crust, which is crucial for the sandwich-making experience.

In the OEM sector, the versatility of the dual voltage sandwich press is a significant draw. Original Equipment Manufacturers (OEMs) can now offer a product that is not only functional but also adaptable to the specific needs of their clients. This adaptability is particularly important in regions where electrical infrastructure varies greatly, such as in Europe, Asia, and North America.

The internal components of the dual voltage sandwich press are designed with quality and durability in mind. High-grade materials are used to withstand the demands of frequent use, ensuring that the appliance remains reliable over its lifespan. The heating elements are engineered to distribute heat evenly across the sandwich, preventing hot spots and cold areas that can affect the final product.

Another key feature of the 120V/240V sandwich press is its compact and space-saving design. This is especially beneficial for OEMs looking to integrate the appliance into a wider range of kitchen environments, from home kitchens to commercial settings. The sleek profile of the sandwich press allows for easy storage and placement on countertops or in limited spaces.

In terms of functionality, the dual voltage sandwich press often comes with a range of features that enhance the user experience. Non-stick surfaces make for easy cleaning and maintenance, while adjustable temperature controls allow users to customize their sandwich preparation to their liking. Some models even include safety features such as automatic shut-off to prevent overheating, ensuring peace of mind for both the user and the OEM.

From an OEM perspective, the dual voltage sandwich press also offers the opportunity to create custom branding and design options. This level of customization can be a major selling point for businesses looking to differentiate their products in a crowded market. OEMs can work closely with manufacturers to develop sandwich presses that align with their brand identity and customer expectations.

Moreover, the dual voltage sandwich press is an environmentally friendly choice. By reducing the need for multiple versions of the same product, OEMs can minimize waste and streamline their production processes. This eco-conscious approach is increasingly important to consumers and businesses alike, who are looking for sustainable and responsible products.

In conclusion, the 120V/240V dual voltage sandwich press has become a pivotal product in the OEM sector. Its dual voltage capability, high-quality construction, and user-friendly features make it an attractive option for manufacturers aiming to provide a versatile and reliable product to a global audience. As the demand for adaptable appliances continues to grow, the dual voltage sandwich press is poised to be a key player in shaping the future of the OEM market.

In the rapidly evolving kitchen appliances market, dual voltage sandwich presses have emerged as a significant trend, driving a new wave of innovation and consumer interest. This shift is not just a fad; it’s a strategic response to a multitude of market dynamics that are reshaping the OEM sector.

The globalization of consumer markets has led to a demand for appliances that are not confined to specific voltage standards. With dual voltage sandwich presses, manufacturers are catering to a diverse consumer base that spans across regions with differing electrical systems. This versatility allows for easier export and distribution, reducing the logistical challenges associated with single-voltage models.

The rise of health consciousness has also played a pivotal role. As consumers become more aware of the nutritional content in their meals, the convenience of making homemade sandwiches with fresh ingredients has become increasingly appealing. Dual voltage sandwich presses enable users to enjoy this trend regardless of their geographical location, further fueling market growth.

Moreover, the modern kitchen is all about efficiency and speed. Dual voltage sandwich presses offer the flexibility to cook at both standard 120V and higher 240V voltages, which can significantly reduce cooking times. This efficiency is particularly attractive to busy professionals and families who seek quick and hassle-free meal solutions.

Energy efficiency is another key factor. Modern consumers are increasingly looking for appliances that not only perform well but also minimize their carbon footprint. Dual voltage sandwich presses, by operating at different voltages, can optimize energy consumption based on the specific needs of the user and the local electrical grid, leading to more sustainable practices.

The integration of smart technology is also a driving force behind the popularity of dual voltage sandwich presses. OEMs are incorporating features like temperature control, timer settings, and even connectivity to mobile devices, allowing users to tailor their cooking experience and monitor it remotely. This technological advancement is a direct response to the growing consumer demand for smart kitchen appliances.

Additionally, the competitive landscape of the kitchen appliances industry is pushing OEMs to differentiate their products. Dual voltage sandwich presses offer a unique selling proposition that can set a brand apart from its competitors. As customers seek unique and innovative solutions for their kitchen needs, OEMs are leveraging the dual voltage feature to create a distinctive product offering.

Another factor to consider is the frequency of the electrical systems. Some regions use 50Hz while others use 60Hz, which can affect the performance of electrical appliances. Dual voltage sandwich presses eliminate these compatibility issues, making them universally adaptable and reliable in any kitchen setting.

Lastly, the cost-effectiveness of dual voltage sandwich presses cannot be overlooked. While they may have a higher upfront cost compared to single-voltage models, the long-term savings on energy consumption and the convenience they offer often outweigh the initial investment. This cost-effective approach aligns with the value-conscious consumer mindset, further propelling the dual voltage sandwich press market.

In summary, the market dynamics surrounding dual voltage sandwich presses are a complex interplay of global trends, consumer preferences, technological advancements, and competitive strategies. By addressing these dynamics, OEMs are not just adapting to market demands; they are leading the charge in shaping the future of kitchen appliance innovation.

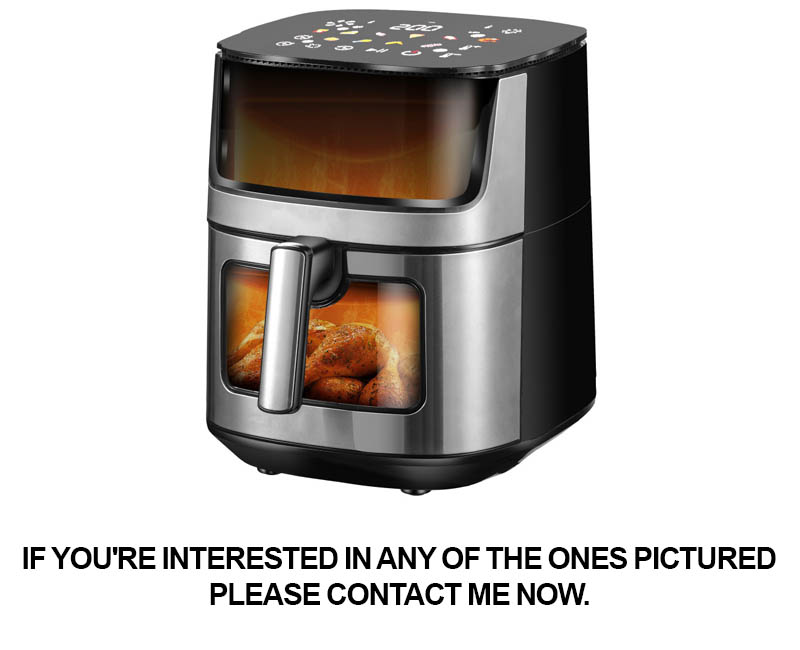

In the ever-evolving landscape of kitchen appliances, the sandwich press has found its place in the hearts and countertops of consumers worldwide. However, it’s not just the standard models that are making waves; it’s the innovative designs that are pushing the boundaries of what a sandwich press can be. Here’s a look into the future of sandwich presses, showcasing some of the cutting-edge designs that are shaping the market.

The sleek, modern aesthetic of the latest sandwich presses is a testament to the design revolution. With slim profiles and elegant lines, these presses are not just kitchen tools but also statement pieces. They come in various finishes, from brushed stainless steel to matte black, catering to a wide range of interior design preferences.

One standout feature in modern sandwich presses is the integration of smart technology. These appliances now include features like Bluetooth connectivity, allowing users to control the press remotely through their smartphones. Users can set the temperature, timer, and even receive notifications when their sandwich is ready to be enjoyed. This tech-forward approach is a game-changer for those who are both health-conscious and tech-savvy.

Functionality meets convenience with the introduction of non-stick surfaces that require minimal to no butter or oil for cooking. This innovation is not only health-friendly but also time-saving, as there’s no need for a thorough cleaning after each use. The non-stick coating is also durable, ensuring that the press can withstand the test of time and frequent use.

Safety is another critical aspect that has seen significant advancements. Modern sandwich presses come with features like automatic shut-off and overheat protection. These safety mechanisms are designed to prevent accidents and extend the life of the appliance. The inclusion of cool-touch handles and bases further ensures that users can safely handle the press even when it’s hot.

Designers are now focusing on user experience by creating presses that are easier to clean. The removable parts and the ability to cook a variety of sandwiches in one press, such as paninis, wraps, and even stuffed bread, have made these appliances versatile. The intuitive interfaces with LED displays and simple-to-read instructions have also made the cooking process more accessible to everyone, from seasoned chefs to kitchen novices.

The eco-friendly movement has also influenced the design of sandwich presses. Some models are now energy-efficient, consuming less power than their predecessors. This not only helps reduce utility bills but also contributes to a greener planet. The use of sustainable materials and recyclable components is another step towards a more sustainable future for kitchen appliances.

In the realm of innovation, sandwich presses are also experimenting with unique materials. Some models now incorporate ceramic plates, which are known for their ability to distribute heat evenly, ensuring a perfectly toasted sandwich every time. These materials not only enhance the cooking experience but also give the appliance a premium feel.

Moreover, the customization trend has extended to sandwich presses as well. Users can now choose from various press plates with different shapes and sizes, allowing them to create everything from classic sandwiches to creative open-face meals. The versatility of these plates is a hit with food enthusiasts who love to experiment with different recipes and flavors.

Lastly, the concept of the “sandwich press” itself is expanding. New designs are incorporating elements of the waffle iron, panini press, and even the toaster oven, creating multi-functional kitchen gadgets that can perform a variety of tasks. This consolidation of functions is a response to the consumer’s desire for space-saving appliances that can handle multiple cooking tasks.

As we delve into the future of sandwich presses, it’s clear that innovation is at the forefront. From smart technology to eco-friendly designs, the sandwich press is no longer just a kitchen tool—it’s a reflection of our changing culinary habits and values. The possibilities are endless, and the next generation of sandwich presses promises to be more versatile, user-friendly, and stylish than ever before.

In the ever-evolving landscape of the kitchen appliances industry, the role of Original Equipment Manufacturers (OEMs) in the production of dual voltage sandwich presses cannot be overstated. These partnerships are not just about manufacturing; they are about innovation, market adaptation, and strategic growth. Let’s delve into why these alliances are pivotal for manufacturers in the dual voltage sandwich press sector.

The integration of technology and design in the kitchen has led to a surge in demand for appliances that offer versatility and convenience. OEM partnerships allow manufacturers to tap into a wealth of expertise and resources that can drive the development of cutting-edge sandwich presses. Collaborating with OEMs means accessing state-of-the-art manufacturing processes, which can lead to products that are not only efficient but also eco-friendly.

Customization is key in today’s market, and OEMs excel in providing tailored solutions. For dual voltage sandwich press manufacturers, this means creating products that cater to diverse international markets, each with its unique electrical standards. By working with OEMs, these manufacturers can ensure that their products are compatible with both 120V and 240V power supplies, making them universally appealing.

Innovation is not just about creating new products; it’s about understanding consumer needs and anticipating future trends. OEM partnerships enable manufacturers to stay ahead of the curve by integrating the latest features and technologies into their sandwich presses. From touchless controls to smart connectivity, these collaborations foster a culture of continuous improvement that benefits both the manufacturer and the end-user.

The global nature of the kitchen appliances market requires manufacturers to navigate complex supply chains and regulatory landscapes. OEMs often have a global footprint, with established networks that can simplify the process of bringing dual voltage sandwich presses to market. This includes managing certifications, compliance, and distribution, which can be a significant hurdle for smaller manufacturers to overcome alone.

Quality assurance is another critical aspect where OEM partnerships shine. These collaborations often involve rigorous testing and quality control measures that ensure the sandwich presses meet or exceed industry standards. This not only builds consumer trust but also reduces the risk of product recalls and warranty claims, which can be costly and damaging to a brand’s reputation.

Collaborating with OEMs also allows manufacturers to focus on their core competencies. By outsourcing certain aspects of the production process, such as mechanical design or electrical engineering, manufacturers can allocate more resources to marketing, sales, and customer service. This strategic focus can lead to a more agile and responsive business model.

Innovation in materials and construction is another area where OEM partnerships can make a significant impact. The use of advanced materials like stainless steel, non-stick coatings, and durable plastics can enhance the lifespan and performance of sandwich presses. OEMs can source these materials and incorporate them into the design, ensuring that the final product is not only functional but also visually appealing.

Moreover, OEM partnerships can facilitate the adoption of sustainable practices. As consumers become more environmentally conscious, manufacturers need to demonstrate their commitment to sustainability. OEMs can help by integrating eco-friendly materials and manufacturing processes, as well as by providing guidance on recycling and disposal programs.

The competitive landscape of the kitchen appliances market is fierce, and differentiation is crucial. OEM partnerships can help manufacturers stand out by offering unique features that set their sandwich presses apart from the competition. Whether it’s a sleek design, innovative heating elements, or smart features that enhance user experience, these collaborations can provide the competitive edge needed to capture market share.

In conclusion, the importance of OEM partnerships for dual voltage sandwich press manufacturers cannot be underestimated. These alliances offer a wealth of benefits, from technological innovation and market adaptation to quality assurance and sustainable practices. By leveraging the expertise and resources of OEMs, manufacturers can produce high-quality, market-ready products that meet the demands of a global consumer base. The synergy between OEMs and manufacturers is not just a partnership; it’s a catalyst for success in the dynamic world of kitchen appliances.

In the realm of sandwich presses, the 120V/240V models have emerged as a beacon of innovation, capturing the attention of both consumers and manufacturers alike. Let’s delve into some compelling success stories that showcase the impact of these versatile appliances.

The first story involves a small, family-owned bakery that was struggling to cater to the diverse electrical standards of its customers. By adopting a 120V/240V sandwich press, they were able to expand their market reach and serve customers in various regions without compromising on the quality of their sandwiches. The dual-voltage feature allowed the bakery to invest in a single machine that could be used globally, streamlining operations and reducing costs.

Another success tale comes from a popular food truck business. Known for their creative sandwiches, the owners were constantly on the move, often finding themselves in locations with different voltage requirements. The introduction of the 120V/240V sandwich press into their mobile kitchen transformed their operations. Not only did it ensure consistency in the quality of their sandwiches, but it also saved time and effort by eliminating the need to carry around multiple appliances for different power sources.

In a third instance, a large commercial kitchen faced the challenge of maintaining a high level of hygiene and efficiency. The traditional single-voltage sandwich presses they used were prone to overheating and breaking down, leading to frequent downtime. The switch to a 120V/240V model not only improved the reliability of their equipment but also reduced maintenance costs. The dual voltage feature meant that the presses could be safely and effectively used in different countries, without the risk of power surges or voltage fluctuations damaging the appliances.

A fourth success story revolves around a tech-savvy startup that wanted to revolutionize the at-home sandwich-making experience. They designed a high-end 120V/240V sandwich press with advanced features such as adjustable heat settings, non-stick surfaces, and a sleek design. The dual-voltage capability allowed the product to be sold across multiple markets, gaining them a global customer base. The startup’s innovative approach to the sandwich press market was met with enthusiastic responses, and their product quickly became a sought-after item among sandwich enthusiasts.

In a fifth example, a well-established restaurant chain sought to enhance their menu offerings by adding a variety of gourmet sandwiches. They faced the challenge of ensuring that their signature recipes were replicated consistently across all their locations, despite varying voltage conditions. By investing in 120V/240V sandwich presses, the chain was able to maintain uniformity in their products, regardless of the power source. The dual voltage feature was a game-changer for them, allowing them to focus on their culinary excellence without worrying about equipment reliability.

A sixth story involves a retail chain that specializes in health-conscious food options. They noticed a growing demand for sandwiches that could be customized by the customer. The introduction of a 120V/240V sandwich press into their stores allowed customers to create their own healthy sandwiches with a variety of toppings and fillings. The dual voltage feature was crucial in ensuring that the presses worked efficiently in all locations, providing a seamless and satisfying customer experience.

In a seventh success, a food truck festival organizer wanted to create a unique culinary experience for attendees. They invited several food truck vendors to showcase their signature sandwiches using 120V/240V sandwich presses. The dual voltage capability of these presses ensured that each truck could operate without issues, regardless of the festival’s location. The result was a vibrant and diverse array of sandwiches that delighted festival-goers and generated positive word-of-mouth for the participating vendors.

A final story comes from a professional chef who was invited to participate in an international cooking competition. He faced the challenge of adapting his signature recipes to the different voltage standards of the host country. By using a 120V/240V sandwich press, he was able to recreate his dishes with the same precision and flavor profile as he would in his own kitchen. The versatility of the dual voltage sandwich press was a crucial factor in his victory, showcasing the appliance’s global appeal and culinary adaptability.

These success stories highlight the significant impact that 120V/240V sandwich presses have had on various businesses and culinary endeavors. From bakeries and food trucks to commercial kitchens and retail chains, the dual voltage feature has become an indispensable tool for ensuring consistency, efficiency, and satisfaction in the sandwich-making industry.

In today’s fast-paced world, convenience and versatility are key factors in the kitchen appliances market. Dual voltage sandwich presses have emerged as a standout product, offering consumers a range of benefits that cater to diverse needs and preferences. Here’s a closer look at the advantages these innovative appliances bring to the consumer market.

Universal CompatibilityOne of the standout benefits of dual voltage sandwich presses is their universal compatibility. With the ability to operate on both 120V and 240V power sources, these presses can be used almost anywhere in the world. This feature is particularly appealing for travelers, expatriates, and anyone who frequently moves or travels with their appliances. It eliminates the need for voltage converters or transformers, ensuring a seamless cooking experience no matter where you are.

Consistent ResultsThe dual voltage capability of these sandwich presses ensures consistent results across different regions. Since the power output remains stable regardless of the voltage, users can enjoy the same quality of toasted sandwiches, paninis, and other pressed meals every time. This consistency is crucial for those who value the taste and texture of their food, as it guarantees that the sandwich press will deliver the same level of performance regardless of the power source.

Enhanced Safety FeaturesSafety is a top priority in kitchen appliances, and dual voltage sandwich presses do not compromise on this front. These appliances often come with features like automatic shut-off timers, non-slip bases, and cool-touch handles, which help prevent accidents and burns. The ability to operate on different voltages also means that the appliances are designed to handle varying electrical conditions, reducing the risk of overheating or electrical failures.

Eco-Friendly OperationConsumers who are environmentally conscious will appreciate the energy-efficient operation of dual voltage sandwich presses. By adjusting to the local power supply, these appliances can optimize their energy consumption, leading to lower electricity bills and a smaller carbon footprint. This eco-friendly aspect is a significant draw for those looking to make sustainable choices in their daily lives.

Customizable Cooking OptionsDual voltage sandwich presses often come with a variety of settings and features that allow for customizable cooking options. Users can adjust the temperature, pressure, and cooking time to suit their preferences and the type of sandwich they’re preparing. Whether you prefer a lightly toasted bagel or a well-done panini, these appliances offer the flexibility to cater to a wide range of tastes.

Ease of UseThe design of dual voltage sandwich presses is typically user-friendly, with intuitive controls and clear instructions. Many models come with removable non-stick plates, making cleaning a breeze. The compact size and portability of these appliances also make them convenient for small kitchens or for those who like to move their appliances from one location to another.

Brand Variety and CustomizationThe market for dual voltage sandwich presses is diverse, offering a wide range of brands and models. This variety allows consumers to choose an appliance that fits their budget, cooking style, and aesthetic preferences. Some brands even offer customization options, such as color choices or additional features, allowing users to tailor their sandwich press to their specific needs.

Longevity and DurabilityHigh-quality materials and robust construction ensure that dual voltage sandwich presses are built to last. These appliances are designed to withstand regular use and can be a long-term investment in a kitchen. The durability of these appliances is a significant benefit for consumers who want a reliable and long-lasting kitchen tool.

Innovation in DesignThe design of dual voltage sandwich presses is not just about functionality; it’s also about innovation. Brands are constantly pushing the boundaries with sleeker designs, advanced heating elements, and smart features that make cooking more enjoyable and efficient. This focus on innovation means that consumers are getting more than just a sandwich press; they’re getting a piece of technology that enhances their culinary experience.

Community and SupportManufacturers of dual voltage sandwich presses often have strong communities and support systems. From online forums to customer service hotlines, consumers have access to resources that can help them troubleshoot issues, share recipes, and stay connected with other users. This sense of community can be incredibly valuable, especially for those who are new to using these types of appliances.

In conclusion, the benefits of dual voltage sandwich presses for consumers are multifaceted. From universal compatibility and consistent results to enhanced safety features and eco-friendly operation, these appliances offer a compelling package that caters to the modern consumer’s needs. As technology continues to evolve, we can expect even more innovative features and design improvements that will further enhance the value and appeal of dual voltage sandwich presses in the marketplace.

In the evolving landscape of the OEM sandwich press market, several industry trends are shaping the future of dual voltage appliances. From advancements in technology to shifting consumer preferences, these trends are pivotal for manufacturers looking to stay ahead in the competitive sandwich press OEM space.

Technological IntegrationModern sandwich presses are not just kitchen gadgets; they are integrated into a broader culinary experience. The next wave of innovation involves incorporating smart technology, such as Bluetooth connectivity and app integration. This allows users to control their sandwich press remotely, customize settings, and even monitor cooking times through their smartphones.

Sustainability FocusWith growing environmental concerns, sustainability is becoming a significant factor in product development. Dual voltage sandwich presses that are energy-efficient and made from recycled materials are likely to gain popularity. OEM manufacturers are exploring eco-friendly designs that not only appeal to environmentally conscious consumers but also contribute to a more sustainable supply chain.

Global Market ExpansionThe demand for dual voltage sandwich presses is not confined to any single region. As global travel becomes more frequent, consumers in various countries are looking for appliances that can operate in different voltage systems. OEM manufacturers are responding by producing models that cater to a global audience, ensuring compatibility and convenience for international customers.

Customization and PersonalizationCustomization is no longer a niche market trend; it’s becoming a standard feature. OEMs are focusing on creating sandwich presses that can be customized in terms of size, shape, and even materials. Personalization extends beyond aesthetics to functionality, with users being able to choose from a range of attachments and features that cater to their specific cooking preferences.

Health and Wellness IntegrationAs the health and wellness movement gains momentum, the OEM sandwich press market is responding by offering models that promote healthier eating habits. This includes features like adjustable heat settings to control the level of browning and the inclusion of non-stick surfaces that reduce the need for excessive oil. These innovations cater to consumers who are looking for convenient ways to prepare nutritious meals at home.

Smart Cooking TechnologyThe rise of smart cooking technology is transforming the way appliances are designed and used. OEM sandwich presses are being developed with built-in sensors that can detect when the sandwich is perfectly toasted to the desired crispness. These smart features not only improve the cooking experience but also save energy by avoiding overcooking.

Regulatory ComplianceNavigating the complex web of international electrical safety standards is a challenge for OEM manufacturers. The next wave of innovation will see a focus on compliance with various global regulations, ensuring that dual voltage sandwich presses meet safety requirements in every market they are sold.

Innovative MaterialsThe materials used in sandwich presses are undergoing a transformation. Lightweight, durable materials that can withstand high temperatures without warping or releasing harmful substances are being explored. This not only makes the appliances more reliable but also contributes to a reduction in the overall carbon footprint.

E-commerce InfluenceThe rise of e-commerce has changed the way consumers purchase appliances. OEM sandwich press manufacturers are adapting by creating products that are not only visually appealing but also optimized for online shopping experiences. This includes clear, detailed product descriptions, high-quality images, and easy-to-navigate websites that make the purchasing process seamless.

Collaborations and PartnershipsTo stay competitive, OEM sandwich press manufacturers are seeking out strategic collaborations and partnerships. This includes working with culinary experts to develop unique sandwich recipes that can be shared with customers, as well as forming alliances with material suppliers to source innovative and sustainable materials.

In conclusion, the sandwich press OEM space is poised for significant advancements driven by technological integration, sustainability, global market demands, customization, health consciousness, smart cooking features, regulatory compliance, innovative materials, e-commerce trends, and strategic collaborations. As these trends continue to evolve, the future of the dual voltage sandwich press market looks promising, offering consumers a wider array of choices and a more tailored cooking experience.

In the ever-evolving landscape of kitchen appliances, the dual voltage sandwich press has emerged as a beacon of innovation, offering consumers a versatile and powerful tool for crafting the perfect sandwich. As we look back at the journey and forward to what lies ahead, it’s clear that the dual voltage revolution is not just a trend; it’s a game-changer. Here’s why embracing this innovation is crucial for the sandwich press industry.

The dual voltage sandwich press is a marvel of modern engineering, designed to operate seamlessly across different voltage standards, typically 120V and 240V. This capability makes it an ideal choice for international travelers, expatriates, and those living in regions where voltage norms vary. The adaptability of these presses has opened up new markets and opportunities, allowing manufacturers to cater to a global audience with a single product line.

One of the key benefits of dual voltage sandwich presses is their ability to maintain consistent performance across various regions. Unlike single-voltage models that might struggle to achieve optimal heat distribution or cooking times, dual voltage presses ensure that every sandwich is cooked to perfection, regardless of the electrical grid it’s plugged into. This consistency is a major draw for consumers who demand quality and reliability from their kitchen gadgets.

The rise of health-conscious consumers has also played a significant role in the popularity of dual voltage sandwich presses. As people seek to reduce their reliance on processed foods and fast food, they’re turning to home cooking as a healthier alternative. The convenience and efficiency of a sandwich press make it an attractive option for those looking to whip up a quick, nutritious meal. With the ability to customize fillings and cooking temperatures, these presses offer a level of control that’s hard to find in other kitchen appliances.

The success stories with 120V/240V sandwich presses are numerous. Take the case of a small startup that began producing dual voltage models and quickly expanded its customer base due to the appliance’s versatility. Another example is a large manufacturer that integrated smart technology into its dual voltage presses, offering users the ability to program their desired cooking times and temperatures. These innovations not only enhanced the user experience but also positioned the brand as a leader in the market.

For consumers, the benefits of dual voltage sandwich presses are multifaceted. The convenience of a single appliance that can be used worldwide is invaluable. Additionally, the ability to cook a variety of sandwiches, from classic ham and cheese to gourmet avocado and roasted red pepper, adds a layer of excitement to the daily meal prep routine. Moreover, the ease of use and clean-up, coupled with the compact size of these presses, make them a practical and space-saving addition to any kitchen.

In the realm of industry trends, the future of sandwich presses seems to be intertwined with technology. Smart features are becoming increasingly common, with some models now offering connectivity to smartphones and tablets, allowing users to monitor and control their cooking process remotely. This integration of technology is not just about convenience; it’s about empowering consumers to take control of their health and cooking experiences.

The rise of eco-friendly appliances is another trend that’s shaping the sandwich press OEM space. As consumers become more environmentally conscious, they’re looking for products that are not only efficient but also sustainable. Manufacturers are responding by producing dual voltage sandwich presses with energy-saving capabilities and recyclable materials, aligning with global sustainability goals.

The dual voltage revolution in sandwich presses is not just a shift in technology; it’s a shift in consumer expectations. As the industry continues to evolve, we can expect to see even more innovative designs, from presses with built-in toasters and grills to those that can be used for a variety of cooking tasks beyond sandwiches. The key to staying ahead in this space will be the ability to adapt to these changing demands while maintaining the core values of quality, convenience, and sustainability.

In conclusion, the dual voltage revolution in sandwich presses is a testament to the power of innovation and the importance of meeting consumer needs. By embracing this revolution, manufacturers are not only expanding their market reach but also setting the stage for a new era of kitchen appliances that are versatile, efficient, and user-friendly. As we move forward, the potential for growth and advancement in the sandwich press OEM space is vast, and those who embrace the dual voltage revolution will undoubtedly be at the forefront of this exciting new chapter in kitchen technology.